Page 12: of Marine Technology Magazine (January 2012)

Offshore Inspection, Repair & Maintenance

Read this page in Pdf, Flash or Html5 edition of January 2012 Marine Technology Magazine

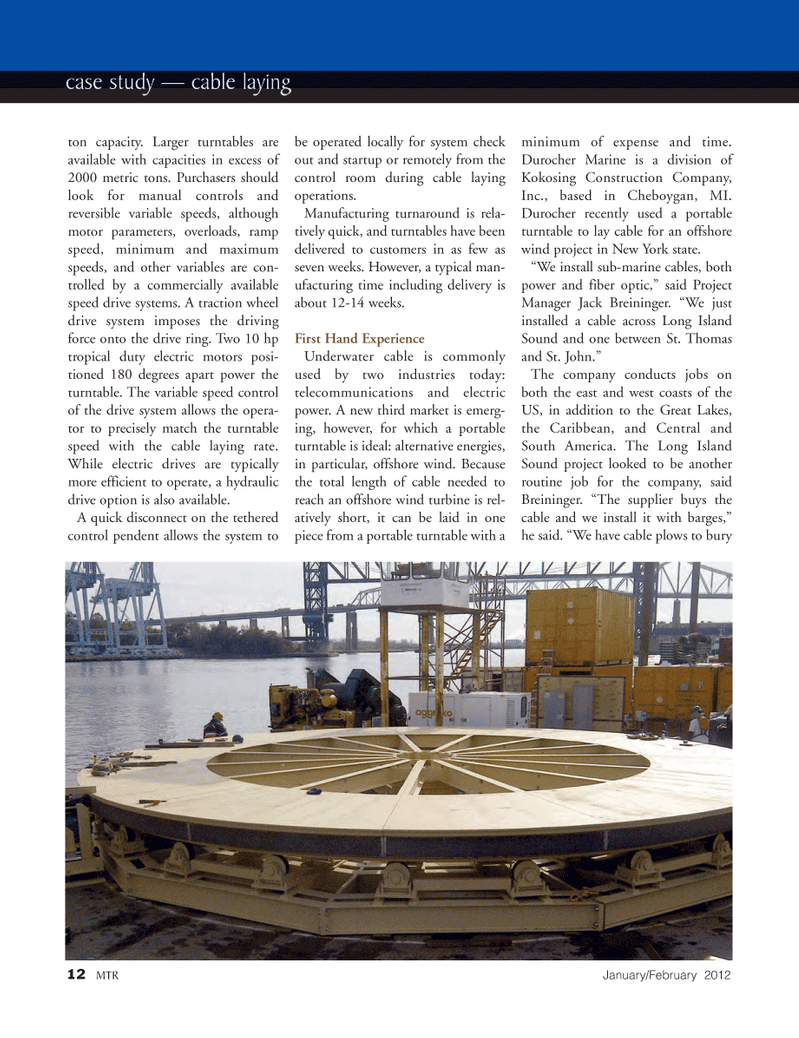

ton capacity. Larger turntables are available with capacities in excess of 2000 metric tons. Purchasers should look for manual controls and reversible variable speeds, although motor parameters, overloads, ramp speed, minimum and maximumspeeds, and other variables are con- trolled by a commercially available speed drive systems. A traction wheel drive system imposes the driving force onto the drive ring. Two 10 hp tropical duty electric motors posi- tioned 180 degrees apart power the turntable. The variable speed control of the drive system allows the opera- tor to precisely match the turntable speed with the cable laying rate.While electric drives are typically more efficient to operate, a hydraulic drive option is also available. A quick disconnect on the tethered control pendent allows the system to be operated locally for system checkout and startup or remotely from the control room during cable laying operations.Manufacturing turnaround is rela- tively quick, and turntables have been delivered to customers in as few as seven weeks. However, a typical man- ufacturing time including delivery is about 12-14 weeks. First Hand Experience Underwater cable is commonly used by two industries today:telecommunications and electricpower. A new third market is emerg- ing, however, for which a portable turntable is ideal: alternative energies, in particular, offshore wind. Because the total length of cable needed toreach an offshore wind turbine is rel- atively short, it can be laid in one piece from a portable turntable with a minimum of expense and time.Durocher Marine is a division of Kokosing Construction Company, Inc., based in Cheboygan, MI. Durocher recently used a portable turntable to lay cable for an offshore wind project in New York state. ?We install sub-marine cables, both power and fiber optic,? said Project Manager Jack Breininger. ?We just installed a cable across Long Island Sound and one between St. Thomas and St. John.? The company conducts jobs onboth the east and west coasts of the US, in addition to the Great Lakes, the Caribbean, and Central andSouth America. The Long Island Sound project looked to be another routine job for the company, said Breininger. ?The supplier buys the cable and we install it with barges,? he said. ?We have cable plows to bury case study ? cable laying 12MTRJanuary/February 2012 MTR#1 (1-17):MTR Layouts 1/4/2012 2:10 PM Page 12

11

11

13

13