Page 58: of Marine Technology Magazine (June 2020)

Read this page in Pdf, Flash or Html5 edition of June 2020 Marine Technology Magazine

Tech Files

Innovative products, technologies and concepts

Subsea Clamping Cylinder

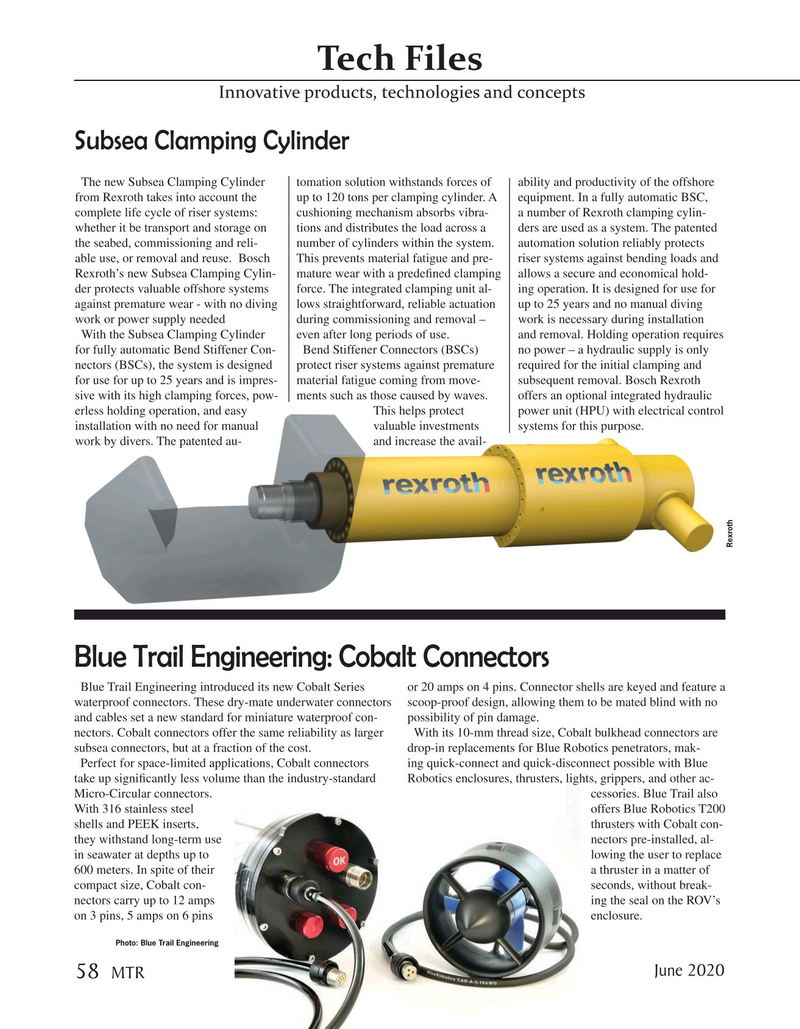

The new Subsea Clamping Cylinder tomation solution withstands forces of ability and productivity of the offshore from Rexroth takes into account the up to 120 tons per clamping cylinder. A equipment. In a fully automatic BSC, complete life cycle of riser systems: cushioning mechanism absorbs vibra- a number of Rexroth clamping cylin- whether it be transport and storage on tions and distributes the load across a ders are used as a system. The patented the seabed, commissioning and reli- number of cylinders within the system. automation solution reliably protects able use, or removal and reuse. Bosch This prevents material fatigue and pre- riser systems against bending loads and

Rexroth’s new Subsea Clamping Cylin- mature wear with a predefned clamping allows a secure and economical hold- der protects valuable offshore systems force. The integrated clamping unit al- ing operation. It is designed for use for against premature wear - with no diving lows straightforward, reliable actuation up to 25 years and no manual diving work or power supply needed during commissioning and removal – work is necessary during installation

With the Subsea Clamping Cylinder even after long periods of use. and removal. Holding operation requires for fully automatic Bend Stiffener Con- Bend Stiffener Connectors (BSCs) no power – a hydraulic supply is only nectors (BSCs), the system is designed protect riser systems against premature required for the initial clamping and for use for up to 25 years and is impres- material fatigue coming from move- subsequent removal. Bosch Rexroth sive with its high clamping forces, pow- ments such as those caused by waves. offers an optional integrated hydraulic erless holding operation, and easy This helps protect power unit (HPU) with electrical control installation with no need for manual valuable investments systems for this purpose.

work by divers. The patented au- and increase the avail-

Rexroth

Blue Trail Engineering: Cobalt Connectors

Blue Trail Engineering introduced its new Cobalt Series or 20 amps on 4 pins. Connector shells are keyed and feature a waterproof connectors. These dry-mate underwater connectors scoop-proof design, allowing them to be mated blind with no and cables set a new standard for miniature waterproof con- possibility of pin damage.

nectors. Cobalt connectors offer the same reliability as larger With its 10-mm thread size, Cobalt bulkhead connectors are subsea connectors, but at a fraction of the cost. drop-in replacements for Blue Robotics penetrators, mak-

Perfect for space-limited applications, Cobalt connectors ing quick-connect and quick-disconnect possible with Blue take up signifcantly less volume than the industry-standard Robotics enclosures, thrusters, lights, grippers, and other ac-

Micro-Circular connectors. cessories. Blue Trail also

With 316 stainless steel offers Blue Robotics T200 shells and PEEK inserts, thrusters with Cobalt con- they withstand long-term use nectors pre-installed, al- in seawater at depths up to lowing the user to replace 600 meters. In spite of their a thruster in a matter of compact size, Cobalt con- seconds, without break- nectors carry up to 12 amps ing the seal on the ROV’s on 3 pins, 5 amps on 6 pins enclosure.

Photo: Blue Trail Engineering

June 2020 58

MTR

57

57

59

59