Page 51: of Marine Technology Magazine (June 2012)

AUV Arctic Operations

Read this page in Pdf, Flash or Html5 edition of June 2012 Marine Technology Magazine

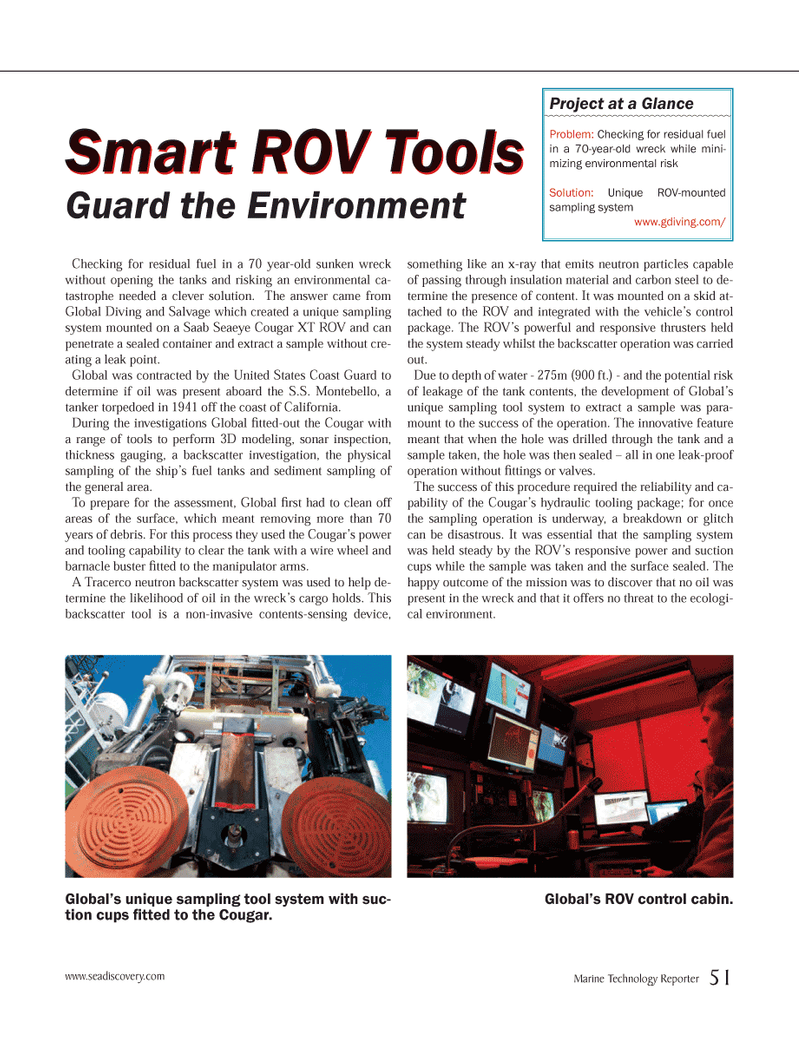

Checking for residual fuel in a 70 year-old sunken wreck without opening the tanks and risking an environmental ca- tastrophe needed a clever solution. The answer came from Global Diving and Salvage which created a unique sampling system mounted on a Saab Seaeye Cougar XT ROV and can penetrate a sealed container and extract a sample without cre- ating a leak point.Global was contracted by the United States Coast Guard to determine if oil was present aboard the S.S. Montebello, a tanker torpedoed in 1941 off the coast of California. During the investigations Global Þ tted-out the Cougar with a range of tools to perform 3D modeling, sonar inspection, thickness gauging, a backscatter investigation, the physical sampling of the shipÕs fuel tanks and sediment sampling of the general area. To prepare for the assessment, Global Þ rst had to clean off areas of the surface, which meant removing more than 70 years of debris. For this process they used the CougarÕs power and tooling capability to clear the tank with a wire wheel and barnacle buster Þ tted to the manipulator arms. A Tracerco neutron backscatter system was used to help de- termine the likelihood of oil in the wreckÕs cargo holds. This backscatter tool is a non-invasive contents-sensing device, something like an x-ray that emits neutron particles capable of passing through insulation material and carbon steel to de-termine the presence of content. It was mounted on a skid at- tached to the ROV and integrated with the vehicleÕs control package. The ROVÕs powerful and responsive thrusters held the system steady whilst the backscatter operation was carried out.Due to depth of water - 275m (900 ft.) - and the potential risk of leakage of the tank contents, the development of GlobalÕs unique sampling tool system to extract a sample was para- mount to the success of the operation. The innovative feature meant that when the hole was drilled through the tank and a sample taken, the hole was then sealed Ð all in one leak-proof operation without Þ ttings or valves. The success of this procedure required the reliability and ca-pability of the CougarÕs hydraulic tooling package; for once the sampling operation is underway, a breakdown or glitch can be disastrous. It was essential that the sampling system was held steady by the ROVÕs responsive power and suction cups while the sample was taken and the surface sealed. The happy outcome of the mission was to discover that no oil was present in the wreck and that it offers no threat to the ecologi- cal environment. Global?s unique sampling tool system with suc- tion cups Þ tted to the Cougar. Global?s ROV control cabin. Smart ROV Tools Smart ROV Tools Guard the Environment Project at a GlanceProblem: Checking for residual fuel in a 70-year-old wreck while mini- mizing environmental risk Solution: Unique ROV-mounted sampling system www.gdiving.com/ www.seadiscovery.com Marine Technology Reporter 51MTR #5 (50-64).indd 51MTR #5 (50-64).indd 515/31/2012 1:09:33 PM5/31/2012 1:09:33 PM

50

50

52

52