Page 46: of Marine Technology Magazine (November 2013)

Fresh Water Monitoring & Sensors

Read this page in Pdf, Flash or Html5 edition of November 2013 Marine Technology Magazine

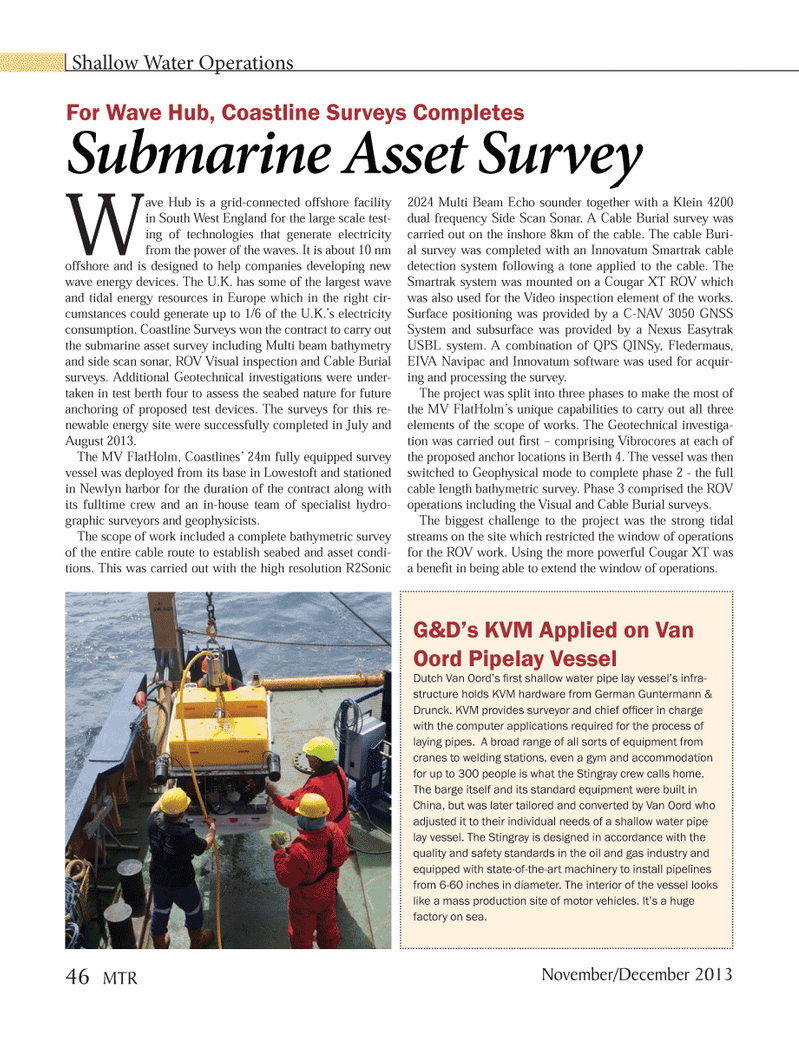

Wave Hub is a grid-connected offshore facility in South West England for the large scale test- ing of technologies that generate electricity from the power of the waves. It is about 10 nm offshore and is designed to help companies developing new wave energy devices. The U.K. has some of the largest wave and tidal energy resources in Europe which in the right cir- cumstances could generate up to 1/6 of the U.K.?s electricity consumption. Coastline Surveys won the contract to carry out the submarine asset survey including Multi beam bathymetry and side scan sonar, ROV Visual inspection and Cable Burial surveys. Additional Geotechnical investigations were under- taken in test berth four to assess the seabed nature for future anchoring of proposed test devices. The surveys for this re- newable energy site were successfully completed in July and August 2013. The MV FlatHolm, Coastlines? 24m fully equipped survey vessel was deployed from its base in Lowestoft and stationed in Newlyn harbor for the duration of the contract along with its fulltime crew and an in-house team of specialist hydro- graphic surveyors and geophysicists. The scope of work included a complete bathymetric survey of the entire cable route to establish seabed and asset condi-tions. This was carried out with the high resolution R2Sonic 2024 Multi Beam Echo sounder together with a Klein 4200 dual frequency Side Scan Sonar. A Cable Burial survey was carried out on the inshore 8km of the cable. The cable Buri- al survey was completed with an Innovatum Smartrak cable detection system following a tone applied to the cable. The Smartrak system was mounted on a Cougar XT ROV which was also used for the Video inspection element of the works. Surface positioning was provided by a C-NAV 3050 GNSS System and subsurface was provided by a Nexus Easytrak USBL system. A combination of QPS QINSy, Fledermaus, EIVA Navipac and Innovatum software was used for acquir- ing and processing the survey. The project was split into three phases to make the most of the MV FlatHolm?s unique capabilities to carry out all three elements of the scope of works. The Geotechnical investiga- tion was carried out rst ? comprising Vibrocores at each of the proposed anchor locations in Berth 4. The vessel was then switched to Geophysical mode to complete phase 2 - the full cable length bathymetric survey. Phase 3 comprised the ROV operations including the Visual and Cable Burial surveys. The biggest challenge to the project was the strong tidal streams on the site which restricted the window of operations for the ROV work. Using the more powerful Cougar XT was a bene t in being able to extend the window of operations. Shallow Water Operations G&D?s KVM Applied on Van Oord Pipelay Vessel Dutch Van Oord?s Þ rst shallow water pipe lay vessel?s infra- structure holds KVM hardware from German Guntermann & Drunck. KVM provides surveyor and chief of Þ cer in charge with the computer applications required for the process of laying pipes. A broad range of all sorts of equipment from cranes to welding stations, even a gym and accommodation for up to 300 people is what the Stingray crew calls home. The barge itself and its standard equipment were built in China, but was later tailored and converted by Van Oord who adjusted it to their individual needs of a shallow water pipe lay vessel. The Stingray is designed in accordance with the quality and safety standards in the oil and gas industry and equipped with state-of-the-art machinery to install pipelines from 6-60 inches in diameter. The interior of the vessel looks like a mass production site of motor vehicles. It?s a huge factory on sea. For Wave Hub, Coastline Surveys Completes Submarine Asset Survey November/December 201346 MTRMTR #9 (34-49).indd 46MTR #9 (34-49).indd 4612/13/2013 9:36:16 AM12/13/2013 9:36:16 AM

45

45

47

47