Page 32: of Marine Technology Magazine (November 2010)

Fresh Water Monitoring and Sensors(lakes, rivers, reservoirs)

Read this page in Pdf, Flash or Html5 edition of November 2010 Marine Technology Magazine

32 MTR November/December 2010

Sonardyne

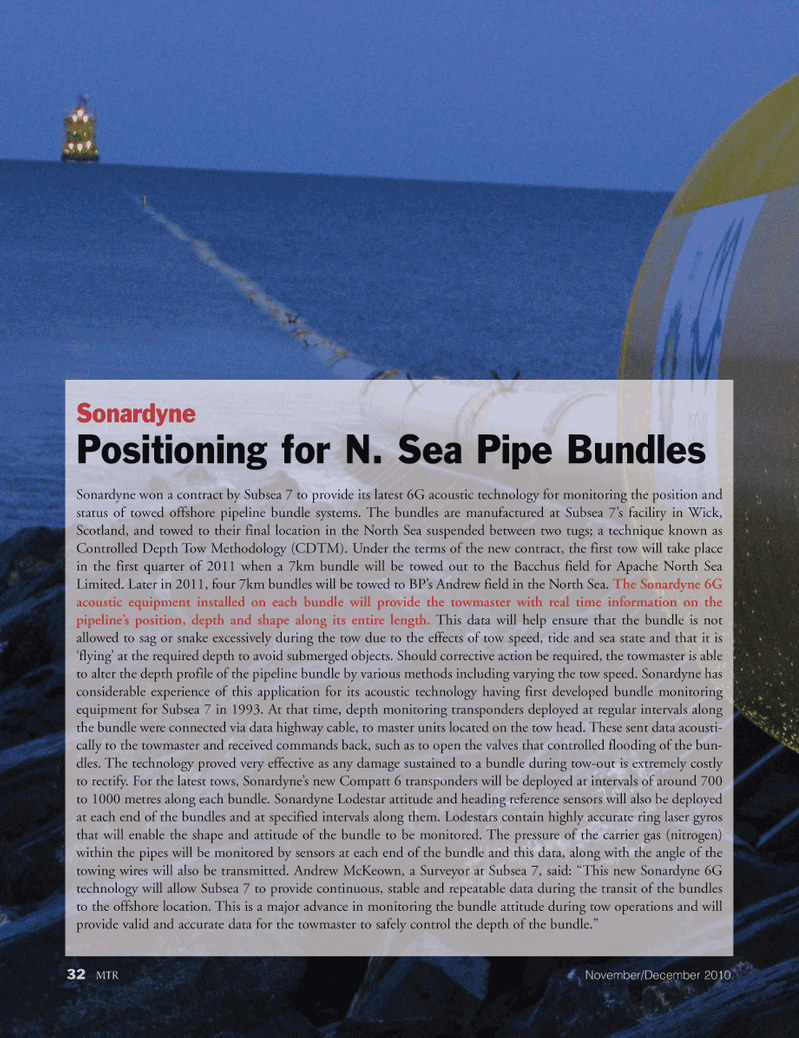

Positioning for N. Sea Pipe Bundles

Sonardyne won a contract by Subsea 7 to provide its latest 6G acoustic technology for monitoring the position and status of towed offshore pipeline bundle systems. The bundles are manufactured at Subsea 7’s facility in Wick,

Scotland, and towed to their final location in the North Sea suspended between two tugs; a technique known as

Controlled Depth Tow Methodology (CDTM). Under the terms of the new contract, the first tow will take place in the first quarter of 2011 when a 7km bundle will be towed out to the Bacchus field for Apache North Sea

Limited. Later in 2011, four 7km bundles will be towed to BP’s Andrew field in the North Sea. The Sonardyne 6G acoustic equipment installed on each bundle will provide the towmaster with real time information on the pipeline’s position, depth and shape along its entire length. This data will help ensure that the bundle is not allowed to sag or snake excessively during the tow due to the effects of tow speed, tide and sea state and that it is ‘flying’ at the required depth to avoid submerged objects. Should corrective action be required, the towmaster is able to alter the depth profile of the pipeline bundle by various methods including varying the tow speed. Sonardyne has considerable experience of this application for its acoustic technology having first developed bundle monitoring equipment for Subsea 7 in 1993. At that time, depth monitoring transponders deployed at regular intervals along the bundle were connected via data highway cable, to master units located on the tow head. These sent data acousti- cally to the towmaster and received commands back, such as to open the valves that controlled flooding of the bun- dles. The technology proved very effective as any damage sustained to a bundle during tow-out is extremely costly to rectify. For the latest tows, Sonardyne’s new Compatt 6 transponders will be deployed at intervals of around 700 to 1000 metres along each bundle. Sonardyne Lodestar attitude and heading reference sensors will also be deployed at each end of the bundles and at specified intervals along them. Lodestars contain highly accurate ring laser gyros that will enable the shape and attitude of the bundle to be monitored. The pressure of the carrier gas (nitrogen) within the pipes will be monitored by sensors at each end of the bundle and this data, along with the angle of the towing wires will also be transmitted. Andrew McKeown, a Surveyor at Subsea 7, said: “This new Sonardyne 6G technology will allow Subsea 7 to provide continuous, stable and repeatable data during the transit of the bundles to the offshore location. This is a major advance in monitoring the bundle attitude during tow operations and will provide valid and accurate data for the towmaster to safely control the depth of the bundle.”

31

31

33

33