Page 24: of Marine Technology Magazine (October 2014)

Subsea Defense

Read this page in Pdf, Flash or Html5 edition of October 2014 Marine Technology Magazine

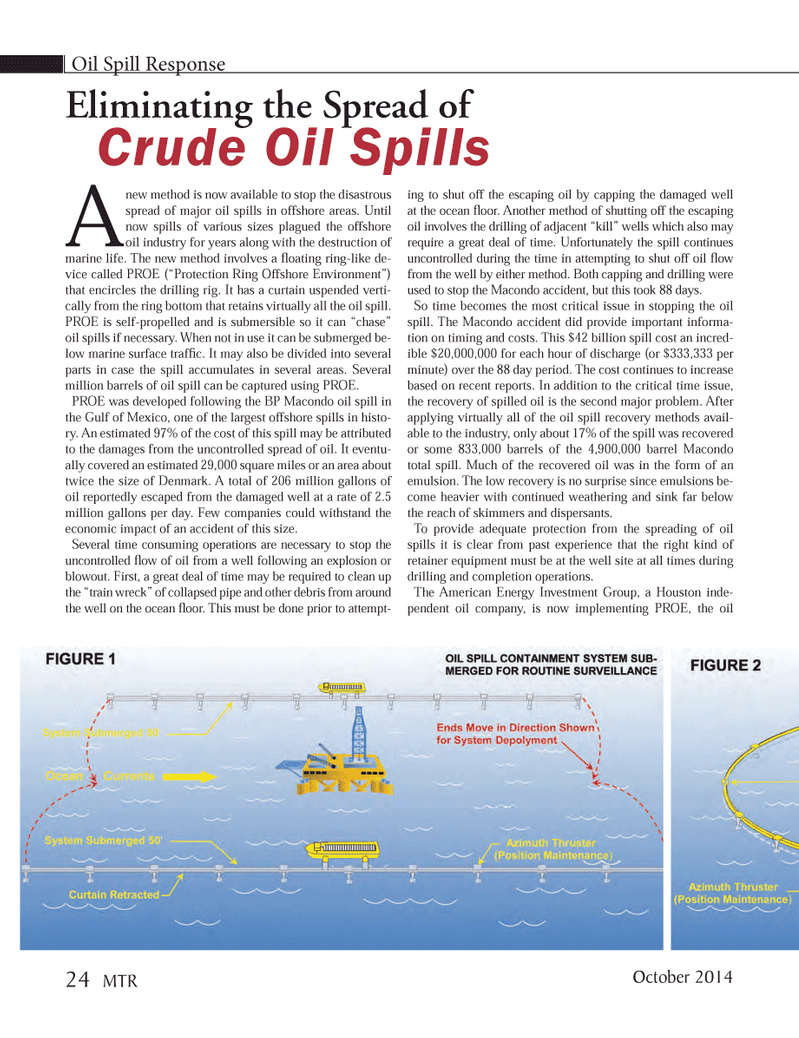

A new method is now available to stop the disastrous spread of major oil spills in offshore areas. Until now spills of various sizes plagued the offshore oil industry for years along with the destruction of marine life. The new method involves a ß oating ring-like de- vice called PROE (ÒProtection Ring Offshore EnvironmentÓ) that encircles the drilling rig. It has a curtain uspended verti- cally from the ring bottom that retains virtually all the oil spill. PROE is self-propelled and is submersible so it can ÒchaseÓ oil spills if necessary. When not in use it can be submerged be- low marine surface trafÞ c. It may also be divided into several parts in case the spill accumulates in several areas. Several million barrels of oil spill can be captured using PROE. PROE was developed following the BP Macondo oil spill in the Gulf of Mexico, one of the largest offshore spills in histo- ry. An estimated 97% of the cost of this spill may be attributed to the damages from the uncontrolled spread of oil. It eventu- ally covered an estimated 29,000 square miles or an area about twice the size of Denmark. A total of 206 million gallons of oil reportedly escaped from the damaged well at a rate of 2.5 million gallons per day. Few companies could withstand the economic impact of an accident of this size.Several time consuming operations are necessary to stop the uncontrolled ß ow of oil from a well following an explosion or blowout. First, a great deal of time may be required to clean up the Òtrain wreckÓ of collapsed pipe and other debris from around the well on the ocean ß oor. This must be done prior to attempt- ing to shut off the escaping oil by capping the damaged well at the ocean ß oor. Another method of shutting off the escaping oil involves the drilling of adjacent ÒkillÓ wells which also may require a great deal of time. Unfortunately the spill continues uncontrolled during the time in attempting to shut off oil ß ow from the well by either method. Both capping and drilling were used to stop the Macondo accident, but this took 88 days. So time becomes the most critical issue in stopping the oil spill. The Macondo accident did provide important informa- tion on timing and costs. This $42 billion spill cost an incred- ible $20,000,000 for each hour of discharge (or $333,333 per minute) over the 88 day period. The cost continues to increase based on recent reports. In addition to the critical time issue, the recovery of spilled oil is the second major problem. After applying virtually all of the oil spill recovery methods avail- able to the industry, only about 17% of the spill was recovered or some 833,000 barrels of the 4,900,000 barrel Macondo total spill. Much of the recovered oil was in the form of an emulsion. The low recovery is no surprise since emulsions be- come heavier with continued weathering and sink far below the reach of skimmers and dispersants. To provide adequate protection from the spreading of oil spills it is clear from past experience that the right kind of retainer equipment must be at the well site at all times during drilling and completion operations.The American Energy Investment Group, a Houston inde- pendent oil company, is now implementing PROE, the oil Oil Spill Response Eliminating the Spread of Crude Oil Spills24 MTROctober 2014MTR #8 (18-33).indd 24MTR #8 (18-33).indd 2410/10/2014 1:49:20 PM10/10/2014 1:49:20 PM

23

23

25

25