Page 32: of Marine Technology Magazine (May 2012)

Hydrographic Survey

Read this page in Pdf, Flash or Html5 edition of May 2012 Marine Technology Magazine

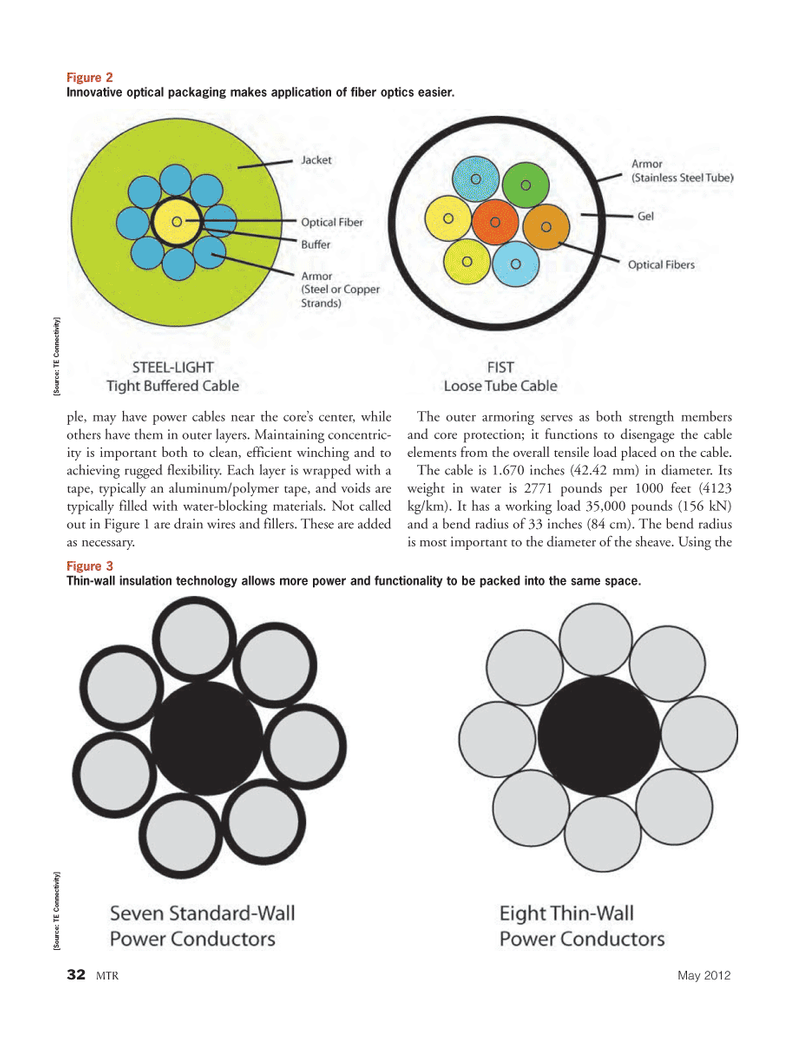

32MTRMay 2012ple, may have power cables near the core?s center, while others have them in outer layers. Maintaining concentric- ity is important both to clean, efficient winching and to achieving rugged flexibility. Each layer is wrapped with a tape, typically an aluminum/polymer tape, and voids are typically filled with water-blocking materials. Not called out in Figure 1 are drain wires and fillers. These are added as necessary. The outer armoring serves as both strength members and core protection; it functions to disengage the cable elements from the overall tensile load placed on the cable. The cable is 1.670 inches (42.42 mm) in diameter. Its weight in water is 2771 pounds per 1000 feet (4123 kg/km). It has a working load 35,000 pounds (156 kN) and a bend radius of 33 inches (84 cm). The bend radius is most important to the diameter of the sheave. Using the [Source: TE Connectivity] Figure 2 Innovative optical packaging makes application of fiber optics easier. [Source: TE Connectivity] Figure 3 Thin-wall insulation technology allows more power and functionality to be packed into the same space. MTR#4 (18-33):MTR Layouts 4/27/2012 1:01 PM Page 32

31

31

33

33