Page 60: of Marine Technology Magazine (October 2011)

Ocean Engineering & Design

Read this page in Pdf, Flash or Html5 edition of October 2011 Marine Technology Magazine

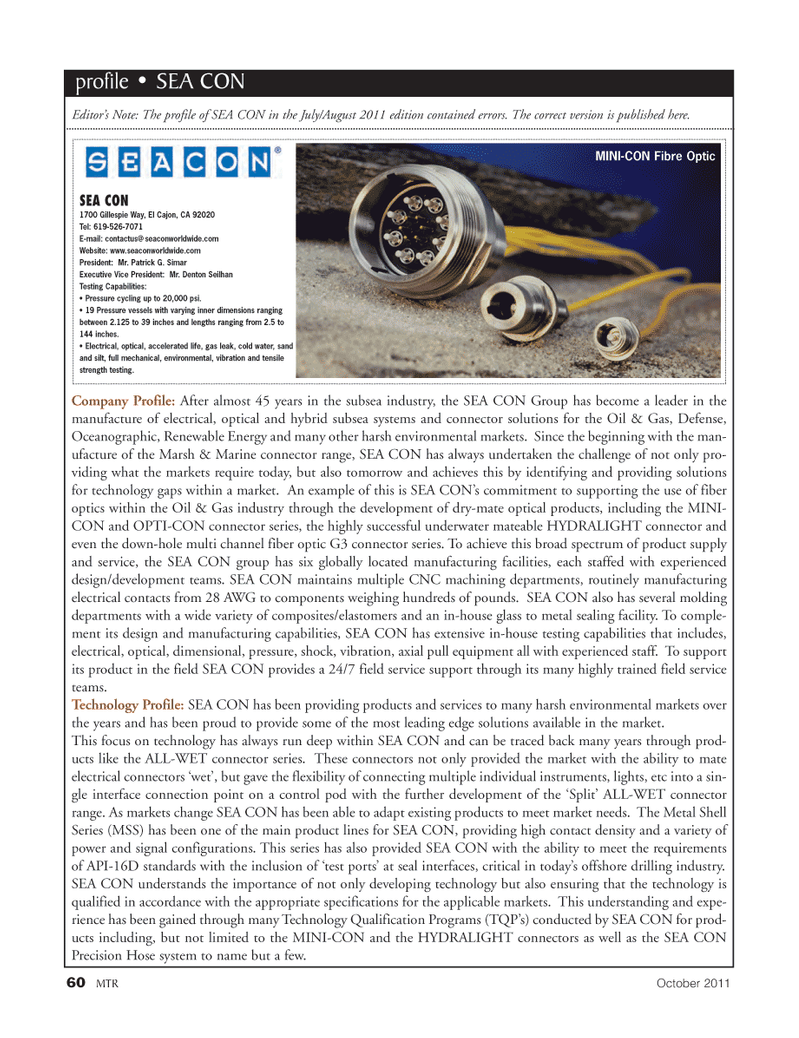

Editor?s Note: The profile of SEA CON in the July/August 2011 edition contained errors. The correct version is published here. Company Profile: After almost 45 years in the subsea industry, the SEA CON Group has become a leader in the manufacture of electrical, optical and hybrid subsea systems and connector solutions for the Oil & Gas, Defense, Oceanographic, Renewable Energy and many other harsh environmental markets. Since the beginning with the man- ufacture of the Marsh & Marine connector range, SEA CON has always undertaken the challenge of not only pro- viding what the markets require today, but also tomorrow and achieves this by identifying and providing solutions for technology gaps within a market. An example of this is SEA CON?s commitment to supporting the use of fiber optics within the Oil & Gas industry through the development of dry-mate optical products, including the MINI- CON and OPTI-CON connector series, the highly successful underwater mateable HYDRALIGHT connector and even the down-hole multi channel fiber optic G3 connector series. To achieve this broad spectrum of product supply and service, the SEA CON group has six globally located manufacturing facilities, each staffed with experienced design/development teams. SEA CON maintains multiple CNC machining departments, routinely manufacturing electrical contacts from 28 AWG to components weighing hundreds of pounds. SEA CON also has several molding departments with a wide variety of composites/elastomers and an in-house glass to metal sealing facility. To comple- ment its design and manufacturing capabilities, SEA CON has extensive in-house testing capabilities that includes, electrical, optical, dimensional, pressure, shock, vibration, axial pull equipment all with experienced staff. To support its product in the field SEA CON provides a 24/7 field service support through its many highly trained field service teams.Technology Profile: SEA CON has been providing products and services to many harsh environmental markets over the years and has been proud to provide some of the most leading edge solutions available in the market. This focus on technology has always run deep within SEA CON and can be traced back many years through prod- ucts like the ALL-WET connector series. These connectors not only provided the market with the ability to mate electrical connectors ?wet?, but gave the flexibility of connecting multiple individual instruments, lights, etc into a sin- gle interface connection point on a control pod with the further development of the ?Split? ALL-WET connector range. As markets change SEA CON has been able to adapt existing products to meet market needs. The Metal Shell Series (MSS) has been one of the main product lines for SEA CON, providing high contact density and a variety of power and signal configurations. This series has also provided SEA CON with the ability to meet the requirements of API-16D standards with the inclusion of ?test ports? at seal interfaces, critical in today?s offshore drilling industry. SEA CON understands the importance of not only developing technology but also ensuring that the technology is qualified in accordance with the appropriate specifications for the applicable markets. This understanding and expe- rience has been gained through many Technology Qualification Programs (TQP?s) conducted by SEA CON for prod- ucts including, but not limited to the MINI-CON and the HYDRALIGHT connectors as well as the SEA CON Precision Hose system to name but a few. 60MTROctober2011 profile SEA CONSEA CON1700 Gillespie Way, El Cajon, CA 92020 Tel: 619-526-7071 E-mail: contactus@ seaconworldwide.comWebsite: www.seaconworldwide.com President: Mr. Patrick G. Simar Executive Vice President: Mr. Denton Seilhan Testing Capabilities: Pressure cycling up to 20,000 psi. 19 Pressure vessels with varying inner dimensions ranging between 2.125 to 39 inches and lengths ranging from 2.5 to 144 inches. Electrical, optical, accelerated life, gas leak, cold water, sand and silt, full mechanical, environmental, vibration and tensile strength testing. MINI-CON Fibre Optic MTR#8 (50-64):MTR Layouts 10/11/2011 9:15 AM Page 60

59

59

61

61