Page 44: of Offshore Engineer Magazine (Mar/Apr 2021)

Offshore Wind Outlook

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2021 Offshore Engineer Magazine

TECH FILE SUBSEA SIM AND TESTING

In subsea applications, if a BOP component fails, days can be

Pilot Valves lost retrieving, repairing and redeploying the BOP stack. When that happens outside of planned maintenance, it can cost hun- dreds of thousands or even millions of dollars in lost productiv- ity, applying heavy economic pressure on the drilling contractor operating the rig and the operator funding the drilling activity.

Mitigate Challenges Trough Simulation

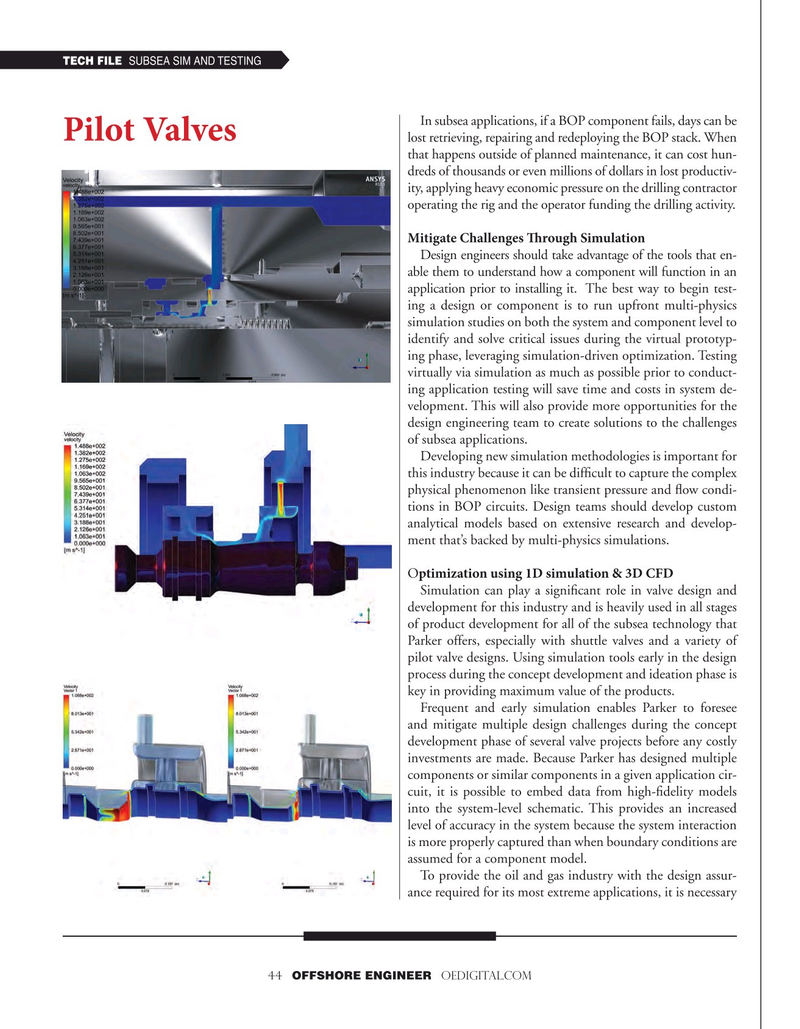

Design engineers should take advantage of the tools that en- able them to understand how a component will function in an application prior to installing it. The best way to begin test- ing a design or component is to run upfront multi-physics simulation studies on both the system and component level to identify and solve critical issues during the virtual prototyp- ing phase, leveraging simulation-driven optimization. Testing virtually via simulation as much as possible prior to conduct- ing application testing will save time and costs in system de- velopment. This will also provide more opportunities for the design engineering team to create solutions to the challenges of subsea applications.

Developing new simulation methodologies is important for this industry because it can be diffcult to capture the complex physical phenomenon like transient pressure and fow condi- tions in BOP circuits. Design teams should develop custom analytical models based on extensive research and develop- ment that’s backed by multi-physics simulations.

Optimization using 1D simulation & 3D CFD

Simulation can play a signifcant role in valve design and development for this industry and is heavily used in all stages of product development for all of the subsea technology that

Parker offers, especially with shuttle valves and a variety of pilot valve designs. Using simulation tools early in the design process during the concept development and ideation phase is key in providing maximum value of the products.

Frequent and early simulation enables Parker to foresee and mitigate multiple design challenges during the concept development phase of several valve projects before any costly investments are made. Because Parker has designed multiple components or similar components in a given application cir- cuit, it is possible to embed data from high-fdelity models into the system-level schematic. This provides an increased level of accuracy in the system because the system interaction is more properly captured than when boundary conditions are assumed for a component model.

To provide the oil and gas industry with the design assur- ance required for its most extreme applications, it is necessary 44 OFFSHORE ENGINEER OEDIGITAL.COM

43

43

45

45