Page 56: of Marine Technology Magazine (October 2011)

Ocean Engineering & Design

Read this page in Pdf, Flash or Html5 edition of October 2011 Marine Technology Magazine

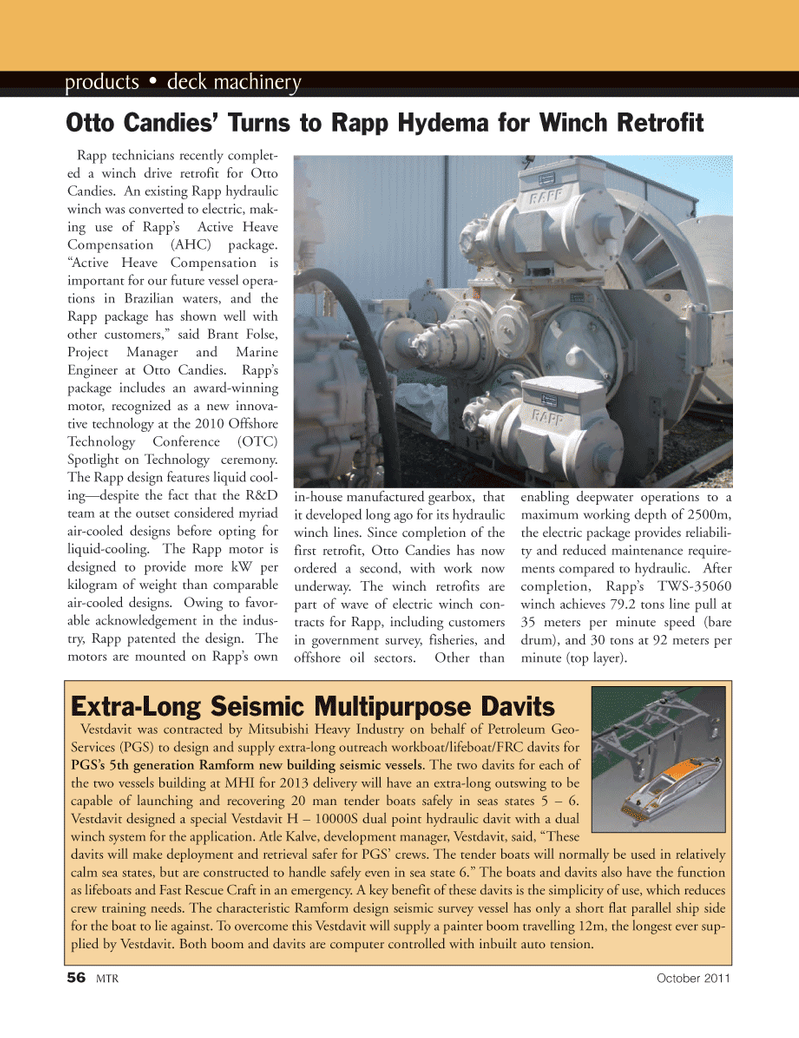

56MTROctober2011 products deck machinery Rapp technicians recently complet- ed a winch drive retrofit for Otto Candies. An existing Rapp hydraulic winch was converted to electric, mak- ing use of Rapp?s Active Heave Compensation (AHC) package.?Active Heave Compensation is important for our future vessel opera- tions in Brazilian waters, and the Rapp package has shown well with other customers,? said Brant Folse, Project Manager and Marine Engineer at Otto Candies. Rapp?s package includes an award-winning motor, recognized as a new innova- tive technology at the 2010 Offshore Technology Conference (OTC) Spotlight on Technology ceremony. The Rapp design features liquid cool- ing?despite the fact that the R&Dteam at the outset considered myriad air-cooled designs before opting for liquid-cooling. The Rapp motor is designed to provide more kW per kilogram of weight than comparable air-cooled designs. Owing to favor- able acknowledgement in the indus- try, Rapp patented the design. The motors are mounted on Rapp?s own in-house manufactured gearbox, that it developed long ago for its hydraulic winch lines. Since completion of the first retrofit, Otto Candies has now ordered a second, with work now underway. The winch retrofits are part of wave of electric winch con- tracts for Rapp, including customers in government survey, fisheries, and offshore oil sectors. Other than enabling deepwater operations to a maximum working depth of 2500m, the electric package provides reliabili- ty and reduced maintenance require- ments compared to hydraulic. After completion, Rapp?s TWS-35060 winch achieves 79.2 tons line pull at 35 meters per minute speed (bare drum), and 30 tons at 92 meters per minute (top layer). Otto Candies? Turns to Rapp Hydema for Winch Retrofit Extra-Long Seismic Multipurpose DavitsVestdavit was contracted by Mitsubishi Heavy Industry on behalf of Petroleum Geo- Services (PGS) to design and supply extra-long outreach workboat/lifeboat/FRC davits for PGS?s 5th generation Ramform new building seismic vessels . The two davits for each of the two vessels building at MHI for 2013 delivery will have an extra-long outswing to be capable of launching and recovering 20 man tender boats safely in seas states 5 ? 6. Vestdavit designed a special Vestdavit H ? 10000S dual point hydraulic davit with a dual winch system for the application. Atle Kalve, development manager, Vestdavit, said, ?These davits will make deployment and retrieval safer for PGS? crews. The tender boats will normally be used in relatively calm sea states, but are constructed to handle safely even in sea state 6.? The boats and davits also have the function as lifeboats and Fast Rescue Craft in an emergency. A key benefit of these davits is the simplicity of use, which reduces crew training needs. The characteristic Ramform design seismic survey vessel has only a short flat parallel ship side for the boat to lie against. To overcome this Vestdavit will supply a painter boom travelling 12m, the longest ever sup- plied by Vestdavit. Both boom and davits are computer controlled with inbuilt auto tension. MTR#8 (50-64):MTR Layouts 10/11/2011 9:11 AM Page 56

55

55

57

57