Page 54: of Marine Technology Magazine (September 2014)

Ocean Observation: Gliders, Buoys & Sub-Surface Networks

Read this page in Pdf, Flash or Html5 edition of September 2014 Marine Technology Magazine

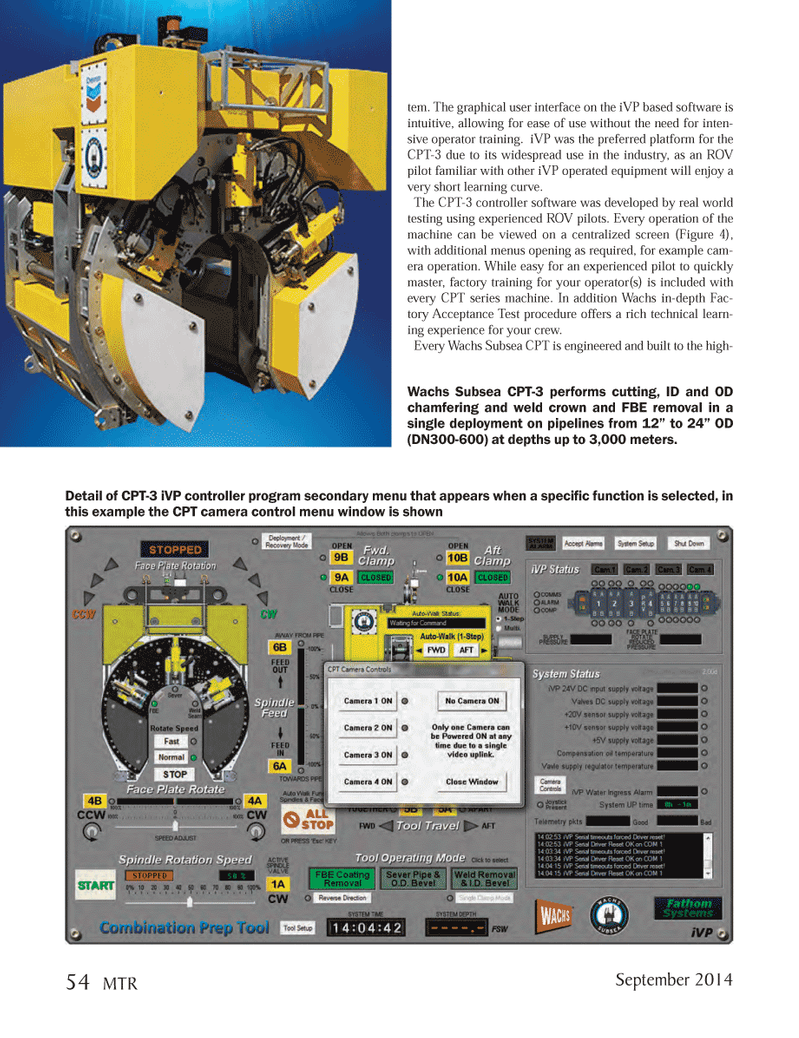

tem. The graphical user interface on the iVP based software is intuitive, allowing for ease of use without the need for inten- sive operator training. iVP was the preferred platform for the

CPT-3 due to its widespread use in the industry, as an ROV pilot familiar with other iVP operated equipment will enjoy a very short learning curve.

The CPT-3 controller software was developed by real world testing using experienced ROV pilots. Every operation of the machine can be viewed on a centralized screen (Figure 4), with additional menus opening as required, for example cam- era operation. While easy for an experienced pilot to quickly master, factory training for your operator(s) is included with every CPT series machine. In addition Wachs in-depth Fac- tory Acceptance Test procedure offers a rich technical learn- ing experience for your crew.

Every Wachs Subsea CPT is engineered and built to the high-

Detail of CPT-3 iVP controller program secondary menu that appears when a specifi c function is selected, in this example the CPT camera control menu window is shown

Wachs Subsea CPT-3 performs cutting, ID and OD chamfering and weld crown and FBE removal in a single deployment on pipelines from 12” to 24” OD (DN300-600) at depths up to 3,000 meters.

September 2014 54 MTR

MTR #7 (50-65).indd 54 8/27/2014 10:43:03 AM

53

53

55

55