Page 54: of Maritime Reporter Magazine (April 2021)

Offshore Wind Energy: Installation, Crew & Supply Vessels

Read this page in Pdf, Flash or Html5 edition of April 2021 Maritime Reporter Magazine

In the Shipyard

New vessels, contracts and designs

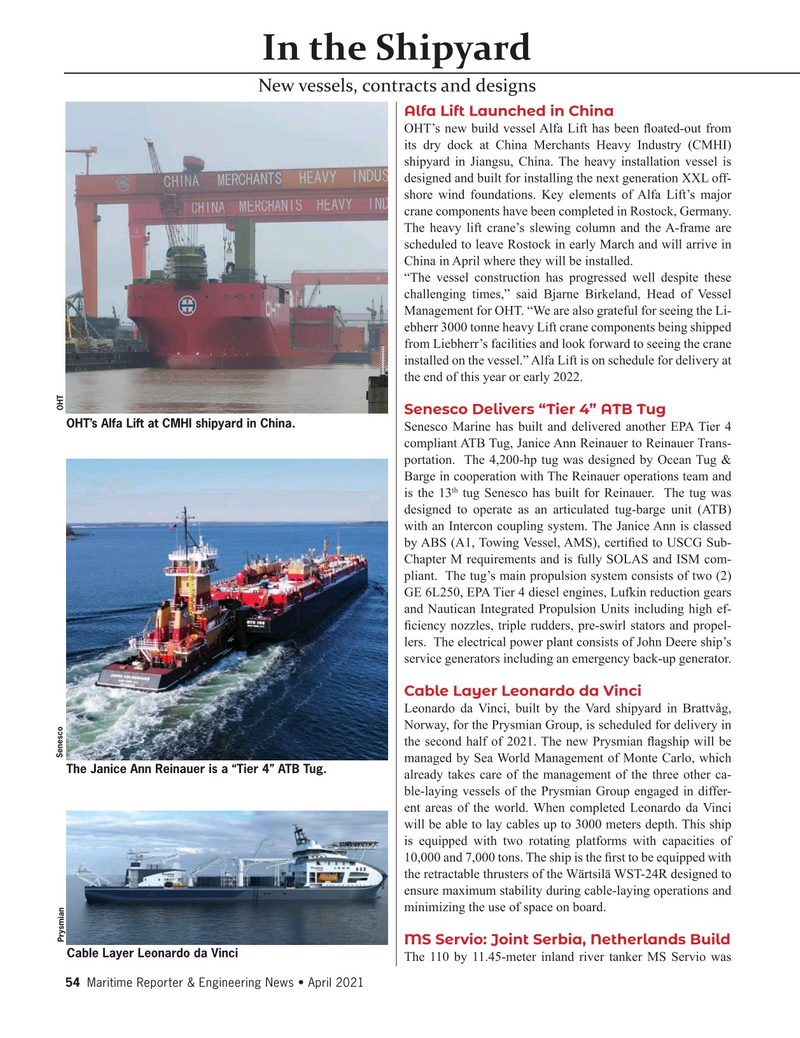

Alfa Lift Launched in China

OHT’s new build vessel Alfa Lift has been ? oated-out from its dry dock at China Merchants Heavy Industry (CMHI) shipyard in Jiangsu, China. The heavy installation vessel is designed and built for installing the next generation XXL off- shore wind foundations. Key elements of Alfa Lift’s major crane components have been completed in Rostock, Germany.

The heavy lift crane’s slewing column and the A-frame are scheduled to leave Rostock in early March and will arrive in

China in April where they will be installed.

“The vessel construction has progressed well despite these challenging times,” said Bjarne Birkeland, Head of Vessel

Management for OHT. “We are also grateful for seeing the Li- ebherr 3000 tonne heavy Lift crane components being shipped from Liebherr’s facilities and look forward to seeing the crane installed on the vessel.” Alfa Lift is on schedule for delivery at the end of this year or early 2022.

Senesco Delivers “Tier 4” ATB Tug

OHT’s Alfa Lift at CMHI shipyard in China.

Senesco Marine has built and delivered another EPA Tier 4 compliant ATB Tug, Janice Ann Reinauer to Reinauer Trans- portation. The 4,200-hp tug was designed by Ocean Tug &

Barge in cooperation with The Reinauer operations team and th is the 13 tug Senesco has built for Reinauer. The tug was designed to operate as an articulated tug-barge unit (ATB) with an Intercon coupling system. The Janice Ann is classed by ABS (A1, Towing Vessel, AMS), certi? ed to USCG Sub-

Chapter M requirements and is fully SOLAS and ISM com- pliant. The tug’s main propulsion system consists of two (2)

GE 6L250, EPA Tier 4 diesel engines, Lufkin reduction gears and Nautican Integrated Propulsion Units including high ef- ? ciency nozzles, triple rudders, pre-swirl stators and propel- lers. The electrical power plant consists of John Deere ship’s service generators including an emergency back-up generator.

Cable Layer Leonardo da Vinci

Leonardo da Vinci, built by the Vard shipyard in Brattvåg,

Norway, for the Prysmian Group, is scheduled for delivery in the second half of 2021. The new Prysmian ? agship will be Senesco Prysmian OHT managed by Sea World Management of Monte Carlo, which

The Janice Ann Reinauer is a “Tier 4” ATB Tug.

already takes care of the management of the three other ca- ble-laying vessels of the Prysmian Group engaged in differ- ent areas of the world. When completed Leonardo da Vinci will be able to lay cables up to 3000 meters depth. This ship is equipped with two rotating platforms with capacities of 10,000 and 7,000 tons. The ship is the ? rst to be equipped with the retractable thrusters of the Wärtsilä WST-24R designed to ensure maximum stability during cable-laying operations and minimizing the use of space on board.

MS Servio: Joint Serbia, Netherlands Build Cable Layer Leonardo da Vinci

The 110 by 11.45-meter inland river tanker MS Servio was 54 Maritime Reporter & Engineering News • April 2021

MR #4 (50-59).indd 54 4/1/2021 1:34:38 PM

53

53

55

55