Page 49: of Maritime Reporter Magazine (June 2021)

USCG Fleet Modernization Annual

Read this page in Pdf, Flash or Html5 edition of June 2021 Maritime Reporter Magazine

TECH FEATURE BIOFOULING ernative for Biofouling Control not to clean their hulls even when a or in drydock for an in-service vessel. the bene? ts of a hard cleanable surface heavy layer of slime has built up. Heavy However, these coatings offer no anti- while obtaining signi? cant fuel savings slime on a ship’s hull has an associated fouling or foul release properties which from its foul release properties with- fuel/power penalty which in some cases contributes to a high surface roughness out leaching biocides or silicone oils. [1] can be as high as 20% . when compared to the other systems XGIT-Fuel is speci? cally designed to be

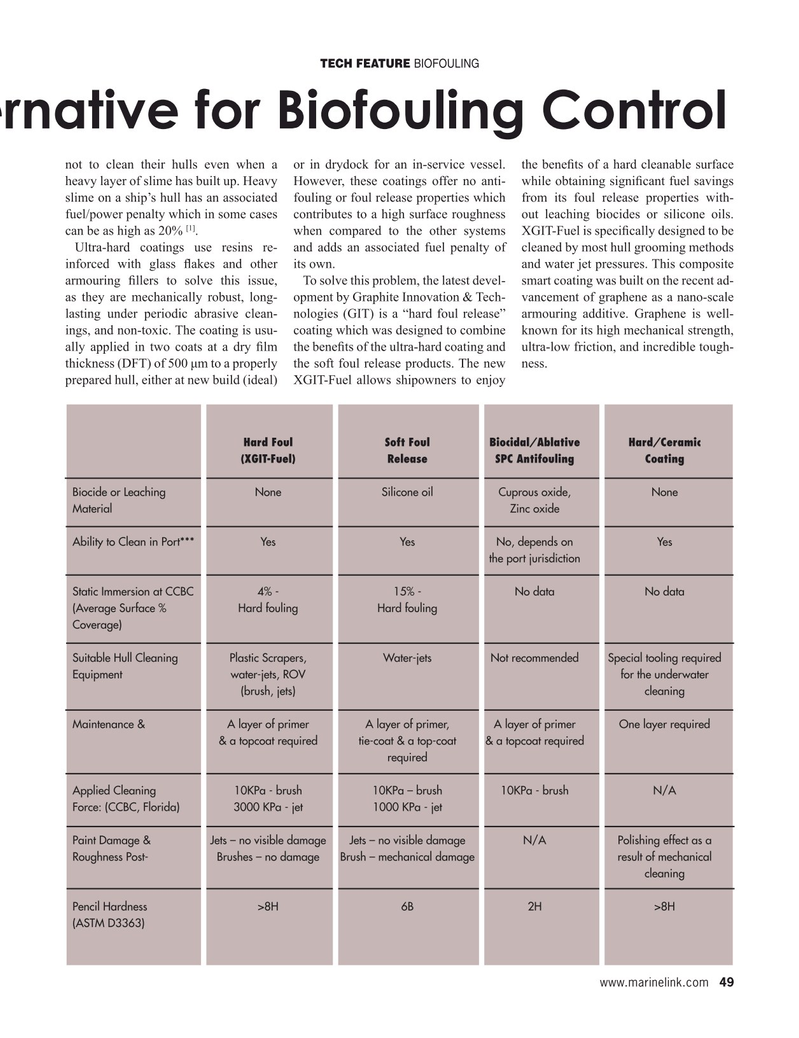

Ultra-hard coatings use resins re- and adds an associated fuel penalty of cleaned by most hull grooming methods inforced with glass ? akes and other its own. and water jet pressures. This composite armouring ? llers to solve this issue, To solve this problem, the latest devel- smart coating was built on the recent ad- as they are mechanically robust, long- opment by Graphite Innovation & Tech- vancement of graphene as a nano-scale lasting under periodic abrasive clean- nologies (GIT) is a “hard foul release” armouring additive. Graphene is well- ings, and non-toxic. The coating is usu- coating which was designed to combine known for its high mechanical strength, ally applied in two coats at a dry ? lm the bene? ts of the ultra-hard coating and ultra-low friction, and incredible tough- thickness (DFT) of 500 µm to a properly the soft foul release products. The new ness. prepared hull, either at new build (ideal) XGIT-Fuel allows shipowners to enjoy Hard Foul Soft Foul Biocidal/Ablative Hard/Ceramic (XGIT-Fuel) Release SPC Antifouling Coating

Biocide or Leaching None Silicone oil Cuprous oxide, None

Material Zinc oxide

Ability to Clean in Port*** Yes Yes No, depends on Yes the port jurisdiction

Static Immersion at CCBC 4% - 15% - No data No data (Average Surface % Hard fouling Hard fouling

Coverage)

Suitable Hull Cleaning Plastic Scrapers, Water-jets Not recommended Special tooling required

Equipment water-jets, ROV for the underwater (brush, jets) cleaning

Maintenance & A layer of primer A layer of primer, A layer of primer One layer required & a topcoat required tie-coat & a top-coat & a topcoat required required

Applied Cleaning 10KPa - brush 10KPa – brush 10KPa - brush N/A

Force: (CCBC, Florida) 3000 KPa - jet 1000 KPa - jet

Paint Damage & Jets – no visible damage Jets – no visible damage N/A Polishing effect as a

Roughness Post- Brushes – no damage Brush – mechanical damage result of mechanical cleaning

Pencil Hardness >8H 6B 2H >8H (ASTM D3363) www.marinelink.com 49

MR #6 (34-49).indd 49 6/4/2021 5:09:10 PM

48

48

50

50