Machine Vision

-

- MTR100: #4 Martin McDonald , SVP, Oceaneering Marine Technology, Jun 2019 #18

Martin McDonald , SVP, Oceaneering ... Directing the world’s largest fleet of work class ROVs.

The editors of Marine Technology Reporter are pleased to share that Martin McDonald, Oceaneering, is #4 in the 14th Annual "MTR100". The full electronic edition of Marine Technology Reporter is available at https://magazines.marinelink.com/nwm/MarineTechnology/201907/.

Oceaneering is a pioneer and leader in the world of subsea robotics, and a ‘by the numbers’ look at the company provides a staggering view. Oceaneering operates a fleet of 275 work class ROVs – the world’s largest– as well as 60 observation class ROVs. The ROV division has approximately 2,400 full-time personnel, with about 2,000 of these people in the field. And with ROVs diving daily it conducts more than 100,000 missions in a year. While the numbers are impressive, Oceaneering is not immune to the prolonged downturn in the offshore energy sector, and it has retired units that have come to the end of their working life, trimming the ROV fleet from its peak of 318 work class ROVs in 2014.

With its leadership, Oceaneering has been and remains a driving force in the technological and capability development of ROVs. “We’ve identified some gaps in the market. As we move forward, autonomy, remote operations, speed, and reliability are all coming into play,” said McDonald. “We see more remote and autonomous operations taking place that are in line with the industry focus of reducing risk to personnel and lowering carbon emissions with fewer assets at the worksite.Additionally, there is a need for more specialized equipment. Today, ROVs are working in deeper waters on increasingly complex work scopes and also in harsh shallow-water environments with high-current, low-visibility areas, so it is essential to have higher-powered units with high-specification and reliable intervention capabilities that are able to work efficiently through the full range of environmental conditions in the frontier oil and gas, and renewables sectors.”

Specifically, the company has a team dedicated and specializing in technology and new product development that is working on the next generation of vehicles, which will encompass residency, robotic, and autonomous functions, according to McDonald. “We’re developing this technology at an advanced stage now, and we expect to be trialing one of our next-generation vehicles in Q3 2019.”

Significantly, the company conducted a demonstration of remote operations and autonomous docking in the Gulf of Mexico, where it remotely piloted an ROV, which was stationed on board a drilling rig, from its operations center in Houston while also performing autonomous docking functions. “Remote piloting technology is maturing and is currently operational in the North Sea, where we have a number of contracts. We’re piloting ROVs remotely from our mission support center in Stavanger, Norway. This center has enabled us to complement ROV operations offshore with onshore operations,” said McDonald.

When McDonald and his team look at emerging technology trends, they see software and control systems technology – which go hand-in-hand – as the most pivotal to move the market forward faster.

“They allow us to optimize the ROV power management systems, along with navigation, station keeping, manipulator tasks, sensors, intervention tooling, and system diagnostics, which leads to improved performance and efficiency gains. Continued software and control systems development are key components to enable subsea residency and autonomous interventions.”

But he noted that machine learning and machine vision are important, too. “We have been working on automated operations, such as auto docking, where the ROV pilot can direct the ROV to move autonomously to a docking point by moving a cursor on the screen, without any intervention on the joystick. It is the machine vision recognition software tied into the control and inertial navigation systems that allows it to perform those tasks consistently. This is still an emerging technology, and it takes a little time to dock autonomously. Finally, he notes that the telemetry, control systems, and communication links for ROVs have come a long way, too.

Last, but certainly not least, McDonald points to the development of Oceaneering’s “Empowered ROV” – or E-ROV – as an indicator of its view on the future of subsea robotics. “E-ROV is a resident, battery-powered ROV that will go subsea with a surface buoy. It’s a work class electric vehicle with a hydraulic power pack to support its manipulator functions, and it is controlled remotely from our onshore mission support center with communications via the 4G broadband network, using a self-deployed surface buoy,” said McDonald. “We believe (E-ROV) is a significant technological advancement to the next stage of subsea ROV residency. Our next generation of vehicle (the Freedom ROV) will be supported by a docking station at seabed and will have a hybrid functionality that will enable it to operate in two modes: remotely piloted via tether to provide real-time control – or operated in an autonomous and tetherless mode, using battery power.”

To read the full interview with Martin McDonald, visit:

www.marinetechnologynews.com/news/martin-mcdonald-division-oceaneering-587529 -

- ROVs: Time for Renewal in the Work Class world? Marine Technology, May 2021 #26

. Part of this is about automation. On Gemini, tool acquisition is no longer a manual piloting task, it’s an automated manipulator task, using machine vision and force accommodation, Steve Cohen, Vice President of Product Development at Schilling Robotics in TechnipFMC, told the Underwater Technology

-

- Subsea Technology and the New Routes to Residency Marine Technology, Jul 2020 #38

, the manipulator tip is a stab that picks up a tool and provides a hydraulic, electric and communications interface. The vehicle also has up to five machine vision cameras, so the vehicle knows what it’s looking at and can more accurately measure distance; the machine vision cameras help fine-tune station

-

- One-on-One with Martin McDonald, SVP, ROV Division, Oceaneering Marine Technology, Feb 2019 #34

software and control systems development are key components to enable subsea residency and autonomous interventions.There’s also machine learning and machine vision. As I mentioned earlier, we have been working on automated operations, such as auto docking, where the ROV pilot can direct the ROV to move autonomously

-

- Atlantic Canada Profiles: SubC Imaging Marine Technology, Jan 2017 #41

. SubC also currently has two products under late stage development and soon to be available for field testing. The first, the Rayfin Autonomous Machine Vision System, is designed for use on all platforms with special attention paid to the unique requirements of autonomous underwater vehicles (AUVs) which

-

- Tech File: A Resident Eyeball ROV Marine Technology, May 2021 #54

artificial intelligence onboard enables the ARV-i to optimize movements within its environment."Craig says the vehicle has an array of up to six machine vision cameras and one live 4K navigation camera, and it can deliver 17,000 lumens of lighting for high quality observation underwater. The vehicle weighs

-

- Subsea Robots in the Splash Zone Marine Technology, Jan 2020 #46

a handheld tool for divers — is affixed a probe carried by the robot and allowing it to trace subsea structures. It’s delivered by VAT. Using machine vision and automated thrusts in six directions, the tool follows a weld right around a structure, staying just millimeters form item being studied. When

-

- Good Undersea Vehicles Come in Small Packages Marine Technology, Jan 2020 #34

was designed by engineers at Queensland University of Technology (QUT) in Brisbane, Australia. The team at QUT work in a robotics center focused on machine vision. They also work to support environmental assessments on the Great Barrier Reef. A key paradigm shift was enabled when the team, recognizing that

-

- Ocean Autonomy: Norway to the Fore Marine Technology, Apr 2018 #24

the body of an underwater vehicle, in order to compensate for or reduce drag, says Sørensen. He also cites micro to macro actuation and sensing, and machine vision systems using hyperspectral sensing which can take in any wavelength to classify and detect things that we haven’t been able to before. The possibilitie

-

- MTR100: The Ones to Watch Marine Technology, Jul 2018 #34

learning to electronic and robotics engineering.Forrsea is designing, building and qualifying a new autonomous ROV called ATOLL. It is designed to use machine vision technology to dock on subsea infrastructure. Because vision-based technology is critical to the autonomous docking of ATOLL, Forssea has developed

-

- Subsea Vehicles: A Journey to the Under – and Outer – Worlds Marine Technology, Jan 2022 #34

seafloor maps to centimeter or even millimeter scale. So we’re super excited about this.”TRN can be done with a small cheap camera – machine vision cameras are in the order of $1700, says Machado. While it’s not a complete navigation solution – some acoustics will be needed to give

-

- Maritime Autonomy: The Reality Maritime Reporter, Apr 2019 #28

and from customer feedback,” said Johnson. “We are also deep into the advancement of vessel perception technology, namely long-range machine vision which utilizes large data sets and A.I. to “see” and interpret the domain around an operating vessel by identifying, classifying, and

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36thrusters. A second identical set of batteries is located on the port side of the vehicle. Individual battery packs are held in separate pockets machined into the ISOFloat syntactic. Used with Permission, Earthship LLC. 36 March/April 2024 MTR #3 (34-47).indd 36 4/4/2024 10:51:34 A

-

)

March 2024 - Marine Technology Reporter page: 32

)

March 2024 - Marine Technology Reporter page: 32and buoyant syntactic foam. The collec- tion plan on nodules by March 2024. tion vehicle uses sonar to identify the position of the nodules UK-based Soil Machine Dynamics (SMD) designed, devel- and has attained collection ef? ciency rates of at least 97% in oped and delivered the mining machinery planned

-

)

April 2024 - Maritime Reporter and Engineering News page: 41

)

April 2024 - Maritime Reporter and Engineering News page: 41. We see demand continuing to grow into the system so watchkeepers can from both domestic and international more easily assess the options they have Machine Vision shipowners, and we are also seeing in- for responding to challenging situations. Groke Pro is the ? rst machine vision terest from insurance

-

)

April 2024 - Maritime Reporter and Engineering News page: 40

)

April 2024 - Maritime Reporter and Engineering News page: 40TECH FEATURE SITUATIONAL AWARENESS SITUATIONAL AWARENESS SYSTEM BATTLES COGNITIVE FATIGUE IN WATCHKEEPERS All images courtesy Groke Technologies Today’s evolving maritime security risks pose all-too-familiar threats to international shipping, and as just one of the many causes of fatigue, they add

-

)

April 2024 - Marine News page: 39

)

April 2024 - Marine News page: 39to popular expe- tions: Should the steel be processed in- importance of thoughtful process- rience and opinion, modern solutions house with a wheel machine for primer design in minimizing traditional bot- do exist to the historically chaotic application, or is it more ef? cient to tlenecks. The ef

-

)

April 2024 - Marine News page: 37

)

April 2024 - Marine News page: 37Feature Electric Tugs could change down the road. “What do we really need an In San Diego, eWolf’s transits will typically run 20-30 engineer to do? There are no moving parts. So, how does minutes, “not the optimal operation to really see a lot of that [role] change? How does that change where we work?

-

)

April 2024 - Marine News page: 15

)

April 2024 - Marine News page: 15Q&A time, sometimes we win in game seven, but it really takes now to make sure that folks understand that tug and barge a united industry, and so I just really appreciate the great transportation is the most sustainable mode of freight work of AWO members, of coalition partners, shippers, transportation?

-

)

February 2024 - Maritime Reporter and Engineering News page: 44

)

February 2024 - Maritime Reporter and Engineering News page: 44Tech Files Latest Products & Technologies MarineShaft Yanmar Hydrogen MarineShaft specializes in urgent re- Fuel Cell AIP pair/replacement of damaged rudder and Yanmar Power Technology Co., Ltd. propeller equipment along with many (Yanmar PT), a subsidiary of Yanmar on-site repair services. MarineShaft

-

)

February 2024 - Maritime Reporter and Engineering News page: 37

)

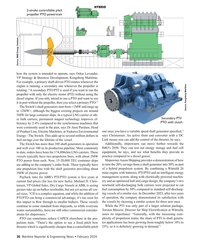

February 2024 - Maritime Reporter and Engineering News page: 37PTI/PTO "In a typical LNG carrier, permanent magnet technology improves ef? ciency by 2-4% compared to synchronous machines." – Dr. Jussi Puranen, Head of Product Line, Electric Machines, at Yaskawa Environmental Energy / The Switch The Switch’s shaft generators start from <1MW and range up to 12MW+.

-

)

February 2024 - Maritime Reporter and Engineering News page: 36

)

February 2024 - Maritime Reporter and Engineering News page: 36LNG carrier or oth- Secondary PTI/ er bulk carriers, permanent magnet technology improves ef- PTO with clutch ? ciency by 2-4% compared to the synchronous machines that were commonly used in the past, says Dr Jussi Puranen, Head of Product Line, Electric Machines, at Yaskawa Environmental one once you have

-

)

February 2024 - Marine News page: 35

)

February 2024 - Marine News page: 35the years, Virtual Marine has witnessed signi? cant advancements in technology, particularly in virtual reality, graphics processing power and machine learning. Burry highlighted the pivotal role of machine learning in shap- “We enable workers to develop ing the future of training. By analyzing

-

)

February 2024 - Marine News page: 34

)

February 2024 - Marine News page: 34Feature Marine Simulation All images courtesy Virtual Marine S T R DIMULATOR RAINING IS THE EAL EAL By Eric Haun A legacy of innovation n the commercial maritime and offshore industries, where worker safety and competency are crucial, ef- Virtual Marine’s journey began two decades ago with a sin- fect

-

)

February 2024 - Marine News page: 21

)

February 2024 - Marine News page: 21commitment is in the Indiana”, an engine “made by the United States Electrical, development of marine terminals to support offshore wind Radio and Machine Workers in Pittsburgh”, and American construction and operation. As previously reported, the mariners from Seafarers International Union. Maritime

-

)

February 2024 - Marine News page: 19

)

February 2024 - Marine News page: 19when forming their own opinions or making decisions. their job. The current boom in “consumable AI” has started to change how we think about PPE and machine-mounted safety technology. In 2024, ensure that all your workers have access to the necessary safety equipment and are trained to use them correctly

-

)

January 2024 - Marine Technology Reporter page: 59

)

January 2024 - Marine Technology Reporter page: 59, ports, aquaculture and subsea. at Oi24 include: Oi’s focus in 2024 will re? ect the global challenges con- • Cathx Ocean, combining sensor data, machine vision fronting the industry and in? uencing the trajectory of tech- and machine learning based automation to deliver information nology development

-

)

January 2024 - Marine Technology Reporter page: 52

)

January 2024 - Marine Technology Reporter page: 52TECH FEATURE BATTERY SAFETY Images courtesy Engineered Fluids Inc. This experiment has since been replicated with other batteries and cell con? gurations, and demonstrates the inherent ? re safety of SLIC Technology. jacent cells were not affected, and continued to operate nor- Failures) of electronic

-

)

January 2024 - Marine Technology Reporter page: 44

)

January 2024 - Marine Technology Reporter page: 44ROVS ture, port security monitoring and various marine research operations. Likewise, the Voyis Discovery Stereo Camera is a widely applicable piece of technology offering high level clarity and precision in visual captures of underwater envi- ronments and immediate creation of real-time 3D models.

-

)

January 2024 - Marine Technology Reporter page: 43

)

January 2024 - Marine Technology Reporter page: 43. • Advancements in Automation and Autonomy: Au- tonomous and semi-autonomous work class ROV tech- AI will also improve imaging and data analysis using machine nology has developed signi? cantly in recent years. These learning algorithms to process and analyze images and sensor systems have advanced computer

-

)

January 2024 - Marine Technology Reporter page: 32

)

January 2024 - Marine Technology Reporter page: 32SUBSEA VEHICLES DEFENSE USS Baltimore (SSN 704) served for just 15 and a half years in 2004, and the newest, USS Hyman G. Rickover (SSN 795) of active service. joining the ? eet in October of 2023. Newer versions will be Los Angeles-class submarines carried MK-48 heavyweight ? tted with the Virginia

-

)

January 2024 - Marine Technology Reporter page: 20

)

January 2024 - Marine Technology Reporter page: 20with a wind farm. And there is a substantial Let’s look at the Blue Star technology today. Can you discuss CO2 savings. So with one of our small machines, we estimate where it’s at in its development cycle and what’s your time- that we can save as much CO2 as a machine that generates 10 line for

-

)

January 2024 - Marine Technology Reporter page: 19

)

January 2024 - Marine Technology Reporter page: 19big storms somewhat nuanced and complex hydrodynamic things, but this past year, we have some great videos on YouTube from basically they cause the machine to move a lot more in waves. cameras on the machine. The front of the machine has this big And if you move more in waves, you generate more power

-

)

January 2024 - Marine Technology Reporter page: 18

)

January 2024 - Marine Technology Reporter page: 18software for naval archi- brought to the table is innovations around the shape of the tecture applications, and I ran with that and earned a Master’s machine. Our prototype has these big scoops on the front and 18 January/February 2024 MTR #1 (18-33).indd 18 1/30/2024 6:52:05 P

-

)

January 2024 - Maritime Reporter and Engineering News page: 38

)

January 2024 - Maritime Reporter and Engineering News page: 38of marine vessels and offshore units including in shorter ? ve- or 10-year intervals, depending on the owner. galleys, provision stores, refrigeration machinery, laundries, Wendelin said ALMACO also strives to maximize utiliza- public spaces, as well as guest cabins and crew living quarters. tion of advanced

-

)

January 2024 - Maritime Reporter and Engineering News page: 28

)

January 2024 - Maritime Reporter and Engineering News page: 28MEET THE CTO emission target. “We decided it’s better to have 3 vessels with dual For the largest ships in the CMB fuel than to have one zero-emission vessel [with ? eet, the focus is on ammonia, as it is no market]. [A zero-emission vessel is] often a cheapest from a production point of white elephant