Page 12: of Marine Technology Magazine (April 2005)

Read this page in Pdf, Flash or Html5 edition of April 2005 Marine Technology Magazine

12 MTR April 2009

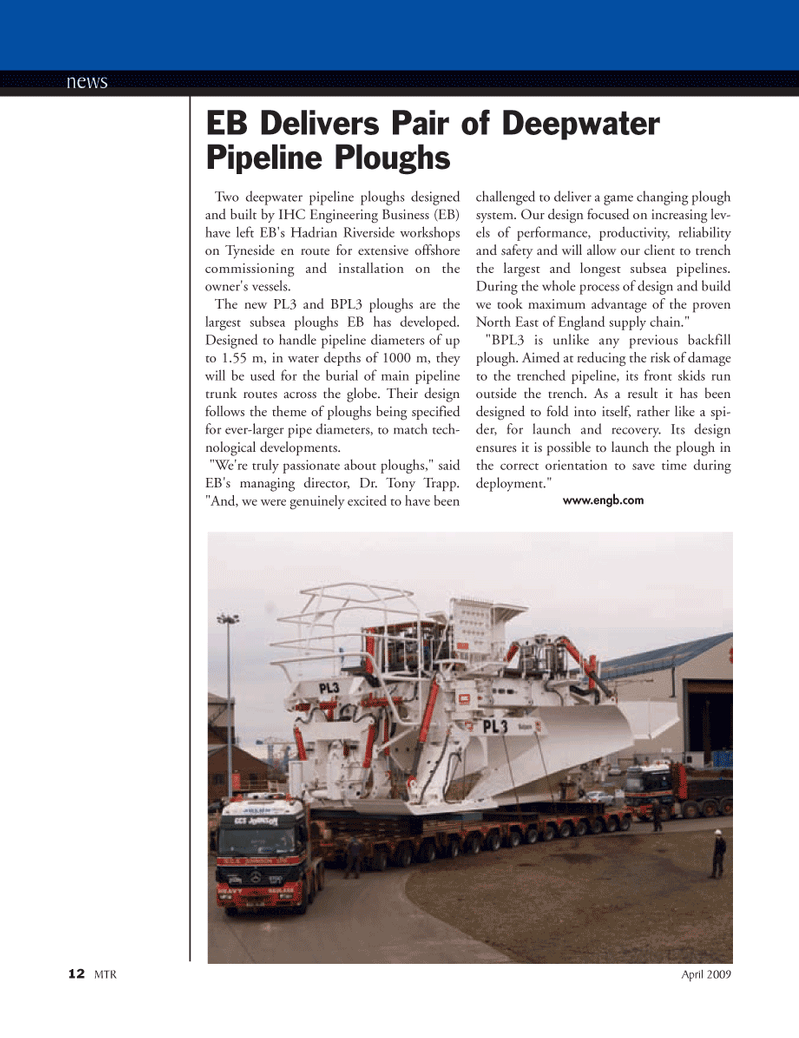

Two deepwater pipeline ploughs designed and built by IHC Engineering Business (EB) have left EB's Hadrian Riverside workshops on Tyneside en route for extensive offshore commissioning and installation on the owner's vessels.

The new PL3 and BPL3 ploughs are the largest subsea ploughs EB has developed.

Designed to handle pipeline diameters of up to 1.55 m, in water depths of 1000 m, they will be used for the burial of main pipeline trunk routes across the globe. Their design follows the theme of ploughs being specified for ever-larger pipe diameters, to match tech- nological developments. "We're truly passionate about ploughs," said

EB's managing director, Dr. Tony Trapp. "And, we were genuinely excited to have been challenged to deliver a game changing plough system. Our design focused on increasing lev- els of performance, productivity, reliability and safety and will allow our client to trench the largest and longest subsea pipelines.

During the whole process of design and build we took maximum advantage of the proven

North East of England supply chain." "BPL3 is unlike any previous backfill plough. Aimed at reducing the risk of damage to the trenched pipeline, its front skids run outside the trench. As a result it has been designed to fold into itself, rather like a spi- der, for launch and recovery. Its design ensures it is possible to launch the plough in the correct orientation to save time during deployment." www.engb.com news

EB Delivers Pair of Deepwater

Pipeline Ploughs

MTR#3 (1-17).qxd 3/27/2009 1:47 PM Page 14

11

11

13

13