Page 65: of Marine Technology Magazine (July 2016)

MTR 100: The 11th Annual Listing of 100 Leading Subsea Companies

Read this page in Pdf, Flash or Html5 edition of July 2016 Marine Technology Magazine

Hydroid 6 Benjamin Nye Circle, Pocasset, MA 02559

Phone: 508-563-6565

Fax: 508-563-3445

Email: [email protected]

Website: http://www.hydroid.com

CEO/President: Duane Fotheringham

Number of Employees: 162

President: Duane Fotheringham

Marketing Director: Graham Lester

Engineering Director: Sandor Becz

Facility: • 40,000-square-foot state-of-the-art facility – opened October 2014 • An additional 15,000 square foot building is cur- rently being built. Opening is planned for end of (Photo: Eric Haun) 2016.

Square Footage: 40,000-square-feet

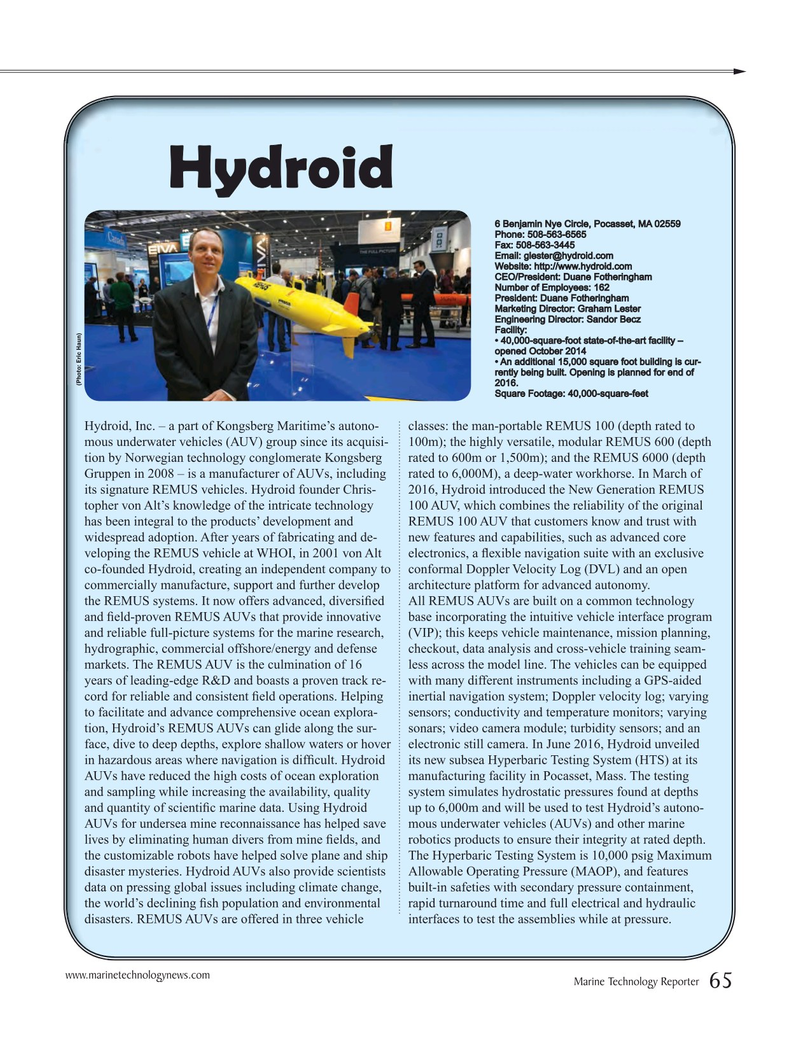

Hydroid, Inc. – a part of Kongsberg Maritime’s autono- classes: the man-portable REMUS 100 (depth rated to mous underwater vehicles (AUV) group since its acquisi- 100m); the highly versatile, modular REMUS 600 (depth tion by Norwegian technology conglomerate Kongsberg rated to 600m or 1,500m); and the REMUS 6000 (depth

Gruppen in 2008 – is a manufacturer of AUVs, including rated to 6,000M), a deep-water workhorse. In March of its signature REMUS vehicles. Hydroid founder Chris- 2016, Hydroid introduced the New Generation REMUS topher von Alt’s knowledge of the intricate technology 100 AUV, which combines the reliability of the original has been integral to the products’ development and REMUS 100 AUV that customers know and trust with widespread adoption. After years of fabricating and de- new features and capabilities, such as advanced core veloping the REMUS vehicle at WHOI, in 2001 von Alt electronics, a ? exible navigation suite with an exclusive co-founded Hydroid, creating an independent company to conformal Doppler Velocity Log (DVL) and an open commercially manufacture, support and further develop architecture platform for advanced autonomy.

the REMUS systems. It now offers advanced, diversi? ed All REMUS AUVs are built on a common technology and ? eld-proven REMUS AUVs that provide innovative base incorporating the intuitive vehicle interface program and reliable full-picture systems for the marine research, (VIP); this keeps vehicle maintenance, mission planning, hydrographic, commercial offshore/energy and defense checkout, data analysis and cross-vehicle training seam- markets. The REMUS AUV is the culmination of 16 less across the model line. The vehicles can be equipped years of leading-edge R&D and boasts a proven track re- with many different instruments including a GPS-aided cord for reliable and consistent ? eld operations. Helping inertial navigation system; Doppler velocity log; varying to facilitate and advance comprehensive ocean explora- sensors; conductivity and temperature monitors; varying tion, Hydroid’s REMUS AUVs can glide along the sur- sonars; video camera module; turbidity sensors; and an face, dive to deep depths, explore shallow waters or hover electronic still camera. In June 2016, Hydroid unveiled in hazardous areas where navigation is dif? cult. Hydroid its new subsea Hyperbaric Testing System (HTS) at its

AUVs have reduced the high costs of ocean exploration manufacturing facility in Pocasset, Mass. The testing and sampling while increasing the availability, quality system simulates hydrostatic pressures found at depths and quantity of scienti? c marine data. Using Hydroid up to 6,000m and will be used to test Hydroid’s autono-

AUVs for undersea mine reconnaissance has helped save mous underwater vehicles (AUVs) and other marine lives by eliminating human divers from mine ? elds, and robotics products to ensure their integrity at rated depth. the customizable robots have helped solve plane and ship The Hyperbaric Testing System is 10,000 psig Maximum disaster mysteries. Hydroid AUVs also provide scientists Allowable Operating Pressure (MAOP), and features data on pressing global issues including climate change, built-in safeties with secondary pressure containment, the world’s declining ? sh population and environmental rapid turnaround time and full electrical and hydraulic disasters. REMUS AUVs are offered in three vehicle interfaces to test the assemblies while at pressure. www.marinetechnologynews.com

Marine Technology Reporter 65

MTR #6 (50-65).indd 65 7/28/2016 9:07:38 AM

64

64

66

66