Page 40: of Marine Technology Magazine (April 2006)

The Offshore Technology Edition

Read this page in Pdf, Flash or Html5 edition of April 2006 Marine Technology Magazine

While one of the missions of Chikyu — to tap and study the earth's mantle — is revolutionary, it relies on equipment proven in other offshore industries to help it achieve this end. It is equipped with the Riser drilling sys- tem that has achieved success in oceanic oil drilling, and is designed to shield the vessel against eruptions of methane gas and pressurized fluids, while allowing for the retrieval of valuable core samples.

In addition, the vessel's Dynamic Positioning System (DPS) is designed to keep the vessel on position, counter- acting the drift from wind, waves and sea current. The 210 m, 57,000 ton ship can efficiently remain on station using its GPS and six azimuth thrusters.

There are four integrated research areas on the vessel that house multiple research facilities for physical, scien- tific, and biological analysis by using the sampled core (cylindrical sediment and/or rock sample) and the drilled hole.

Drilling floor and Machines

Drilling machines are located in a way that allows an efficient and safe drilling operation on the drilling floor.

The pipes for drilling, such as casing, riser, and drill pipes, that are stored on the pipe rack at the front end and of the vessel, are lifted by deck cranes and loaded onto the pipe transfer system.

This pipe transfer system transfers the pipes to the drill floor on rails mounted on the drilling floor. The trans- ferred pipes are assembled, connected, and run down into the sea floor by the drilling machines on the drilling floor.

For this operation, there are different machines to manage each task. The main machines are: Hydraracker, to move drill pipes on the drill floor; Roughneck, to connect drill pipes; Top Drive, to rotate pipes for drilling; and

Drawworks, to lift drill pipes and Top Drive.

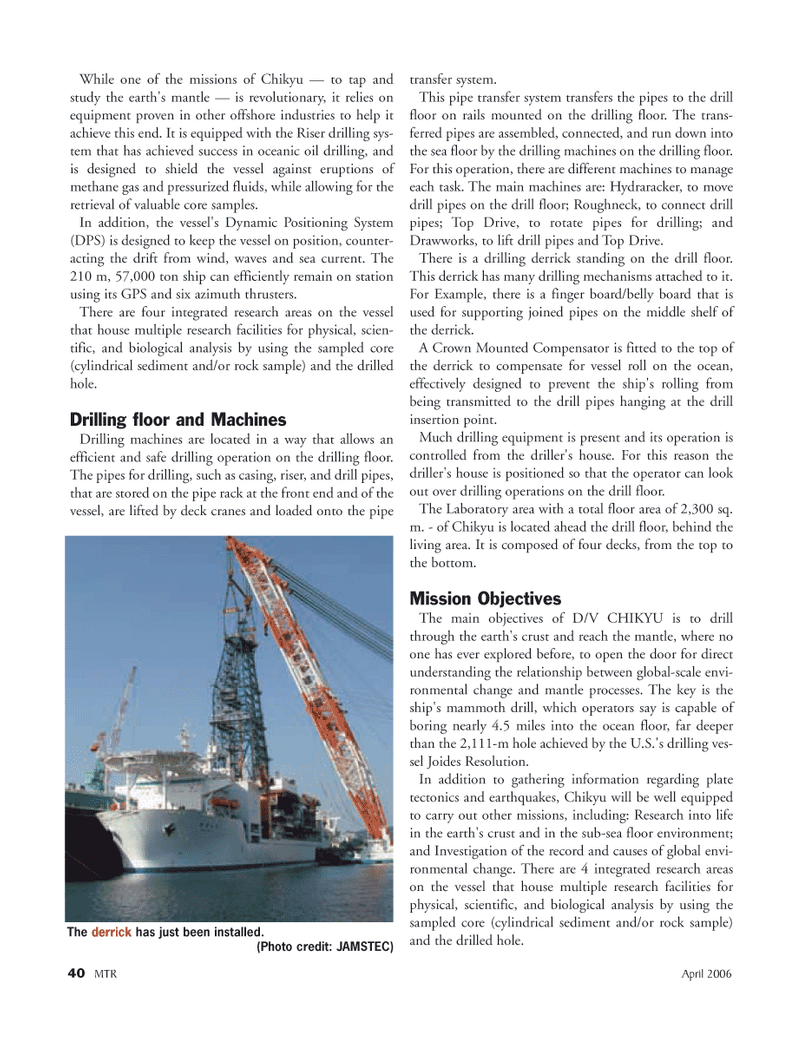

There is a drilling derrick standing on the drill floor.

This derrick has many drilling mechanisms attached to it.

For Example, there is a finger board/belly board that is used for supporting joined pipes on the middle shelf of the derrick.

A Crown Mounted Compensator is fitted to the top of the derrick to compensate for vessel roll on the ocean, effectively designed to prevent the ship's rolling from being transmitted to the drill pipes hanging at the drill insertion point.

Much drilling equipment is present and its operation is controlled from the driller's house. For this reason the driller's house is positioned so that the operator can look out over drilling operations on the drill floor.

The Laboratory area with a total floor area of 2,300 sq. m. - of Chikyu is located ahead the drill floor, behind the living area. It is composed of four decks, from the top to the bottom.

Mission Objectives

The main objectives of D/V CHIKYU is to drill through the earth's crust and reach the mantle, where no one has ever explored before, to open the door for direct understanding the relationship between global-scale envi- ronmental change and mantle processes. The key is the ship's mammoth drill, which operators say is capable of boring nearly 4.5 miles into the ocean floor, far deeper than the 2,111-m hole achieved by the U.S.'s drilling ves- sel Joides Resolution.

In addition to gathering information regarding plate tectonics and earthquakes, Chikyu will be well equipped to carry out other missions, including: Research into life in the earth's crust and in the sub-sea floor environment; and Investigation of the record and causes of global envi- ronmental change. There are 4 integrated research areas on the vessel that house multiple research facilities for physical, scientific, and biological analysis by using the sampled core (cylindrical sediment and/or rock sample) and the drilled hole.

The derrick has just been installed. (Photo credit: JAMSTEC) 40 MTR April 2006

MTR#3 (33-48).qxd 4/7/2006 11:22 AM Page 40

39

39

41

41