Page 22: of Marine Technology Magazine (November 2015)

Read this page in Pdf, Flash or Html5 edition of November 2015 Marine Technology Magazine

Case Studies

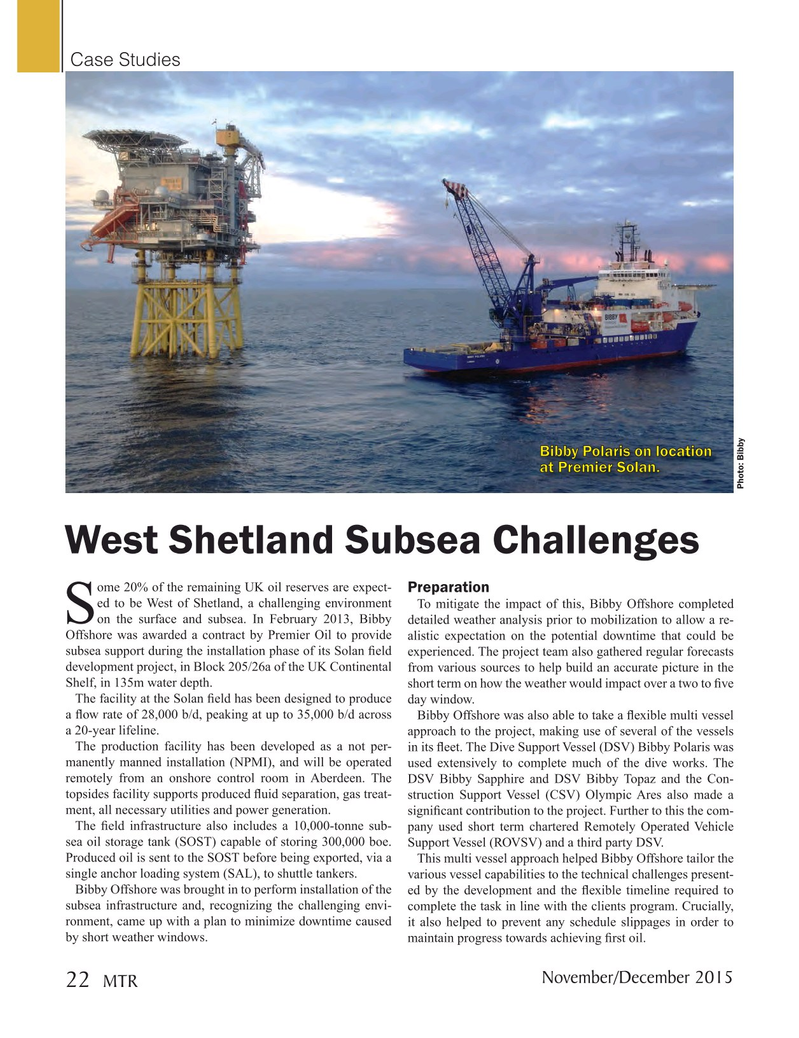

Bibby Polaris on location at Premier Solan.

Photo: Bibby

West Shetland Subsea Challenges ome 20% of the remaining UK oil reserves are expect-

Preparation ed to be West of Shetland, a challenging environment To mitigate the impact of this, Bibby Offshore completed

Son the surface and subsea. In February 2013, Bibby detailed weather analysis prior to mobilization to allow a re-

Offshore was awarded a contract by Premier Oil to provide alistic expectation on the potential downtime that could be subsea support during the installation phase of its Solan ? eld experienced. The project team also gathered regular forecasts development project, in Block 205/26a of the UK Continental from various sources to help build an accurate picture in the

Shelf, in 135m water depth. short term on how the weather would impact over a two to ? ve

The facility at the Solan ? eld has been designed to produce day window.

a ? ow rate of 28,000 b/d, peaking at up to 35,000 b/d across Bibby Offshore was also able to take a ? exible multi vessel a 20-year lifeline. approach to the project, making use of several of the vessels

The production facility has been developed as a not per- in its ? eet. The Dive Support Vessel (DSV) Bibby Polaris was manently manned installation (NPMI), and will be operated used extensively to complete much of the dive works. The remotely from an onshore control room in Aberdeen. The DSV Bibby Sapphire and DSV Bibby Topaz and the Con- topsides facility supports produced ? uid separation, gas treat- struction Support Vessel (CSV) Olympic Ares also made a ment, all necessary utilities and power generation. signi? cant contribution to the project. Further to this the com-

The ? eld infrastructure also includes a 10,000-tonne sub- pany used short term chartered Remotely Operated Vehicle sea oil storage tank (SOST) capable of storing 300,000 boe. Support Vessel (ROVSV) and a third party DSV.

Produced oil is sent to the SOST before being exported, via a This multi vessel approach helped Bibby Offshore tailor the single anchor loading system (SAL), to shuttle tankers. various vessel capabilities to the technical challenges present-

Bibby Offshore was brought in to perform installation of the ed by the development and the ? exible timeline required to subsea infrastructure and, recognizing the challenging envi- complete the task in line with the clients program. Crucially, ronment, came up with a plan to minimize downtime caused it also helped to prevent any schedule slippages in order to by short weather windows. maintain progress towards achieving ? rst oil.

November/December 2015 22 MTR

MTR #9 (18-33).indd 22 12/8/2015 10:25:50 AM

21

21

23

23