Page 45: of Offshore Engineer Magazine (Dec/Jan 2013)

Read this page in Pdf, Flash or Html5 edition of Dec/Jan 2013 Offshore Engineer Magazine

determining the volumetric behavior of

Subsea reservoir fuids as they pass through the separator. However, production often has to be ceased in order to conduct a well test, which has a negative impact on the feld’s economics.

The process can also lead to potential inaccuracies on longer pipelines, and where lower pressures decrease PVT accuracy.

Subsea sampling, the alternative to well testing, has also come with limita- tions. These include samples being taken randomly and topside; little consideration for fow dynamics; an inability to track and react to fuctuat- ing reservoir conditions, such as high gas volume fractions (GVF), oil in water content and increased salinity; and a failure to maintain original pressure conditions in the laboratory.

Conventional PVT analysis can take weeks to be delivered and can be based on a limited number of samples, which are retrieved through wireline sampling

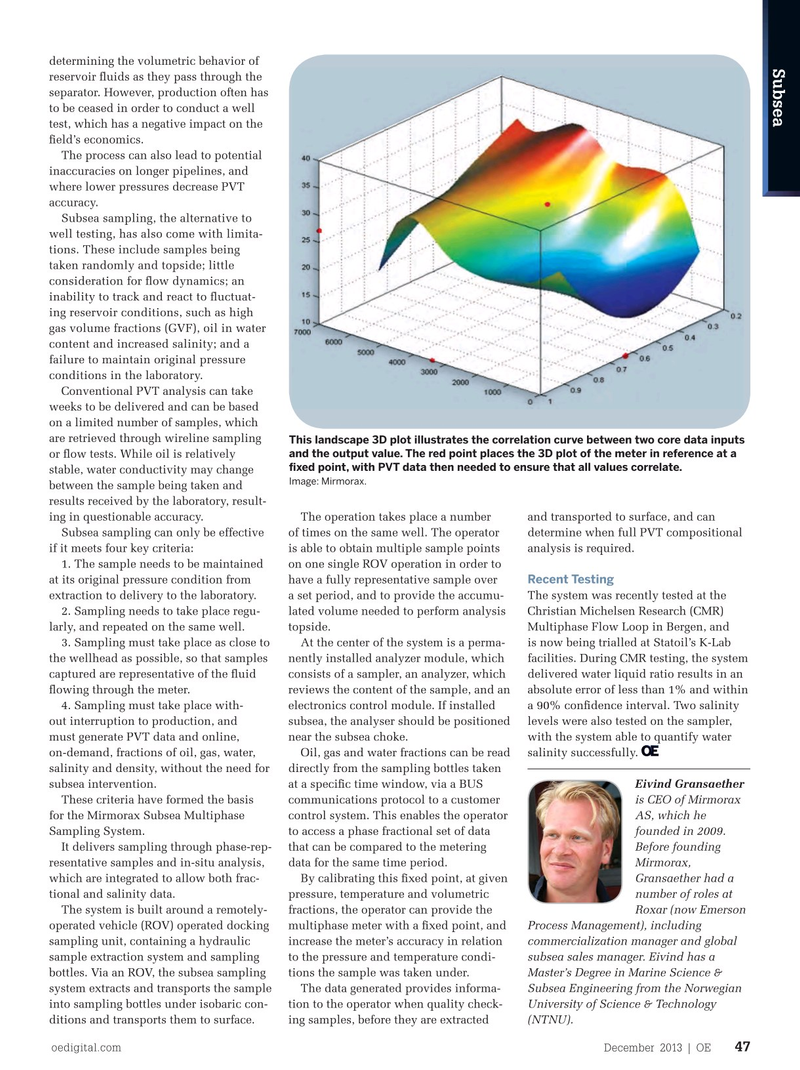

This landscape 3D plot illustrates the correlation curve between two core data inputs and the output value. The red point places the 3D plot of the meter in reference at a or fow tests. While oil is relatively fxed point, with PVT data then needed to ensure that all values correlate. stable, water conductivity may change

Image: Mirmorax.

between the sample being taken and results received by the laboratory, result- ing in questionable accuracy. The operation takes place a number and transported to surface, and can

Subsea sampling can only be effective of times on the same well. The operator determine when full PVT compositional if it meets four key criteria: is able to obtain multiple sample points analysis is required. 1. The sample needs to be maintained on one single ROV operation in order to

Recent Testing at its original pressure condition from have a fully representative sample over extraction to delivery to the laboratory. a set period, and to provide the accumu- The system was recently tested at the 2. Sampling needs to take place regu- lated volume needed to perform analysis Christian Michelsen Research (CMR) larly, and repeated on the same well. topside. Multiphase Flow Loop in Bergen, and 3. Sampling must take place as close to At the center of the system is a perma- is now being trialled at Statoil’s K-Lab the wellhead as possible, so that samples nently installed analyzer module, which facilities. During CMR testing, the system captured are representative of the fuid consists of a sampler, an analyzer, which delivered water liquid ratio results in an fowing through the meter. reviews the content of the sample, and an absolute error of less than 1% and within 4. Sampling must take place with- electronics control module. If installed a 90% confdence interval. Two salinity out interruption to production, and subsea, the analyser should be positioned levels were also tested on the sampler, must generate PVT data and online, near the subsea choke. with the system able to quantify water on-demand, fractions of oil, gas, water, Oil, gas and water fractions can be read salinity successfully. salinity and density, without the need for directly from the sampling bottles taken subsea intervention. at a specifc time window, via a BUS Eivind Gransaether

These criteria have formed the basis communications protocol to a customer is CEO of Mirmorax for the Mirmorax Subsea Multiphase control system. This enables the operator AS, which he

Sampling System. to access a phase fractional set of data founded in 2009.

It delivers sampling through phase-rep- that can be compared to the metering Before founding resentative samples and in-situ analysis, data for the same time period. Mirmorax, which are integrated to allow both frac- By calibrating this fxed point, at given Gransaether had a tional and salinity data. pressure, temperature and volumetric number of roles at

The system is built around a remotely- fractions, the operator can provide the Roxar (now Emerson operated vehicle (ROV) operated docking multiphase meter with a fxed point, and Process Management), including sampling unit, containing a hydraulic increase the meter’s accuracy in relation commercialization manager and global sample extraction system and sampling to the pressure and temperature condi- subsea sales manager. Eivind has a bottles. Via an ROV, the subsea sampling tions the sample was taken under. Master’s Degree in Marine Science & system extracts and transports the sample The data generated provides informa- Subsea Engineering from the Norwegian into sampling bottles under isobaric con- tion to the operator when quality check- University of Science & Technology ditions and transports them to surface. ing samples, before they are extracted (NTNU).

oedigital.com December 2013 | OE 47 046_OE1213_Subsea1.indd 47 11/22/13 6:52 PM

44

44

46

46