Cummins

-

- Interview: Edmonds Brown, Cummins, Inc. Maritime Reporter, May 2019 #46

The May 2019 edition of Maritime Reporter & Engineering News features a eight-page feature section on "Thought Leadership" in the marine power sector. Here we extract and present the interview with Edmonds Brown, Cummins, Inc., Commercial Marine Segment Leader.

Please put in perspective and discuss the current environment and pressure to reduce emissions in the maritime industry.

When I started in the marine industry, my primary focus was working to achieve certification of Cummins’ marine engines for U.S. Environmental Protection Agency (EPA) Tier 1 and International Marine Organization (IMO) Tier I standards. Back then, there was a single solution to meet all the regulations. This was not only easier on engine manufacturers, it was easier on the fleet owners, too, providing them with only one system to implement and maintain.Since then, not only have emissions regulations gotten more stringent, but they are also increasingly siloed, making it difficult to scale research and development across platforms. On the surface, today’s emissions regulations appear to have similarities. But in reality, they are very different. At the same time, the landscape is continuing to diverge, with more regulations, such as China stage 1 and 2, taking effect. Each regulation is distinct and challenging, which, from a solutions perspective, means each requires a lot of work.

This presents a business challenge as well. It could be difficult to make the business case to offer options to meet every regulation on every engine. Since the regulations are different, it’s difficult to scale a single project to comply with every standard, every time. We have also seen the cycle between regulations decreasing, meaning that once you meet current regulations, you already need to focus on developing solutions to meet the next standards.

This isn’t unique to engine manufacturers. Fleet owners and operators also feel the challenge. As regulations change, ship designs must also be adapted. This means the fleet isn’t standardized and it’s difficult to consider lessons on emissions from previous generations of vessels.

At Cummins, our development often builds on existing platforms. This enables us to build on existing solutions, which helps our customers standardize their fleets as much as possible.

How does this pressure compare to the other industries you serve? What technologies or ‘lessons learned’ from other industries are you applying to maritime solutions? Please be specific.Cummins is much more than a marine business. Our company is a diversified business that participates in many market segments. This allows us to leverage significant investments across numerous segments and platforms and benefit from knowledge and experience gained over thousands of product launches

All markets that Cummins serves have emissions regulations. Being involved in so many diverse segments on a global scale is a strength when looking at how we can adapt solutions for use in the maritime industry. For example, Cummins has been involved in meeting complex on-highway emissions for more than 20 years. Our early adaptation of aftertreatment solutions for the on-highway market, whose strict emissions regulations are ahead of most, has carried over to our marine solutions.

In addition, our Cummins Emission Solutions business delivers products not just for Cummins’ engines, but for engines built by other companies, too. The technology they develop really distinguishes us. Even some of our competitors use these products in different segments.

Photo Courtesy Cummins MarineWhile I’m certain that your organization’s investment in Research & Development is broad and continuous, can you point to one or two areas where you are investing most heavily, explaining why?

Photo Courtesy Cummins MarineWhile I’m certain that your organization’s investment in Research & Development is broad and continuous, can you point to one or two areas where you are investing most heavily, explaining why?Emissions control, across our business, is an area where Cummins is investing time, energy, and money. Given the diverse standards we must meet – not just in marine, but in all of our segments around the world – we are making significant investments to meet evolving regulations.

Four to five unique regulations drive work on our marine engine platforms alone. When you look at how many engine platforms Cummins has across all its business segments, and multiply that by the unique emissions regulations that we need to meet, you begin to see how expansive and all-encompassing meeting emissions regulations can be.At Cummins our strategy is to develop diversified and dependable power solutions. One of the ways the company is doing that is through electrification. Cummins plans to be a leader in electrified power and we believe this business segment will provide the innovation and focus to ensure future success.

We started work on electric powertrains long before the Electrified Power business started last year and we have been working with electrification for decades in areas such as hybrid engines. Cummins is focusing initially on full electrification in the urban bus and truck markets because that’s where we think the infrastructure for electrification will develop first.

But you can see the results of the company’s work with hybrid engines in the marine market. Examples include Enhydra, a large excursion boat, which was named Professional Mariner’s 2019 Boat of the Year, and Skipsteknisk’s new stern trawler, an IMO III vessel which uses electricity to power the ship’s fish factory, freezing machinery and quarters for the ship’s crew.

FUEL: There is justifiably vibrant discussion surrounding fuel choice. Do you see one fuel emerging today as the ‘next big thing?’

Diesel continues to be the most viable fuel right now and probably in the foreseeable future for our marine customers. While there are ongoing discussions around alternative fuel sources, such as natural gas, LNG, methane, and electric, there is no one standout among them. For the industry to switch, mariners will want to see that a new fuel is a viable and dependable option, and that the global infrastructure exists to support it.

If diesel prices were to increase, it could possibly open the market to wider adaptation alternatives such as LNG. But it would require a massive updating in infrastructure within the shipping industry for alternatives to be used on a wide scale. The good news is that the low-quality diesel fuel that has been used by the marine industry for decades is now being blended with cleaner, higher quality fuel to help meet tougher emissions standards around the world.

There can be significant variations in blending. With ships bunkering in different regions of the world, blends are not necessarily compatible and quality can be inconsistent. That’s where our Fleetguard fuel filters and other technologies can play an important role in helping out customers meet regulations.

The combination of improved fuels and the innovation we discussed earlier in exhaust aftertreatment has made a huge difference in the on-highway market and I think it can make a difference in marine, too. That means we can still make a positive impact on the environment today while determining if any alternative fuel source will get us where we want to go tomorrow.

Put in perspective ‘Autonomous Marine Operations’. Is it a real conversation with your clients today, or a topic far in the future? How is your organization preparing for the advent of autonomy in the maritime space?The traditional definition of an autonomous vessel piloting itself across the ocean means very little to the engine. But when you look at the broader need for less human interaction for maintenance, diagnostics and repairs, this is where Cummins has been working with customers to adapt, develop, and implement technology.

Imagine an engine that requires less human touch. An engine controlled remotely, running longer between service intervals, performing standard maintenance on itself and diagnosing its own problems. Cummins is already deploying this kind of technology across various platforms.

I think there are pockets where autonomous marine operations make sense today, but as far as widespread adoption in the marine industry goes, there are still many factors to consider.

Photo Courtesy Cummins MarineFrom an engineering, design & manufacturing perspective, what do you count as the biggest challenge today to produce innovative, next-generation propulsion plants that meet or beat emission regulation.

Photo Courtesy Cummins MarineFrom an engineering, design & manufacturing perspective, what do you count as the biggest challenge today to produce innovative, next-generation propulsion plants that meet or beat emission regulation.At Cummins, we believe tough but fair regulations can be a key factor in driving innovation. Regulations can create clear goals and a level playing field for companies to innovate. But the regulations must be enforced. If enforcement is inconsistent, the only loser is the one who complies.

Our Government Relations team meets with policy makers around the world talking about how economic development and competitiveness can flourish when regulations are clear and enforceable. Unfortunately, as I said earlier, they vary widely in the marine industry from country to country and region to region, ranging from strict standards to almost no requirements.Our customers must consider what regulations they will need to meet when they build a new vessel and that can lead to variations within their fleets and our supply chain that complicate a whole host of issues including maintenance and product lifecycles.

Fortunately, as the potential impacts of emissions on our environment becomes increasingly clear, more and more countries are embracing tougher standards. In areas other than marine, we’re seeing more consistency and that bodes well for innovation and the future. But even more consistency would make it easier for companies in our industry to innovate.

The IMO last year dropped the gauntlet to reduce maritime emissions 50% by 2050. Is that target achievable, and if so, which fuels or technologies will be key to success? Same Question as above, but comment on the prospects of zero carbon emissions?Our culture of innovation at Cummins and the company’s focus on sustainability makes me optimistic about the future. We have made some incredible strides in emissions aftertreatment across many different markets using many different platforms. Cummins is working on its own environmental sustainability plan right now tied to 2050 that will be announced later this year. So, it’s a topic getting a lot of attention at every level of our company.

In addition, technical innovation is happening faster now than maybe at any time in our company’s 100-year history. So, it’s hard to predict what technology we’ll use or the fuels that will get us where we want to go.

Cummins wants to bring to customers a broad portfolio of solutions to their power needs, including clean diesel, natural gas, electrified power or, in the future, some fuel source maybe we don’t even know about right now. The bottom line is that we want our customers to be able to choose the power solution that’s best for them.

As for zero carbon emissions, that’s a terrific goal but a very challenging one, as well. I know at Cummins, our approach will be to look for ways we can have the biggest impact possible on building a better world today, then accomplish them and then look for new ways we can make a difference.

Please discuss a recent product (or service) introduction(s) that you see as transformational for owner/operators of commercial ships and boats.ENHYDRA: Earlier we mentioned Enhydra, the large excursion boat now based in San Francisco. Some are calling the 600-seat vessel one of the “greenest” boats in America

It has a lithium-ion battery-electric hybrid propulsion system that can complete extended cruises completely on electricity. Each of the vessel’s two screws are connected to generators powered by 410-horsepower Cummins QSL9 diesel engines.

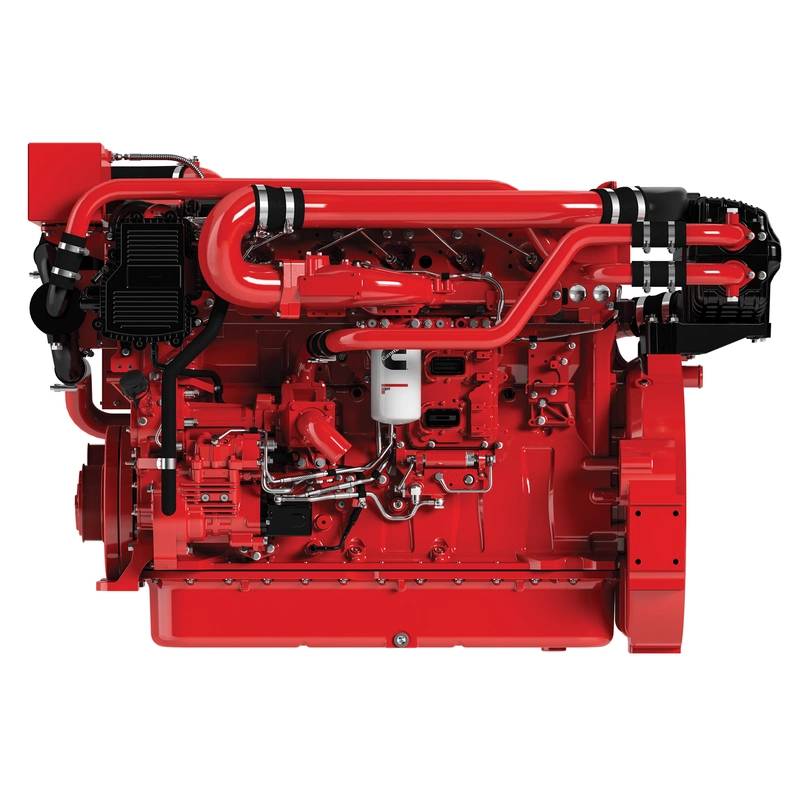

QSK95: In March of 2018, Cummins announced that Azam Marine had selected two QSK95 engines to power its next passenger ferry, the Kilimanjaro VII, which will operate between the islands of Zanzibar, Pemba and mainland Tanzania. The QSK95 is the largest engine diesel engine Cummins makes. The high-speed diesel engine offers a power output previously exclusive to much larger medium-speed marine engines with power ratings from 3,200 to 4,200 horsepower for propulsion, auxiliary, generator and diesel electric applications. The QSK95 has a lower capital cost, more compact installation and exceptional fuel efficiency when compared to other engines in its class, which translates into lower greenhouse gases.

THE X15: Also in 2018, Cummins announced that a version of its extremely popular X15 engine was available for commercial marine markets including inland waterways, commercial fishing and passenger transport. The engine has more power and durability than any other high-speed marine engine. The marine X15 is designed to withstand high hour, continuous duty operation, offering variable speed and fixed speed ratings between 450 horsepower (336 kW) and 600 horsepower (447 kW), while meeting EPA Tier 3 and IMO Tier II emission standards.

The Cummins Marine X15 engine.

The Cummins Marine X15 engine. -

- MN 100: Cummins, Inc. Marine News, Aug 2014 #10

500 Jackson Street Columbus, Indiana 47201 Tel: (812) 377-5000 Email: [email protected] Website: www.cummins.com Chairman/CEO: Tom Linebarger The Company: Global power leader Cummins, Inc. is a corporation of complementary business units that design, manufacture, distribute and service

-

- Cummins Announces Availability Of New XA' Series Diesel Engines Maritime Reporter, Feb 1988 #55

—Literature A v a i l a b l e— Cummins Engine Co., Inc., which acquired majority ownership of Onan Corporation in early 1986, recently announced an agreement with Hawker-Siddeley and Onan Corporation whereby Cummins will assume responsibility for the Onan L series diesel engines. Under this agreement

-

- MN100: Cummins Marine, Inc. Marine News, Aug 2016 #22

The Company: Cummins, Inc. is a corporation of complementary business units that design, manufacture, distribute and service engines and related technologies, including fuel systems, controls, air handling, filtration, emission solutions and electrical power generation systems. Cummins has also created a

-

- MN 100: Cummins Marine, Inc. Marine News, Aug 2015 #26

The Company: Global power leader Cummins, Inc. is a corporation of complementary business units that design, manufacture, distribute and service engines and related technologies, including fuel systems, controls, air handling, filtration, emission solutions and electrical power generation systems. Cummins

-

- Cummins Introduces First Of Its B And C Series Marine Models Maritime Reporter, Mar 15, 1985 #17

Cummins Engine Company recently introduced the first Marine models of its new B and C Series of lower horsepower diesels, which will expand Cummins Marine product line to 61 horsepower on the low end. The B Series propulsion engines will consist of four and six-cylinder models with displacement of 3.

-

- Desco Marine Launches Its 100th Cummins-Powered Boat Maritime Reporter, Jan 15, 1980 #9

the launching of the Singleton Fleets 56. The 73-foot vessel is the 2,200th wood shrimp boat built by Desco, and the 100th Desco boat powered by a Cummins K-series marine diesel engine. Paul Kahlenbeck, vice president- Industrial Marketing, Cummins Engine Co., commemorated the occasion by p r e

-

- Foss Seattle Shipyard Named Cummins Dealer For Parts And Service Maritime Reporter, Mar 15, 1981 #46

Foss Shipyard, Seattle, has been named a marine dealer for Cummins Northwest Industrial (CNI) and will provide service and spare parts throughout the Northwest. The agreement between Foss Launch & Tug Company and Cummins Northwest Industrial was recently announced by Ross Bishop, Commercial Marine

-

- Interview: Eddie Brown, Cummins' Director of Business Development, Marine Marine News, Jul 2020 #12

How do you see business today, and where is Cummins looking for opportunities as COVID-19 and volatile oil markets generate market uncertainty?Even in the current state, we are still seeing a solid level of interest and activity in the commercial marine space. Scheduling has been impacted and some areas

-

- Konrad, Cummins Propulsion Package Partnership Maritime Reporter, Nov 2013 #46

Sterndrive specialist Konrad Marine formally entered a partnership with diesel engine manufacturer Cummins Marine to jointly offer a complete propulsion package to the commercial, military and recreational maritime markets, a partnershipo announced October 9 at the Workboat Show in New Orleans. The package

-

- Cummins Inc. And CitiCapital Launch Alliance Maritime Reporter, Apr 2002 #46

Cummins Inc. and CitiCapital have reached an agreement to promote a cosponsored marine finance program. Under the agreement, customers who purchase Cummins engines for various commercial vessels will receive exclusive finance products provided by Citi- Capital. This agreement demonstrates the coopera

-

- New Emergency Genset from Cummins Maritime Reporter, Jul 2014 #51

Cummins launched the QSK60 C Power (CP) emergency generator set for offshore applications. It is driven by the QSK60 marine auxiliary engine with MCRS fuel system. Cummins emergency generator sets feature a Cummins marine auxiliary engine fit with radiator cooling and two independent starting systems.

-

)

February 2024 - Marine News page: 41

)

February 2024 - Marine News page: 41(AFD) located in Alameda County, Calif. According to the build- er, the new Moose M2-38 ? reboat is the most powerful ever assembled, running on twin Cummins turbo charged QSB 6.7L 480HP engines with Twin Disc Transmissions and Hamilton HJX 29 waterjets. The catamaran can reach speeds up to 38 knots

-

)

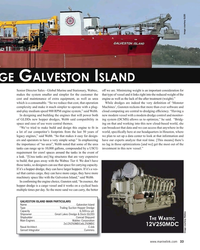

December 2023 - Maritime Reporter and Engineering News page: 33

)

December 2023 - Maritime Reporter and Engineering News page: 33Conrad Shipyard T W HE ABTEC Main Engines Wabtec Corporation 2x12V250MDCx6L250MDC 12V250MDC Naval Architect C-Job Genset Integrator Cummins Image courtesy Wabtec www.marinelink.com 33 MR #12 (18-33).indd 33 12/5/2023 12:39:26 P

-

)

December 2023 - Maritime Reporter and Engineering News page: 28

)

December 2023 - Maritime Reporter and Engineering News page: 28system. The marine diesel engines plus accessories pire State VII for SUNY Maritime; Patriot State for Massa- were delivered to Wabtec channel partner Cummins Sales & chusetts Maritime Academy; State of Maine for Maine Mari- Service, who in turn package the engines into marine gensets time Academy; Lone

-

)

November 2023 - Marine News page: 55

)

November 2023 - Marine News page: 55support evolving tures two electric motors, lithium-ion batteries and two scienti? c and teaching needs. A ? rst-of-its-kind electric 306-horsepower Cummins diesel generators. For added winch, designed by engineers at the Woods Hole Oceano- ef? ciency, the vessel boasts a custom catamaran hull con- graphic

-

)

November 2023 - Marine News page: 45

)

November 2023 - Marine News page: 45of 20 x 16V250MDC Wabtec EPA T4 marine diesel 2021, followed by the ? fth and ? nal vessel in 2022. engines plus accessories to its channel partner, Cummins The government sponsored shipbuilding program is the Sales & Service, who has the job of packaging the engines U.S.’ ? rst to utilize the VCM

-

)

September 2023 - Maritime Reporter and Engineering News page: 30

)

September 2023 - Maritime Reporter and Engineering News page: 30Tier 4 The marine diesel engines plus accessories were delivered to emissions regulations, which reduces engine NOx emissions by Wabtec channel partner Cummins Sales & Service, who in turn 76% over previous engine models, without the use of costly af- packaged the engines into marine gensets for the ? ve

-

)

September 2023 - Maritime Reporter and Engineering News page: 27

)

September 2023 - Maritime Reporter and Engineering News page: 27. For the NSMV se- ries, Wabtec will deliver a total of 20 x 16V250MDC Wabtec EPA T4 marine diesel engines plus accessories to its channel partner, Cummins Sales & Service, who has the job of pack- aging the engines into marine gensets for the ? ve vessels. Getting schooled on the new system is a process

-

)

April 2023 - Maritime Reporter and Engineering News page: 19

)

April 2023 - Maritime Reporter and Engineering News page: 19and generators) tug to Seab- emissions in a particular circumstance. ulk Towing, with a design from Robert Allan Ltd. The message from Bomgardner and Cummins was that ac- The vessel, Spartan, which can operate using the Tier 4 tual readings, rather than formula-based estimates, are key for main engines

-

)

April 2023 - Maritime Reporter and Engineering News page: 18

)

April 2023 - Maritime Reporter and Engineering News page: 18autumn 2022 conference, reiterated the need for actual mea- surement of emissions, rather than approximations, in opti- mization. Fellow panelist, David Cummins (President and eWolf tug refueling at Corvus shoreside charging station. Images courtesy Corvus 18 Maritime Reporter & Engineering News • April

-

)

April 2023 - Marine News page: 40

)

April 2023 - Marine News page: 40. The vessel’s lightship weight is 160,000 pounds so it can be hauled with the Fire Island Ferries’ existing lift. The ferry is powered by twin Cummins QSL9 Tier 3 marine engines with ZF Marine CruiseCommand control system and Twin Disc transmissions. Electrical power is provided by a Cummins Onan

-

)

February 2023 - Marine News page: 31

)

February 2023 - Marine News page: 31movement towards digitalization and more auto- yards in southern New Jersey. The aluminum catamaran mated operations. style ferries are powered by twin Cummins 2300 hp en- Along the East Coast, Casco Bay Line (serving islands in gines and ZF transmissions. Nearby operator Seastreak, coastal Maine, out of

-

)

February 2023 - Marine News page: 9

)

February 2023 - Marine News page: 9you need?’ Because you need to think of it different than if you say, ‘Okay, I’ve got a towboat, it needs 2,000 horsepower. I usually buy two Cat or two Cummins en- gines, and that’s what I want to emulate.’ Back up. Because how much power do you actually need?” “With Hydrogen One, we initially thought we

-

)

December 2022 - Maritime Reporter and Engineering News page: 36

)

December 2022 - Maritime Reporter and Engineering News page: 36is needed due to life cycles. Accurate monitoring Make .....................................................................Chongqing Cummins Engine Co., Ltd and control of the energy can be achieved as the supercapaci- Model .............................................................

-

)

December 2022 - Maritime Reporter and Engineering News page: 31

)

December 2022 - Maritime Reporter and Engineering News page: 31........46,080 kW with numerous cost and time-saving opportunities, especially Emergency power ............................................................Cummins CSMXTA60OLGS when drilling programs and well con? gurations require the Power dist. ........................................ 3x Siemens 11KV AC

-

)

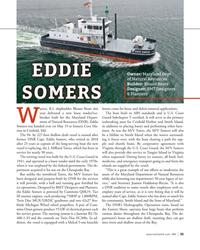

November 2022 - Marine News page: 55

)

November 2022 - Marine News page: 55is also ice operations. Designed by BMT Designers and Planners, a DNR tradition to name vessels after employees with ex- the Eddie Somers is powered by Cummins QSK19, Tier emplary years of service, so it is very ? tting that it will be III marine engines, each producing 750HP at 1,800RPM, named after Capt

-

)

August 2022 - Maritime Reporter and Engineering News page: 56

)

August 2022 - Maritime Reporter and Engineering News page: 56aluminum crew Pilot boats are all weather boats, de- boats grew to 125-ft. vessels powered by signed for sea keeping and speed. The up to ? ve 700 hp Cummins KTA19 en- new boat, Aransas Pilot III, is all of that. gines, then, the boats grew to 145 by 28- The hull design gives her excellent han- ft. with

-

)

July 2022 - Marine News page: 34

)

July 2022 - Marine News page: 34concerns. One example: that a release alum. The power package is comprised of 360 kW of of unignited hydrogen might be sucked into a tug’s inte- Cummins fuel cells and Hexagon hydrogen storage tanks rior spaces, while the tug was adjacent to the generator, or with a capacity of 246 kg. This system

-

)

July 2022 - Marine News page: 32

)

July 2022 - Marine News page: 32limitless drogen fuel cell (FC) generator was built by Hydrogenics, supply of a fuel that, according to many experts, shares a company now owned by Cummins, Inc. Young Brothers, characteristics with natural gas, making H a relatively fa- the Hawaiian shipping company, agreed to use the genera- miliar

-

)

April 2022 - Marine News page: 43

)

April 2022 - Marine News page: 43Products Cummins 2 1 In-Mar Solutions 4 Intellian 3 ARMACH Sea Machines 5 vessels. This follows on from the multi- 1. In-Mar Solutions: 3. Hull Cleaning as a Service Wynn Marine Type C Greensea Systems has launched spin- year agreement that was signed in Oc- & Type D, Heavy Duty off Armach

-

)

April 2022 - Marine News page: 40

)

April 2022 - Marine News page: 40the new ferry will provide transport between Bay Shore, New York and various ports along the Great South Bay of Fire Island. It will be powered by twin Cummins QSL9 Tier 3 marine engines with ZF Marine CruiseCommand control Elliott Bay Design Group system and transmissions. Electrical power shall be pro- vided

-

)

March 2022 - Marine News page: 28

)

March 2022 - Marine News page: 28. The private sector will then be in a better position to mo- “We need to be working now, with urgency, in all three bilize with ? nancing.” areas,” Cummins commented. 2030 to 2050 are popularly With eWolf, cost and ? nancing details have not been viewed as the expected window for engine/fuel transitions

-

)

February 2022 - Maritime Reporter and Engineering News page: 52

)

February 2022 - Maritime Reporter and Engineering News page: 52company added. house. When crab ? shing, the clear, aft deck will be capable of carrying up to 150 collaps- ible, 100-pound crab pots. Photo courtesy Cummins When rigged for trawling, a gantry will be mounted over with a proven SCR catalyst. The transmission the stern with two net drums. A pair to trawl

-

)

November 2021 - Marine News page: 62

)

November 2021 - Marine News page: 62by two to four crew members, minum catamaran equipped with quad 799-horsepower Atlantic Endeavor has capacity to transport up to 24 wind MAN engines, Cummins generators, ZF Transmissions, farm technicians. 62 | MN November 202

-

)

November 2021 - Marine News page: 60

)

November 2021 - Marine News page: 60TOP BOATS 2021 Metal Shark FIRE BOAT 2 A “NEXT-GENERATION” FIREBOAT powered by twin 550-HP Cummins QSB 6.7 inboard die- sels mated to Hamilton HTX30 waterjets with Blue Arrow control system via Twin Disc MG 5065 SC transmissions. Fire Boat 2, delivered to Orange Beach Fire Rescue in Ala- This con?