Page 41: of Marine Technology Magazine (January 2012)

Offshore Inspection, Repair & Maintenance

Read this page in Pdf, Flash or Html5 edition of January 2012 Marine Technology Magazine

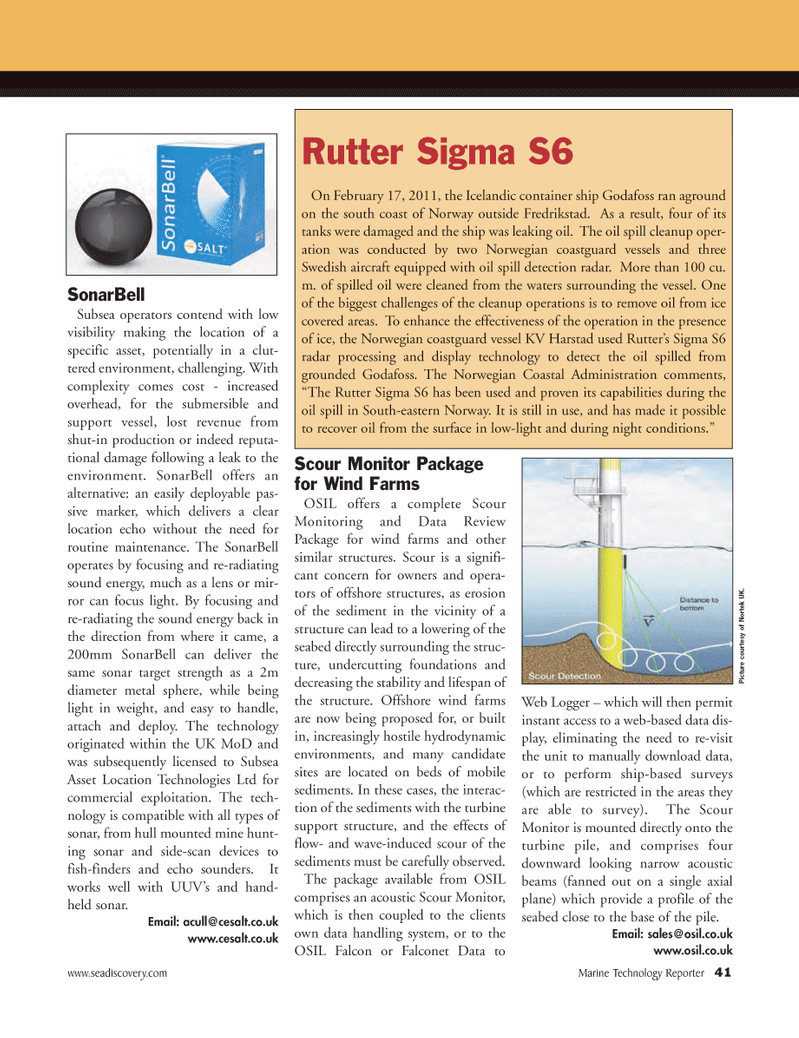

SonarBellSubsea operators contend with low visibility making the location of aspecific asset, potentially in a clut-tered environment, challenging. With complexity comes cost - increased overhead, for the submersible and support vessel, lost revenue from shut-in production or indeed reputa- tional damage following a leak to the environment. SonarBell offers an alternative: an easily deployable pas- sive marker, which delivers a clear location echo without the need forroutine maintenance. The SonarBell operates by focusing and re-radiating sound energy, much as a lens or mir- ror can focus light. By focusing and re-radiating the sound energy back in the direction from where it came, a 200mm SonarBell can deliver the same sonar target strength as a 2m diameter metal sphere, while being light in weight, and easy to handle, attach and deploy. The technology originated within the UK MoD and was subsequently licensed to Subsea Asset Location Technologies Ltd for commercial exploitation. The tech- nology is compatible with all types ofsonar, from hull mounted mine hunt- ing sonar and side-scan devices tofish-finders and echo sounders. It works well with UUV?s and hand- held sonar. Email: acull@ cesalt.co.ukwww.cesalt.co.uk Scour Monitor Packagefor Wind Farms OSIL offers a complete ScourMonitoring and Data Review Package for wind farms and other similar structures. Scour is a signifi- cant concern for owners and opera- tors of offshore structures, as erosion of the sediment in the vicinity of astructure can lead to a lowering of the seabed directly surrounding the struc- ture, undercutting foundations and decreasing the stability and lifespan of the structure. Offshore wind farms are now being proposed for, or built in, increasingly hostile hydrodynamic environments, and many candidate sites are located on beds of mobile sediments. In these cases, the interac- tion of the sediments with the turbinesupport structure, and the effects of flow- and wave-induced scour of the sediments must be carefully observed. The package available from OSIL comprises an acoustic Scour Monitor, which is then coupled to the clientsown data handling system, or to the OSIL Falcon or Falconet Data to Web Logger ? which will then permit instant access to a web-based data dis- play, eliminating the need to re-visit the unit to manually download data, or to perform ship-based surveys (which are restricted in the areas they are able to survey). The Scour Monitor is mounted directly onto the turbine pile, and comprises fourdownward looking narrow acoustic beams (fanned out on a single axialplane) which provide a profile of the seabed close to the base of the pile. Email: sales@ osil.co.uk www.osil.co.uk www.seadiscovery.com Marine Technology Reporter 41Rutter Sigma S6 On February 17, 2011, the Icelandic container ship Godafoss ran aground on the south coast of Norway outside Fredrikstad. As a result, four of its tanks were damaged and the ship was leaking oil. The oil spill cleanup oper- ation was conducted by two Norwegian coastguard vessels and three Swedish aircraft equipped with oil spill detection radar. More than 100 cu. m. of spilled oil were cleaned from the waters surrounding the vessel. One of the biggest challenges of the cleanup operations is to remove oil from ice covered areas. To enhance the effectiveness of the operation in the presence of ice, the Norwegian coastguard vessel KV Harstad used Rutter?s Sigma S6 radar processing and display technology to detect the oil spilled from grounded Godafoss. The Norwegian Coastal Administration comments, ?The Rutter Sigma S6 has been used and proven its capabilities during the oil spill in South-eastern Norway. It is still in use, and has made it possible to recover oil from the surface in low-light and during night conditions.? Picture courtesy of Nortek UK. MTR#1 (34-48):MTR Layouts 1/3/2012 10:56 AM Page 41

40

40

42

42