Page 20: of Marine Technology Magazine (January 2012)

Offshore Inspection, Repair & Maintenance

Read this page in Pdf, Flash or Html5 edition of January 2012 Marine Technology Magazine

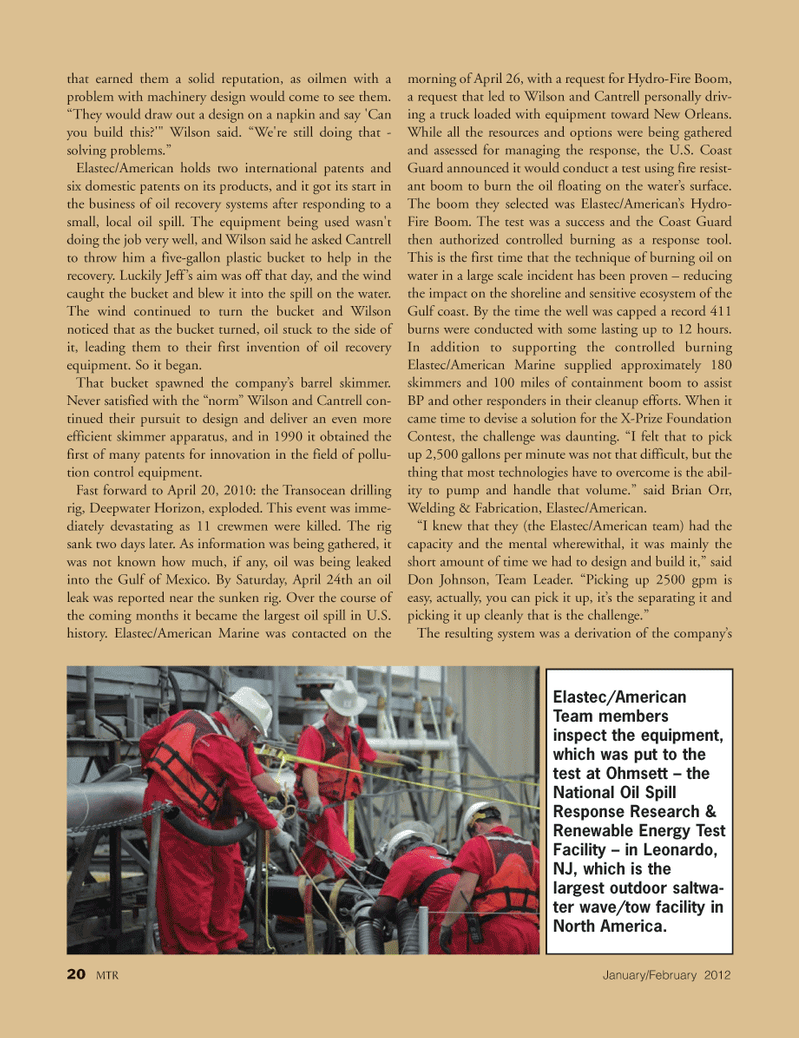

that earned them a solid reputation, as oilmen with a problem with machinery design would come to see them. ?They would draw out a design on a napkin and say 'Can you build this?'" Wilson said. ?We're still doing that - solving problems.? Elastec/American holds two international patents and six domestic patents on its products, and it got its start in the business of oil recovery systems after responding to a small, local oil spill. The equipment being used wasn't doing the job very well, and Wilson said he asked Cantrell to throw him a five-gallon plastic bucket to help in the recovery. Luckily Jeff?s aim was off that day, and the wind caught the bucket and blew it into the spill on the water. The wind continued to turn the bucket and Wilson noticed that as the bucket turned, oil stuck to the side ofit, leading them to their first invention of oil recovery equipment. So it began. That bucket spawned the company?s barrel skimmer. Never satisfied with the ?norm? Wilson and Cantrell con- tinued their pursuit to design and deliver an even more efficient skimmer apparatus, and in 1990 it obtained thefirst of many patents for innovation in the field of pollu- tion control equipment. Fast forward to April 20, 2010: the Transocean drilling rig, Deepwater Horizon, exploded. This event was imme- diately devastating as 11 crewmen were killed. The rig sank two days later. As information was being gathered, it was not known how much, if any, oil was being leaked into the Gulf of Mexico. By Saturday, April 24th an oil leak was reported near the sunken rig. Over the course of the coming months it became the largest oil spill in U.S.history. Elastec/American Marine was contacted on the morning of April 26, with a request for Hydro-Fire Boom, a request that led to Wilson and Cantrell personally driv- ing a truck loaded with equipment toward New Orleans. While all the resources and options were being gathered and assessed for managing the response, the U.S. Coast Guard announced it would conduct a test using fire resist- ant boom to burn the oil floating on the water?s surface. The boom they selected was Elastec/American?s Hydro- Fire Boom. The test was a success and the Coast Guard then authorized controlled burning as a response tool. This is the first time that the technique of burning oil onwater in a large scale incident has been proven ? reducing the impact on the shoreline and sensitive ecosystem of the Gulf coast. By the time the well was capped a record 411 burns were conducted with some lasting up to 12 hours. In addition to supporting the controlled burning Elastec/American Marine supplied approximately 180 skimmers and 100 miles of containment boom to assistBP and other responders in their cleanup efforts. When it came time to devise a solution for the X-Prize Foundation Contest, the challenge was daunting. ?I felt that to pickup 2,500 gallons per minute was not that difficult, but thething that most technologies have to overcome is the abil- ity to pump and handle that volume.? said Brian Orr, Welding & Fabrication, Elastec/American. ?I knew that they (the Elastec/American team) had the capacity and the mental wherewithal, it was mainly the short amount of time we had to design and build it,? said Don Johnson, Team Leader. ?Picking up 2500 gpm is easy, actually, you can pick it up, it?s the separating it and picking it up cleanly that is the challenge.?The resulting system was a derivation of the company?s 20MTRJanuary/February 2012 Elastec/AmericanTeam members inspect the equipment,which was put to thetest at Ohmsett ? theNational Oil SpillResponse Research & Renewable Energy Test Facility ? in Leonardo, NJ, which is thelargest outdoor saltwa- ter wave/tow facility inNorth America. MTR#1 (18-33):MTR Layouts 1/4/2012 12:59 PM Page 20

19

19

21

21