Page 31: of Marine Technology Magazine (January 2007)

Seafloor Engineering

Read this page in Pdf, Flash or Html5 edition of January 2007 Marine Technology Magazine

www.seadiscovery.com Marine Technology Reporter 31 incidents of unexploded ordnance being discovered in the vicinity of offshore platforms or pipe-laying operations.

Historically, each of these incidents impacted upon the project and posed obvious human and commercial risks.

Initial consultancy resulted in the delivery of bespoke training to key Shell employees, including offshore instal- lation managers, emergency response managers, logistics, safety and operational staff. This training is complement- ed by the provision of supporting protocols and docu- mentation. As training was delivered, it immediately pro- vided benefits by raising awareness and highlighting areas of incident control and response that could be enhanced in terms of both management and resources.

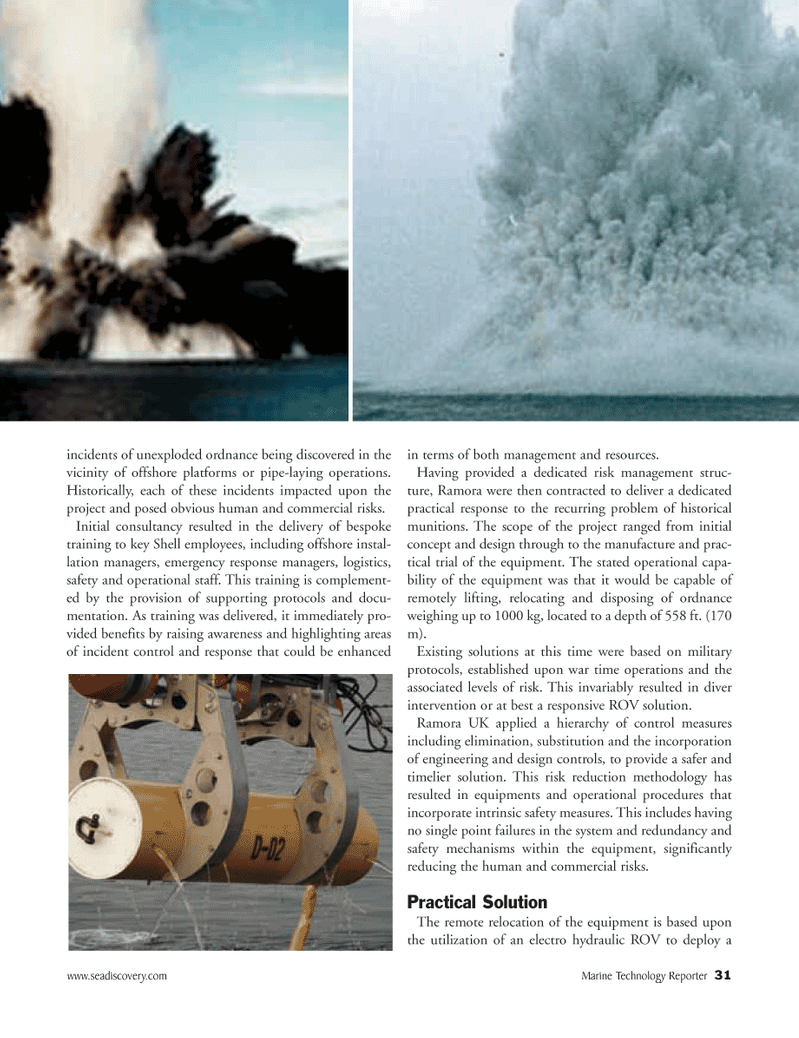

Having provided a dedicated risk management struc- ture, Ramora were then contracted to deliver a dedicated practical response to the recurring problem of historical munitions. The scope of the project ranged from initial concept and design through to the manufacture and prac- tical trial of the equipment. The stated operational capa- bility of the equipment was that it would be capable of remotely lifting, relocating and disposing of ordnance weighing up to 1000 kg, located to a depth of 558 ft. (170 m).

Existing solutions at this time were based on military protocols, established upon war time operations and the associated levels of risk. This invariably resulted in diver intervention or at best a responsive ROV solution.

Ramora UK applied a hierarchy of control measures including elimination, substitution and the incorporation of engineering and design controls, to provide a safer and timelier solution. This risk reduction methodology has resulted in equipments and operational procedures that incorporate intrinsic safety measures. This includes having no single point failures in the system and redundancy and safety mechanisms within the equipment, significantly reducing the human and commercial risks.

Practical Solution

The remote relocation of the equipment is based upon the utilization of an electro hydraulic ROV to deploy a

MTR#1 (17-32).qxd 1/11/2007 4:10 PM Page 31

30

30

32

32