Page 32: of Marine Technology Magazine (October 2019)

Ocean Observation: Gliders, Buoys & Sub-Surface Networks

Read this page in Pdf, Flash or Html5 edition of October 2019 Marine Technology Magazine

Higher Learning: SINTEF led to advanced medical sensor development and an expanded trometry techniques,” one of a preponderance of foreign-born lab offering for health industry and materials development, researchers says of the materials science at SINTEF. Comple- two areas of science only very recently associated with Nor- mentary facilities include a coating laboratory and ? eld test- way. SINTEF now drives and quali? es advances in materials ing understood to have been availed by the likes of coatings characterization and coatings technology. One obvious ad- giant Jotun for the award-winning antifouling and other sur- vance is that Norwegian subsea cables and subsea equipment facing products that meet numerous ISO standards tested for bear a characteristic quality look. Labs in these and related at SINTEF. Ice-resistant coatings are now being tested.

segments include a throughput lab that uses dosing robots and But, it’s in oil and gas that SINTEF researchers cover the pressure chambers to come up with “? uid transport” solutions gamut of Norwegian offshore energy value-creation. With the for a variety of new and up-and-coming processes in industry potential rewards high, spin-offs from oil and gas research and oil and gas. Among the non-offshore advances are special have been many and stem from research into drilling and well tubes and assemblies for Norway’s nascent automotive sector. control; exploration and production; gas-process tech; in- creased oil recovery; plug and abandonment; re? ning; safety

Standards testing and the environment; subsea systems and pipeline transport.

At all SINTEF labs, the technology at researchers’ disposal The modern Norwegian oil and gas industry is likely most seems topnotch. The advanced materials lab in Oslo employs in debt to SINTEF for the multiphase ? ow laboratory, and modeling and supercomputer infrastructure called SIGMA2, all its offshoots, where R&D tested new ways to handle well or the national infrastructure for computational science. Re- stream and get downhole tools, subsea and topside equipment searchers use supercomputing and microscopy to determine into service. Some say it was here that Norway’s decades old the molecular responses of materials being lab-tested. pump makers “scaled up” to produce space-age, valve-dense “We utilize a range of microscopy, spectroscopy and spec- tools to get the most oil and gas out of offshore reservoirs.

Flow assurance has been key. SINTEF expertise helped en- gineer the removal of things like frosted hydrates (or slugs) from gas and oil on its way to ? nal processing. Decades of re-

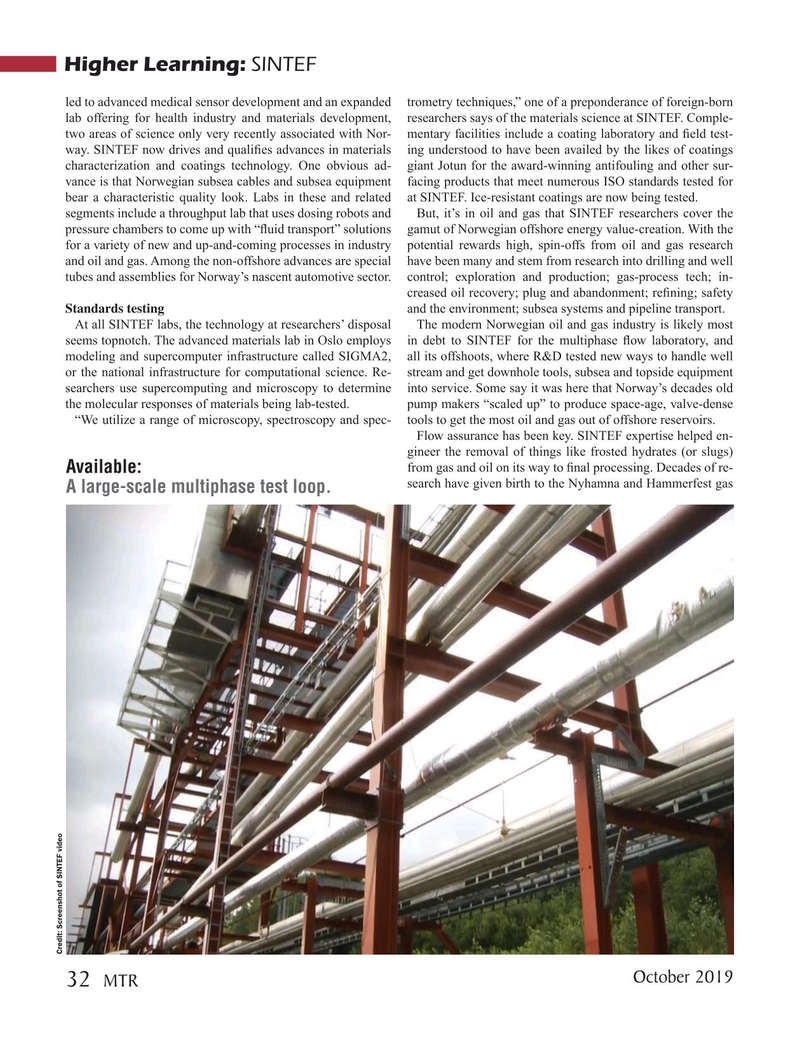

Available: search have given birth to the Nyhamna and Hammerfest gas

A large-scale multiphase test loop.

Credit: Screenshot of SINTEF video

October 2019 32 MTR

MTR #8 (18-33).indd 32 10/8/2019 10:06:36 AM

31

31

33

33