Page 22: of Offshore Engineer Magazine (Sep/Oct 2016)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2016 Offshore Engineer Magazine

for Nigeria, and Perdido is the deepest drilling and produc-

FPSO tion system in the world. And now Stones will be the deepest production system anywhere (in 9500ft of water).”

Lohr says that with Stones, Shell opted to have contractor

SBM Offshore design the facility, with the Shell providing the functional speci? cations.

“For Shell, most of our experience in the deepwater Gulf of Mexico has been with TLP hosts. Perdido being an excep- tion,” Lohr says. “There was a learning curve, but (in terms of working with the US Bureau of Safety and Environmental

Enforcement) they had the advantage of working with

Petrobras (on Cascade/Chinook).”

In July 2013, Netherlands-based ? oating production contrac- tor SBM Offshore was chosen to supply and lease the Stones

FPSO, Turritella, which is a converted 159,000-dwt Suezmax tanker. The Turritella will be capable of producing 60,000 b/d of oil and 15 MMcf/d of gas. The hull will be able to store 800,000 bbl of oil.

At the time the contract was signed with Shell, SBM

Offshore said the Turritella will be moored using buoyant tur- ret mooring (BTM) technology, allowing the vessel to weather- vane on location or to disconnect in the event of a hurricane.

Steel lazy-wave risers (SLWRs) connecting the subsea facili- ties to the BTM will be used for the ? rst time with a discon- nectable FPSO, the company said at the time. Shell indicated the SLWRs have an arch bend, which absorbs the motion of the FPSO and boosts riser performance at extreme depths.

Lohr says that Shell has used both disconnectable FPSOs and SLWRs before, and for the ? rst time brought these tech- nologies together for the Stones project.

“For the SLWRs, we actually install buoyancy on the risers, so there’s a S-shape to them that helps to take some of the load off the buoy and the FPSO. We have used it before on other projects and we felt comfortable with this technology,” he says.

The Turritella underwent conversion work at Keppel

Shipyard in Singapore with teams from SBM Offshore and

Shell present.

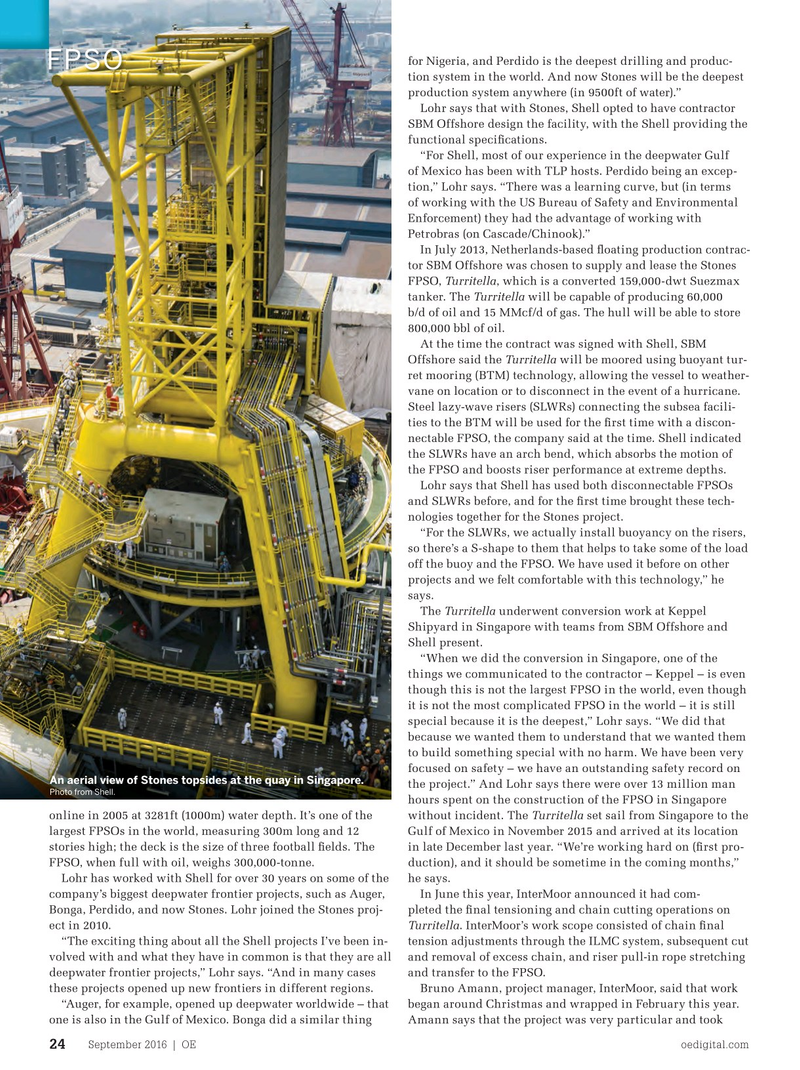

“When we did the conversion in Singapore, one of the things we communicated to the contractor – Keppel – is even though this is not the largest FPSO in the world, even though it is not the most complicated FPSO in the world – it is still special because it is the deepest,” Lohr says. “We did that because we wanted them to understand that we wanted them to build something special with no harm. We have been very focused on safety – we have an outstanding safety record on

An aerial view of Stones topsides at the quay in Singapore. the project.” And Lohr says there were over 13 million man

Photo from Shell.

hours spent on the construction of the FPSO in Singapore online in 2005 at 3281ft (1000m) water depth. It’s one of the without incident. The Turritella set sail from Singapore to the largest FPSOs in the world, measuring 300m long and 12 Gulf of Mexico in November 2015 and arrived at its location stories high; the deck is the size of three football ? elds. The in late December last year. “We’re working hard on (? rst pro-

FPSO, when full with oil, weighs 300,000-tonne. duction), and it should be sometime in the coming months,”

Lohr has worked with Shell for over 30 years on some of the he says. company’s biggest deepwater frontier projects, such as Auger, In June this year, InterMoor announced it had com-

Bonga, Perdido, and now Stones. Lohr joined the Stones proj- pleted the ? nal tensioning and chain cutting operations on ect in 2010. Turritella. InterMoor’s work scope consisted of chain ? nal “The exciting thing about all the Shell projects I’ve been in- tension adjustments through the ILMC system, subsequent cut volved with and what they have in common is that they are all and removal of excess chain, and riser pull-in rope stretching deepwater frontier projects,” Lohr says. “And in many cases and transfer to the FPSO.

these projects opened up new frontiers in different regions. Bruno Amann, project manager, InterMoor, said that work “Auger, for example, opened up deepwater worldwide – that began around Christmas and wrapped in February this year. one is also in the Gulf of Mexico. Bonga did a similar thing Amann says that the project was very particular and took

September 2016 | OE oedigital.com 24 022_OE0916_ Feature1_Audrey.indd 24 8/24/16 12:57 PM

21

21

23

23