Page 54: of Maritime Reporter Magazine (September 2023)

Marine Design Edition

Read this page in Pdf, Flash or Html5 edition of September 2023 Maritime Reporter Magazine

TECH FOCUS: WELDING

Weld Engineering Services Help

Enhance Vessel Functionality,

Durability and Longevity

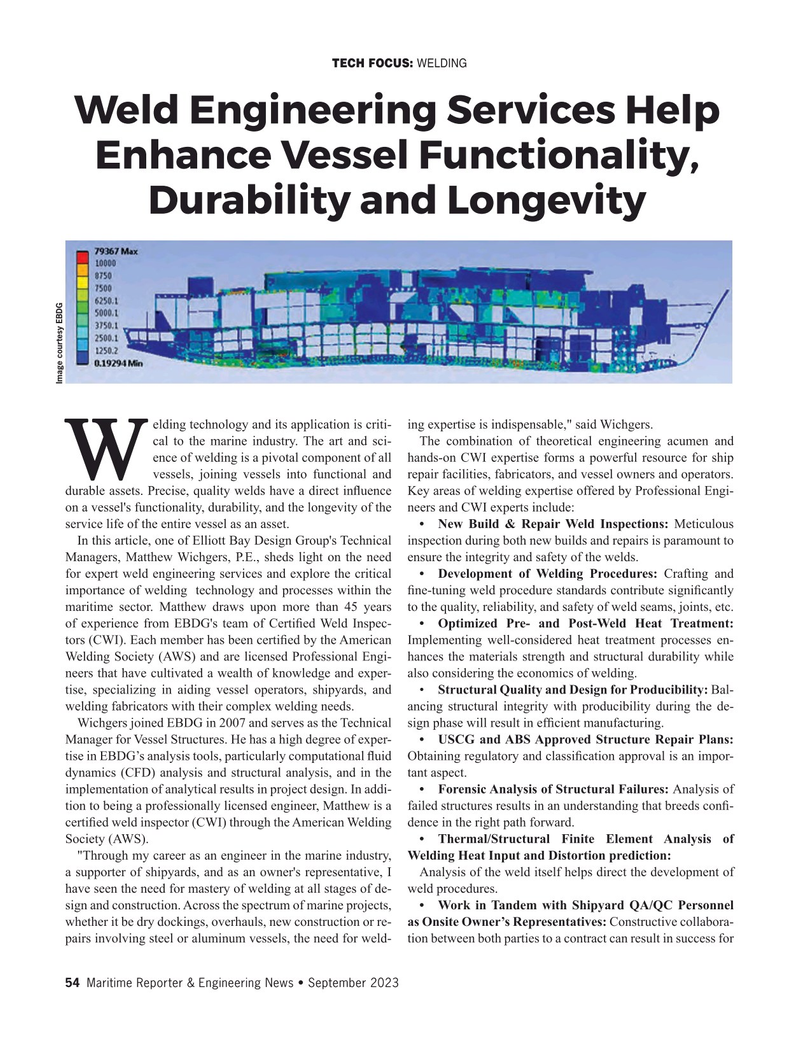

Image courtesy EBDG elding technology and its application is criti- ing expertise is indispensable," said Wichgers.

cal to the marine industry. The art and sci- The combination of theoretical engineering acumen and ence of welding is a pivotal component of all hands-on CWI expertise forms a powerful resource for ship

Wvessels, joining vessels into functional and repair facilities, fabricators, and vessel owners and operators. durable assets. Precise, quality welds have a direct in? uence Key areas of welding expertise offered by Professional Engi- on a vessel's functionality, durability, and the longevity of the neers and CWI experts include: service life of the entire vessel as an asset. • New Build & Repair Weld Inspections: Meticulous

In this article, one of Elliott Bay Design Group's Technical inspection during both new builds and repairs is paramount to

Managers, Matthew Wichgers, P.E., sheds light on the need ensure the integrity and safety of the welds.

for expert weld engineering services and explore the critical • Development of Welding Procedures: Crafting and importance of welding technology and processes within the ? ne-tuning weld procedure standards contribute signi? cantly maritime sector. Matthew draws upon more than 45 years to the quality, reliability, and safety of weld seams, joints, etc.

of experience from EBDG's team of Certi? ed Weld Inspec- • Optimized Pre- and Post-Weld Heat Treatment: tors (CWI). Each member has been certi? ed by the American Implementing well-considered heat treatment processes en-

Welding Society (AWS) and are licensed Professional Engi- hances the materials strength and structural durability while neers that have cultivated a wealth of knowledge and exper- also considering the economics of welding.

tise, specializing in aiding vessel operators, shipyards, and • Structural Quality and Design for Producibility: Bal- welding fabricators with their complex welding needs. ancing structural integrity with producibility during the de-

Wichgers joined EBDG in 2007 and serves as the Technical sign phase will result in ef? cient manufacturing.

Manager for Vessel Structures. He has a high degree of exper- • USCG and ABS Approved Structure Repair Plans: tise in EBDG’s analysis tools, particularly computational ? uid Obtaining regulatory and classi? cation approval is an impor- dynamics (CFD) analysis and structural analysis, and in the tant aspect.

implementation of analytical results in project design. In addi- • Forensic Analysis of Structural Failures: Analysis of tion to being a professionally licensed engineer, Matthew is a failed structures results in an understanding that breeds con? - certi? ed weld inspector (CWI) through the American Welding dence in the right path forward.

Society (AWS). • Thermal/Structural Finite Element Analysis of "Through my career as an engineer in the marine industry, Welding Heat Input and Distortion prediction: a supporter of shipyards, and as an owner's representative, I Analysis of the weld itself helps direct the development of have seen the need for mastery of welding at all stages of de- weld procedures.

sign and construction. Across the spectrum of marine projects, • Work in Tandem with Shipyard QA/QC Personnel whether it be dry dockings, overhauls, new construction or re- as Onsite Owner’s Representatives: Constructive collabora- pairs involving steel or aluminum vessels, the need for weld- tion between both parties to a contract can result in success for 54 Maritime Reporter & Engineering News • September 2023

MR #9 (50-60).indd 54 9/6/2023 5:04:34 PM

53

53

55

55