Page 61: of Marine Technology Magazine (October 2016)

AUV Operations

Read this page in Pdf, Flash or Html5 edition of October 2016 Marine Technology Magazine

New Tech for

Biscay Marine

Energy Pa rk

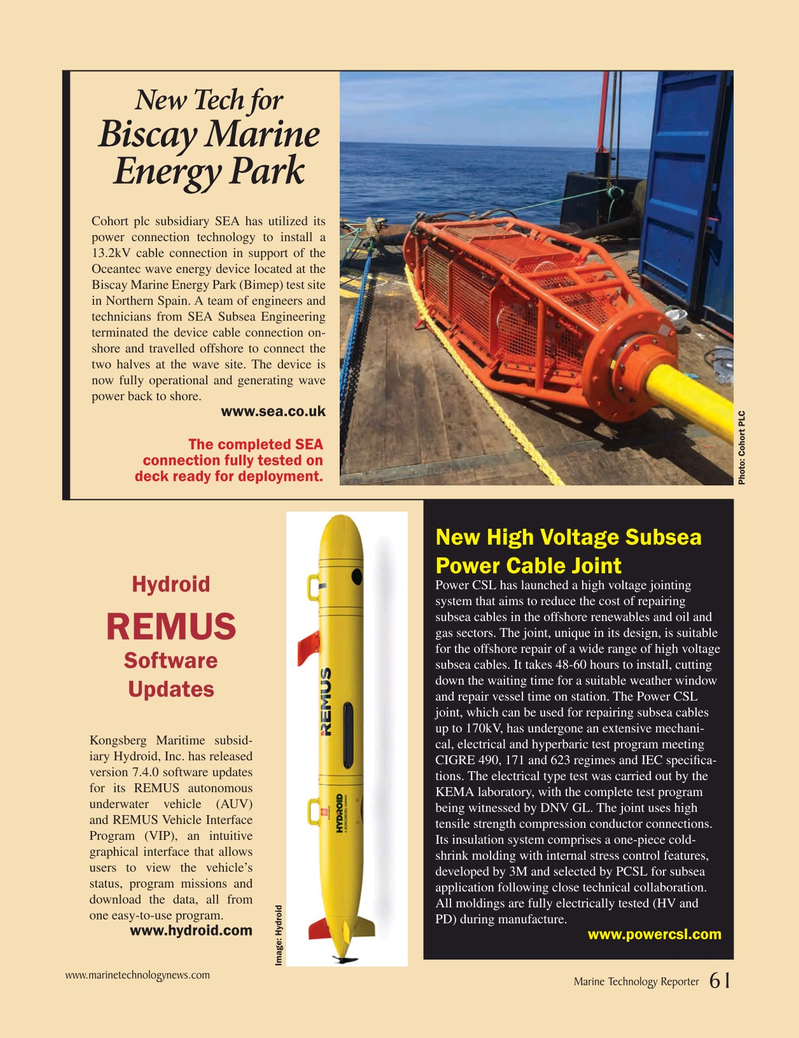

Cohort plc subsidiary SEA has utilized its power connection technology to install a 13.2kV cable connection in support of the

Oceantec wave energy device located at the

Biscay Marine Energy Park (Bimep) test site in Northern Spain. A team of engineers and technicians from SEA Subsea Engineering terminated the device cable connection on- shore and travelled offshore to connect the two halves at the wave site. The device is now fully operational and generating wave power back to shore. www.sea.co.uk

The completed SEA connection fully tested on deck ready for deployment.

Photo: Cohort PLC

New High Voltage Subsea

Power Cable Joint

Power CSL has launched a high voltage jointing

Hydroid system that aims to reduce the cost of repairing subsea cables in the offshore renewables and oil and gas sectors. The joint, unique in its design, is suitable

REMUS for the offshore repair of a wide range of high voltage

Software subsea cables. It takes 48-60 hours to install, cutting down the waiting time for a suitable weather window

Updates and repair vessel time on station. The Power CSL joint, which can be used for repairing subsea cables up to 170kV, has undergone an extensive mechani-

Kongsberg Maritime subsid- cal, electrical and hyperbaric test program meeting iary Hydroid, Inc. has released

CIGRE 490, 171 and 623 regimes and IEC speci? ca- version 7.4.0 software updates tions. The electrical type test was carried out by the for its REMUS autonomous

KEMA laboratory, with the complete test program underwater vehicle (AUV) being witnessed by DNV GL. The joint uses high and REMUS Vehicle Interface tensile strength compression conductor connections.

Program (VIP), an intuitive

Its insulation system comprises a one-piece cold- graphical interface that allows shrink molding with internal stress control features, users to view the vehicle’s developed by 3M and selected by PCSL for subsea status, program missions and application following close technical collaboration. download the data, all from

All moldings are fully electrically tested (HV and one easy-to-use program.

PD) during manufacture.

www.hydroid.com www.powercsl.com

Image: Hydroid www.marinetechnologynews.com

Marine Technology Reporter 61

MTR #8 (50-64).indd 61 9/28/2016 9:53:40 AM

60

60

62

62