Page 42: of Marine Technology Magazine (October 2011)

Ocean Engineering & Design

Read this page in Pdf, Flash or Html5 edition of October 2011 Marine Technology Magazine

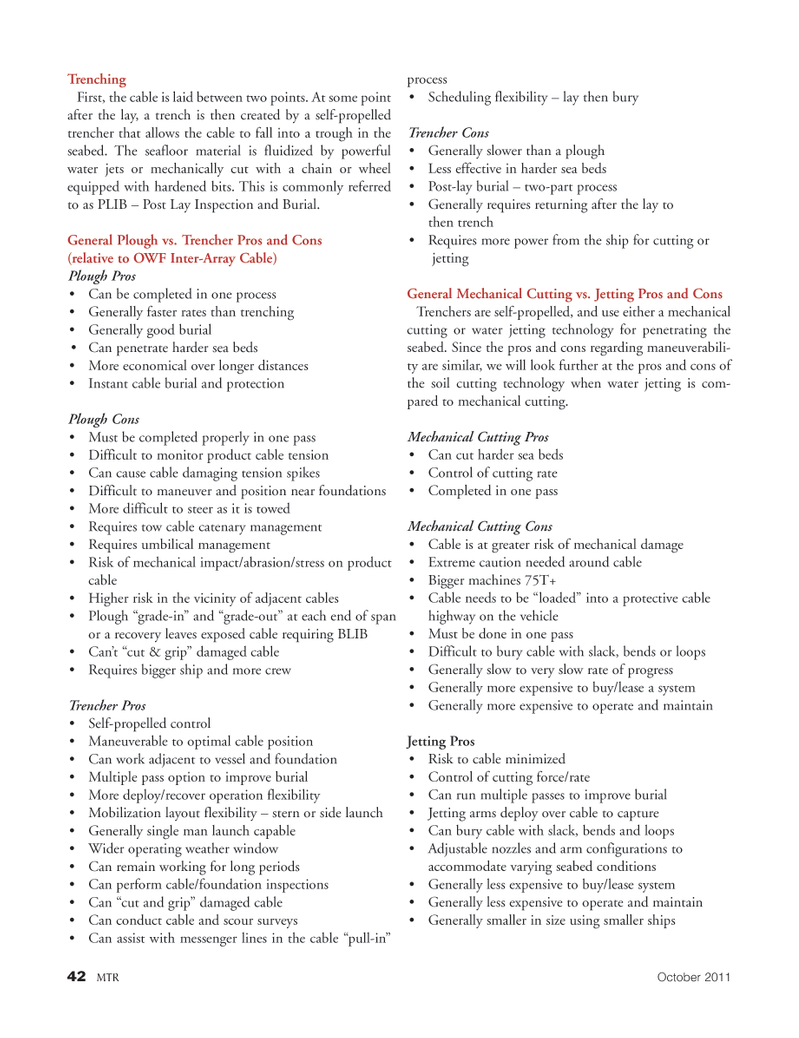

42MTROctober 2011Trenching First, the cable is laid between two points. At some point after the lay, a trench is then created by a self-propelled trencher that allows the cable to fall into a trough in the seabed. The seafloor material is fluidized by powerful water jets or mechanically cut with a chain or wheelequipped with hardened bits. This is commonly referred to as PLIB ? Post Lay Inspection and Burial. General Plough vs. Trencher Pros and Cons (relative to OWF Inter-Array Cable) Plough Pros Can be completed in one process Generally faster rates than trenching Generally good burial Can penetrate harder sea beds More economical over longer distances Instant cable burial and protection Plough Cons Must be completed properly in one pass Difficult to monitor product cable tension Can cause cable damaging tension spikes Difficult to maneuver and position near foundations More difficult to steer as it is towed Requires tow cable catenary management Requires umbilical management Risk of mechanical impact/abrasion/stress on product cableHigher risk in the vicinity of adjacent cables Plough ?grade-in? and ?grade-out? at each end of span or a recovery leaves exposed cable requiring BLIB Can?t ?cut & grip? damaged cable Requires bigger ship and more crew Trencher Pros Self-propelled control Maneuverable to optimal cable position Can work adjacent to vessel and foundation Multiple pass option to improve burial More deploy/recover operation flexibility Mobilization layout flexibility ? stern or side launch Generally single man launch capable Wider operating weather window Can remain working for long periods Can perform cable/foundation inspections Can ?cut and grip? damaged cable Can conduct cable and scour surveys Can assist with messenger lines in the cable ?pull-in? process Scheduling flexibility ? lay then bury Trencher Cons Generally slower than a plough Less effective in harder sea beds Post-lay burial ? two-part process Generally requires returning after the lay to then trench Requires more power from the ship for cutting or jettingGeneral Mechanical Cutting vs. Jetting Pros and Cons Trenchers are self-propelled, and use either a mechanical cutting or water jetting technology for penetrating theseabed. Since the pros and cons regarding maneuverabili- ty are similar, we will look further at the pros and cons of the soil cutting technology when water jetting is com-pared to mechanical cutting. Mechanical Cutting Pros Can cut harder sea beds Control of cutting rate Completed in one pass Mechanical Cutting Cons Cable is at greater risk of mechanical damage Extreme caution needed around cable Bigger machines 75T+ Cable needs to be ?loaded? into a protective cable highway on the vehicle Must be done in one pass Difficult to bury cable with slack, bends or loops Generally slow to very slow rate of progress Generally more expensive to buy/lease a system Generally more expensive to operate and maintain Jetting Pros Risk to cable minimized Control of cutting force/rate Can run multiple passes to improve burial Jetting arms deploy over cable to capture Can bury cable with slack, bends and loops Adjustable nozzles and arm configurations to accommodate varying seabed conditions Generally less expensive to buy/lease system Generally less expensive to operate and maintain Generally smaller in size using smaller ships MTR#8 (34-49):MTR Layouts 10/11/2011 8:52 AM Page 42

41

41

43

43