Page 50: of Marine Technology Magazine (June 2019)

Hydrographic Survey: Single & Multibeam Sonar

Read this page in Pdf, Flash or Html5 edition of June 2019 Marine Technology Magazine

Research Institutions and enable in-situ analysis of marine water samples. Using communications capability during trials out of Genoa port micro? uidic analysis means smaller samples for analysis are in July 2018. The next stages are more robust testing on the needed and therefore less and weaker reagent, enabling lon- automatic prototype, including more extensive testing with ger duration monitoring missions, in turn allowing greater real water samples. areas to be covered. More could also be done with this device, says Periolatto.

First, the group set out to optimize the way samples are Integrating the laser source and detection technologies, a analyzed and the laser source (different sources were used micro? uidic system to collect the samples and ? lter them, for chromium and zinc detection) for the spectrophotomet- and using microelectronic systems, meant an otherwise lab- ric analysis. This in fact resulted in a much simpler process oratory-based process could be packed into a cylinder for than was previously used, says Periolatto. The work also integration on to an AUV. “We are planning to investigate tested what the system could detect, to make sure it would other metals detection but also other contaminants such as be ? t for purpose. Using the lab-on-a-chip technology meant nanoplastics or aromatic compounds,” she told OE.

the sample size required was just 1ml, which is enough for Using different chambers in the micro? uid system can also measurement to a detection of 5 ppb for chromium. “The mean that different materials analysis could be done, says amount of treated sample traditionally put in the cuvette is Periolatto. By building the device in a modular way, as well 5-10ml, but it requires the treatment of at least 50-100ml of as automating the process, this means the choice of metal sample,” Periolatto told MTR. The lab on a chip developed being detected could be controlled via remote control using was 150mm-long, allowing an optical path of 100mm to de- the vehicle’s onboard wireless communication. tect metal concentrations of few ppb, and 80mm width, that The project was also supported by the Italian Direzione is four channels with diameter 2mm each. The whole ap- Generale per la Sicurezza anche ambientale delle attività paratus for sampling, sample treatment, degasing and waste minerarie ed energetiche (DGS UNIMG), del Ministero discharge is ? xed on a plate measuring 100mm by 330mm. dello Sviluppo Economico (MISE) as well as Microla Op-

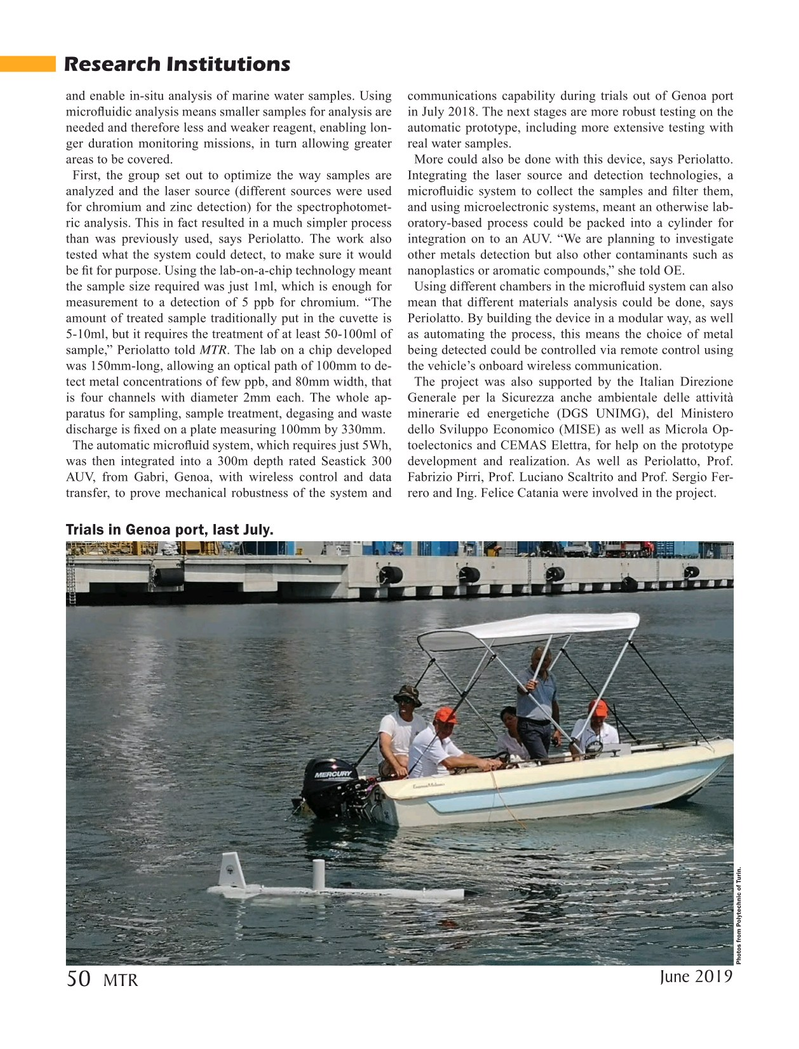

The automatic micro? uid system, which requires just 5Wh, toelectonics and CEMAS Elettra, for help on the prototype was then integrated into a 300m depth rated Seastick 300 development and realization. As well as Periolatto, Prof.

AUV, from Gabri, Genoa, with wireless control and data Fabrizio Pirri, Prof. Luciano Scaltrito and Prof. Sergio Fer- transfer, to prove mechanical robustness of the system and rero and Ing. Felice Catania were involved in the project.

Trials in Genoa port, last July.

Photos from Polytechnic of Turin.

June 2019 50

MTR

MTR #5 (50-63).indd 50 5/28/2019 9:47:17 AM

49

49

51

51