Page 50: of Maritime Reporter Magazine (June 2021)

USCG Fleet Modernization Annual

Read this page in Pdf, Flash or Html5 edition of June 2021 Maritime Reporter Magazine

TECH FEATURE BIOFOULING

Figure 1: Static biofouling growth of Hard

Foul Release (white panel), polyvinyl chloride (PVC) negative control, and a soft foul release coating.

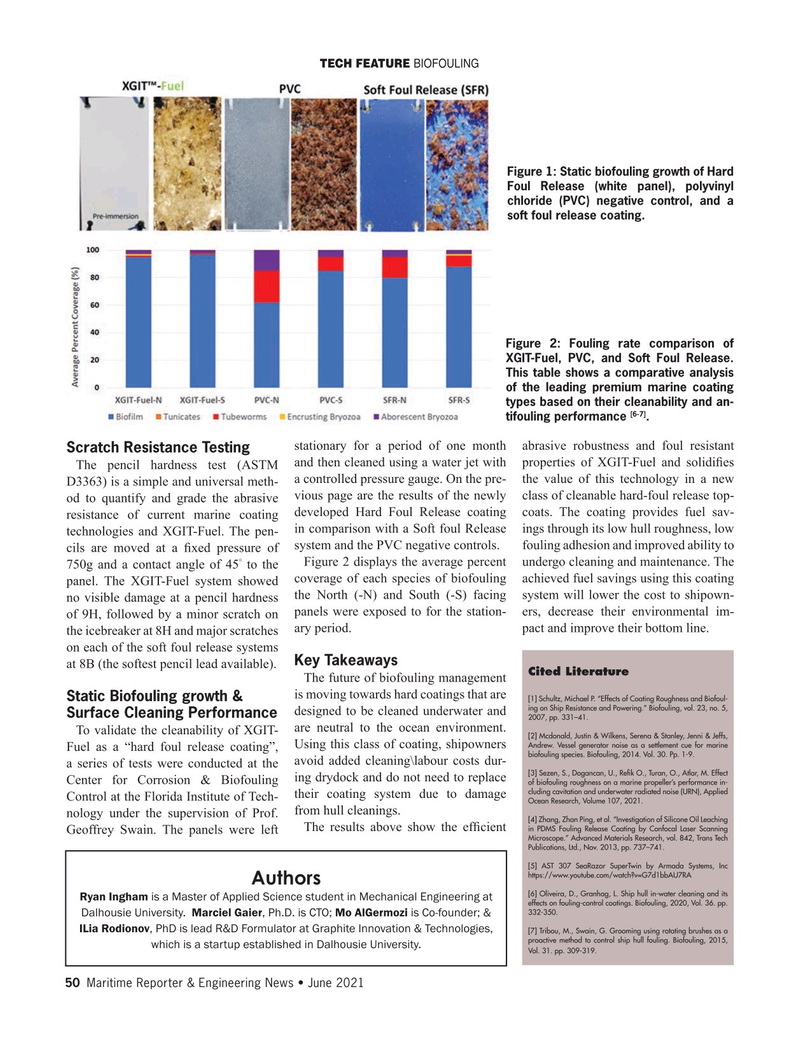

Figure 2: Fouling rate comparison of

XGIT-Fuel, PVC, and Soft Foul Release.

This table shows a comparative analysis of the leading premium marine coating types based on their cleanability and an- [6-7] tifouling performance .

stationary for a period of one month abrasive robustness and foul resistant

Scratch Resistance Testing

The pencil hardness test (ASTM and then cleaned using a water jet with properties of XGIT-Fuel and solidi? es a controlled pressure gauge. On the pre- the value of this technology in a new

D3363) is a simple and universal meth- od to quantify and grade the abrasive vious page are the results of the newly class of cleanable hard-foul release top- resistance of current marine coating developed Hard Foul Release coating coats. The coating provides fuel sav- in comparison with a Soft foul Release ings through its low hull roughness, low technologies and XGIT-Fuel. The pen- cils are moved at a ? xed pressure of system and the PVC negative controls. fouling adhesion and improved ability to °

Figure 2 displays the average percent undergo cleaning and maintenance. The 750g and a contact angle of 45 to the panel. The XGIT-Fuel system showed coverage of each species of biofouling achieved fuel savings using this coating no visible damage at a pencil hardness the North (-N) and South (-S) facing system will lower the cost to shipown- of 9H, followed by a minor scratch on panels were exposed to for the station- ers, decrease their environmental im- ary period. pact and improve their bottom line.

the icebreaker at 8H and major scratches on each of the soft foul release systems

Key Takeaways at 8B (the softest pencil lead available).

Cited Literature

The future of biofouling management is moving towards hard coatings that are

Static Biofouling growth & [1] Schultz, Michael P. “Effects of Coating Roughness and Biofoul- ing on Ship Resistance and Powering.” Biofouling, vol. 23, no. 5, designed to be cleaned underwater and

Surface Cleaning Performance 2007, pp. 331–41. are neutral to the ocean environment.

To validate the cleanability of XGIT- [2] Mcdonald, Justin & Wilkens, Serena & Stanley, Jenni & Jeffs,

Andrew. Vessel generator noise as a settlement cue for marine

Fuel as a “hard foul release coating”, Using this class of coating, shipowners biofouling species. Biofouling, 2014. Vol. 30. Pp. 1-9. a series of tests were conducted at the avoid added cleaning\labour costs dur- [3] Sezen, S., Dogancan, U., Re? k O., Turan, O., Atlar, M. Effect

Center for Corrosion & Biofouling ing drydock and do not need to replace of biofouling roughness on a marine propeller’s performance in- cluding cavitation and underwater radiated noise (URN), Applied their coating system due to damage

Control at the Florida Institute of Tech-

Ocean Research, Volume 107, 2021.

nology under the supervision of Prof. from hull cleanings. [4] Zhang, Zhan Ping, et al. “Investigation of Silicone Oil Leaching

The results above show the ef? cient in PDMS Fouling Release Coating by Confocal Laser Scanning

Geoffrey Swain. The panels were left

Microscope.” Advanced Materials Research, vol. 842, Trans Tech

Publications, Ltd., Nov. 2013, pp. 737–741. [5] AST 307 SeaRazor SuperTwin by Armada Systems, Inc https://www.youtube.com/watch?v=G7d1bbAU7RA

Authors [6] Oliveira, D., Granhag, L. Ship hull in-water cleaning and its

Ryan Ingham is a Master of Applied Science student in Mechanical Engineering at effects on fouling-control coatings. Biofouling, 2020, Vol. 36. pp. 332-350.

Dalhousie University. Marciel Gaier, Ph.D. is CTO; Mo AlGermozi is Co-founder; &

ILia Rodionov, PhD is lead R&D Formulator at Graphite Innovation & Technologies, [7] Tribou, M., Swain, G. Grooming using rotating brushes as a proactive method to control ship hull fouling. Biofouling, 2015, which is a startup established in Dalhousie University.

Vol. 31. pp. 309-319. 50 Maritime Reporter & Engineering News • June 2021

MR #6 (50-58).indd 50 6/4/2021 11:30:43 AM

49

49

51

51