Page 46: of Marine Technology Magazine (June 2011)

Hydrographic Survey

Read this page in Pdf, Flash or Html5 edition of June 2011 Marine Technology Magazine

The 2007 JIP focused on identifying active production solutions for deepwater and/or long offset tie-backs to host facilities or to shore. The state-of-the-industry report highlighted available equipment and technology, current operational status and future strategic direction within this industry subset.

One deliverable of the new JIP is a user-friendly, system- design database that consolidates objective and up-to-date component information, allowing operators to match their asset needs with the most appropriate conventional, enhanced and active subsea production technologies. “In short, the JIP will offer industry a mechanism for optimizing design schemes and field development archi- tecture for the efficient delivery of hydrocarbons in arctic and subarctic waters,” said Ball.

The current study will incorporate information from the 2007 study with additional updated information on con- ventional and emerging subsea technologies and relate them specifically to the participants’ interests in offshore

Newfoundland, Labrador and arctic environments world- wide.

Existing developments in offshore Newfoundland include Hibernia, Terra Nova and White Rose, with

Hebron expected to begin development in the near term.

Step outs from existing facilities are contemplated, with one already completed on the White Rose Field.

Frontier and deepwater prospects offshore Eastern

Canada which would benefit from the JIP research include Orphan Basin, Laurenian Basin, Central

Ridge/Flemish Pass and the Labrador Shelf, says Mike

Paulin, INTECSEA Operations director for Canada. “The Labrador Shelf is a very harsh environment and will require innovative solutions to overcome the chal- lenges,” said Paulin.

The Labrador Shelf includes water depths up to 9,900 ft. and experiences waves up to 43 ft. high. Ice conditions on the Labrador Shelf are significant, with pack ice reach- ing a thickness up to 23 feet and icebergs a serious threat from July through October. To address these and other frontier issues, the JIP will generate a database with an interface tool that allows operators and developers to screen and select from a broad array of active production technologies, including separation, boosting, compression and direct electric heating systems, suitable for stranded and existing field developments.

Inherent evaluations include system installability, oper- ability, reliability and maintainability issues specific to the environment, as well as technology maturity and any additional fit-for-purpose qualification programs. Efforts of the JIP will redefine current industry limits for field development architecture in cold-climate regions while improving expectations for systems that are flexible and responsive.

The JIP also is tackling prominent offshore arctic issues, including the impact of iceberg scouring on subsea facili- ties, said Paulin. “A floater can be relocated but subsea facilities cannot,” he said.

Arctic operators, particularly offshore Eastern Canada, dig huge holes—60 ft. deep and up to 1,080 ft. to avoid ice scouring, said Paulin. “This approach is costly, time- intensive and will not sustain the level of subsea development the industry antici- pates,” he said.

The JIP is led out of INTECSEA’s St.

John’s office. INTECSEA personnel sup- porting the project include Ian Ball; Dr.

Kalyana Janardhanan, group lead Subsea

Active Production Technology; Richard

Voight, executive engineer; Cody Moffitt,

Subsea Discipline manager; and Julie Burke,

Subsea engineer.

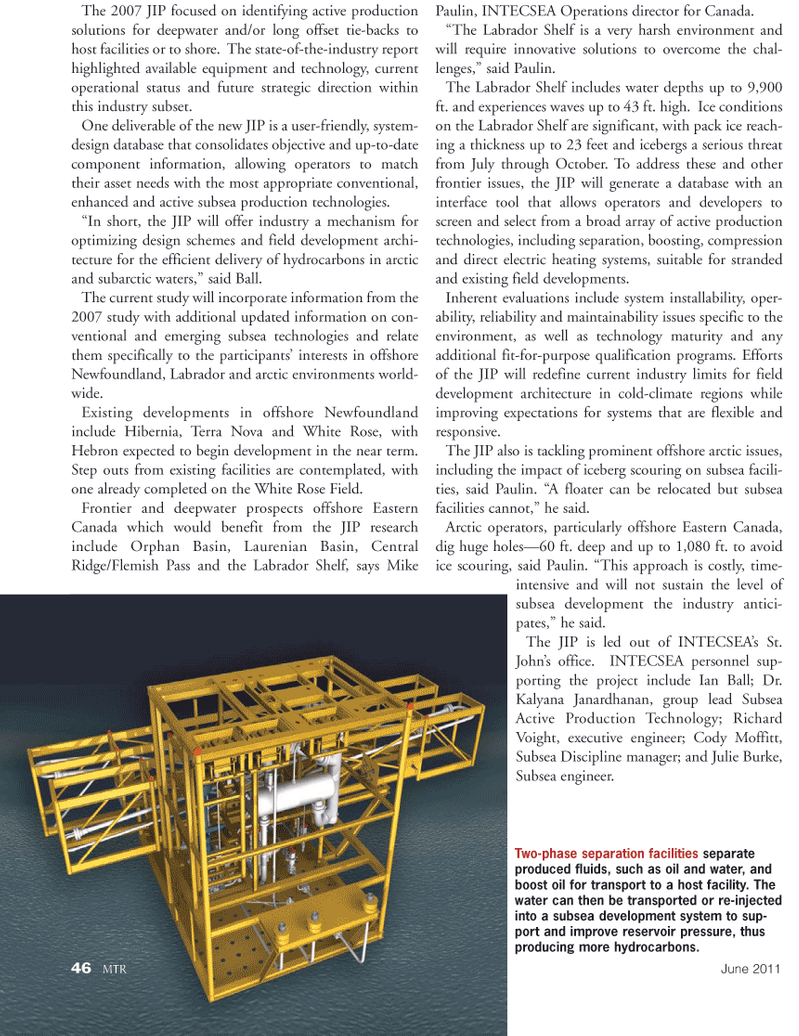

Two-phase separation facilities separate produced fluids, such as oil and water, and boost oil for transport to a host facility. The water can then be transported or re-injected into a subsea development system to sup- port and improve reservoir pressure, thus producing more hydrocarbons. 46 MTR June 2011

45

45

47

47