Page 58: of Marine Technology Magazine (July 2021)

Autonomous Vehicle Operations

Read this page in Pdf, Flash or Html5 edition of July 2021 Marine Technology Magazine

Tech File

Innovative new products, technologies and concepts

Live Streaming Ocean

Exploration via BlueComm

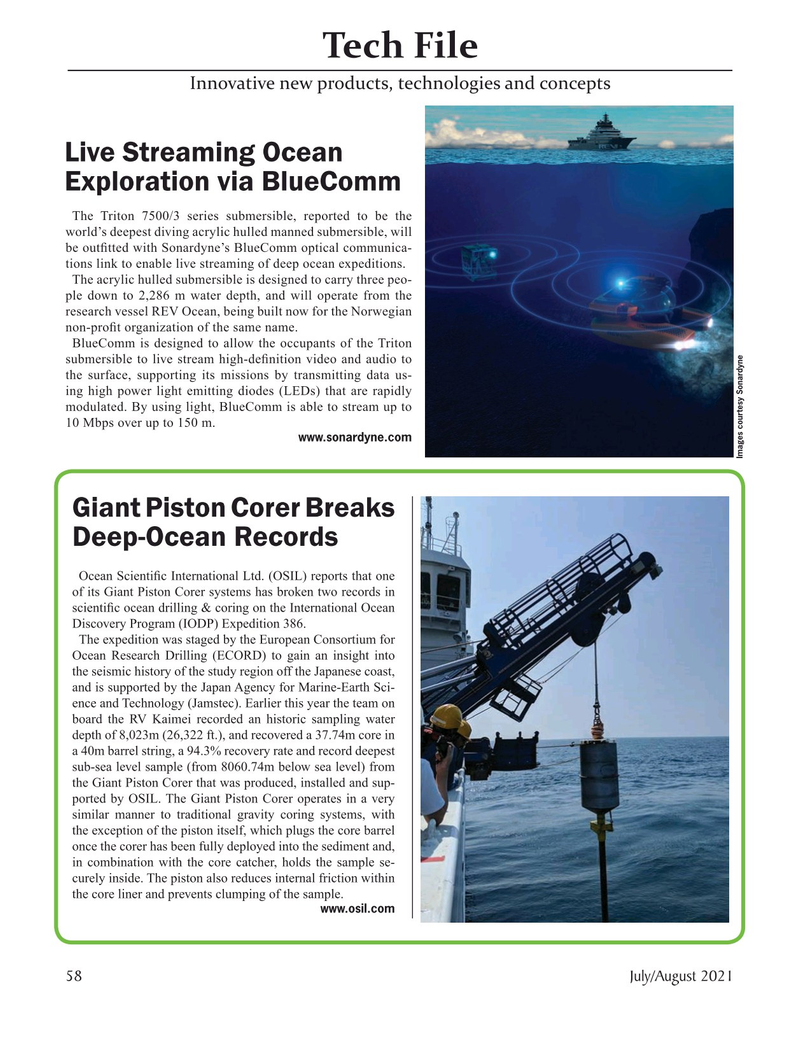

The Triton 7500/3 series submersible, reported to be the world’s deepest diving acrylic hulled manned submersible, will be out? tted with Sonardyne’s BlueComm optical communica- tions link to enable live streaming of deep ocean expeditions.

The acrylic hulled submersible is designed to carry three peo- ple down to 2,286 m water depth, and will operate from the research vessel REV Ocean, being built now for the Norwegian non-pro? t organization of the same name.

BlueComm is designed to allow the occupants of the Triton submersible to live stream high-de? nition video and audio to the surface, supporting its missions by transmitting data us- ing high power light emitting diodes (LEDs) that are rapidly modulated. By using light, BlueComm is able to stream up to 10 Mbps over up to 150 m.

www.sonardyne.com

Images courtesy Sonardyne

Giant Piston Corer Breaks

Deep-Ocean Records

Ocean Scienti? c International Ltd. (OSIL) reports that one of its Giant Piston Corer systems has broken two records in scienti? c ocean drilling & coring on the International Ocean

Discovery Program (IODP) Expedition 386.

The expedition was staged by the European Consortium for

Ocean Research Drilling (ECORD) to gain an insight into the seismic history of the study region off the Japanese coast, and is supported by the Japan Agency for Marine-Earth Sci- ence and Technology (Jamstec). Earlier this year the team on board the RV Kaimei recorded an historic sampling water depth of 8,023m (26,322 ft.), and recovered a 37.74m core in a 40m barrel string, a 94.3% recovery rate and record deepest sub-sea level sample (from 8060.74m below sea level) from the Giant Piston Corer that was produced, installed and sup- ported by OSIL. The Giant Piston Corer operates in a very similar manner to traditional gravity coring systems, with the exception of the piston itself, which plugs the core barrel once the corer has been fully deployed into the sediment and, in combination with the core catcher, holds the sample se- curely inside. The piston also reduces internal friction within the core liner and prevents clumping of the sample.

www.osil.com 58 July/August 2021

MTR #5 (50-63).indd 58 7/30/2021 9:47:26 AM

57

57

59

59