Page 46: of Marine Technology Magazine (March 2011)

Subsea Vehicles: AUV, ROV, UUV Annual

Read this page in Pdf, Flash or Html5 edition of March 2011 Marine Technology Magazine

46 MTR March 2011 tional features such as proven safety, longer cycle life, bet- ter calendar life and a wide operating temperature range, including superior low-temperature performance com- pared to standard iron phosphate technology.

Traditional Li-ion batteries are made with transition metal oxide cathode materials such as Lithium Cobalt

Oxide or Lithium Nickel Cobalt Aluminum Oxide.

Lithium-iron phosphate (LiFePO4) batteries are recharge- able Li-ion batteries that use LiFePO4 as the cathode material.

This low cost, naturally-occurring mineral offers excel- lent thermal stability. The use of iron phosphate material in Li-ion batteries was first discovered and patented in 1997 by Dr. Goodenough from the University of Texas.

Super-Phosphate™ is being incorporated into a variety of marine applications that require high energy and the safest operation. The primary advantage of iron phosphate over metal oxide based Li-ion is increased abuse tolerance, because the cell is less prone to reactivity under such con- ditions. Both Li-ion and lithium-iron phosphate batteries offer their own unique advantages and provide options, so marine designers can select the best power source to fit the application.

Cell Selection and Safety

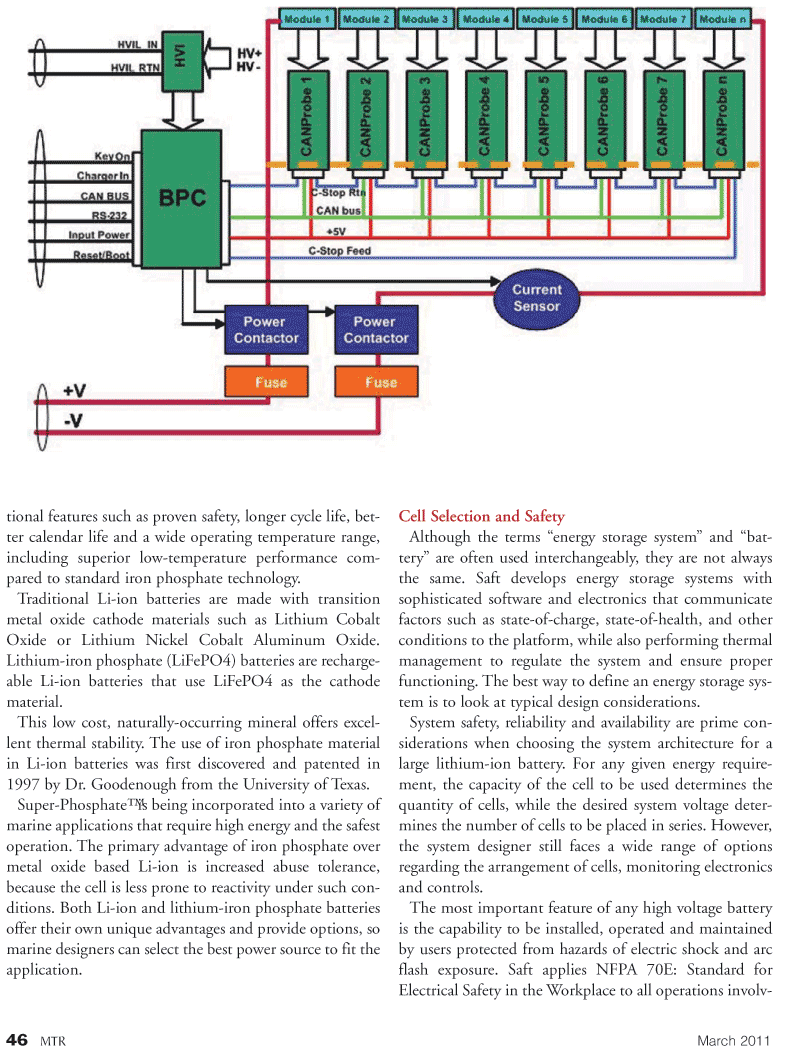

Although the terms “energy storage system” and “bat- tery” are often used interchangeably, they are not always the same. Saft develops energy storage systems with sophisticated software and electronics that communicate factors such as state-of-charge, state-of-health, and other conditions to the platform, while also performing thermal management to regulate the system and ensure proper functioning. The best way to define an energy storage sys- tem is to look at typical design considerations.

System safety, reliability and availability are prime con- siderations when choosing the system architecture for a large lithium-ion battery. For any given energy require- ment, the capacity of the cell to be used determines the quantity of cells, while the desired system voltage deter- mines the number of cells to be placed in series. However, the system designer still faces a wide range of options regarding the arrangement of cells, monitoring electronics and controls.

The most important feature of any high voltage battery is the capability to be installed, operated and maintained by users protected from hazards of electric shock and arc flash exposure. Saft applies NFPA 70E: Standard for

Electrical Safety in the Workplace to all operations involv-

45

45

47

47