Page 14: of Marine Technology Magazine (July 2023)

Read this page in Pdf, Flash or Html5 edition of July 2023 Marine Technology Magazine

LANDER LAB #8 TITANIUM AND OCEAN LANDERS

TITANIUM

AND

OCEAN

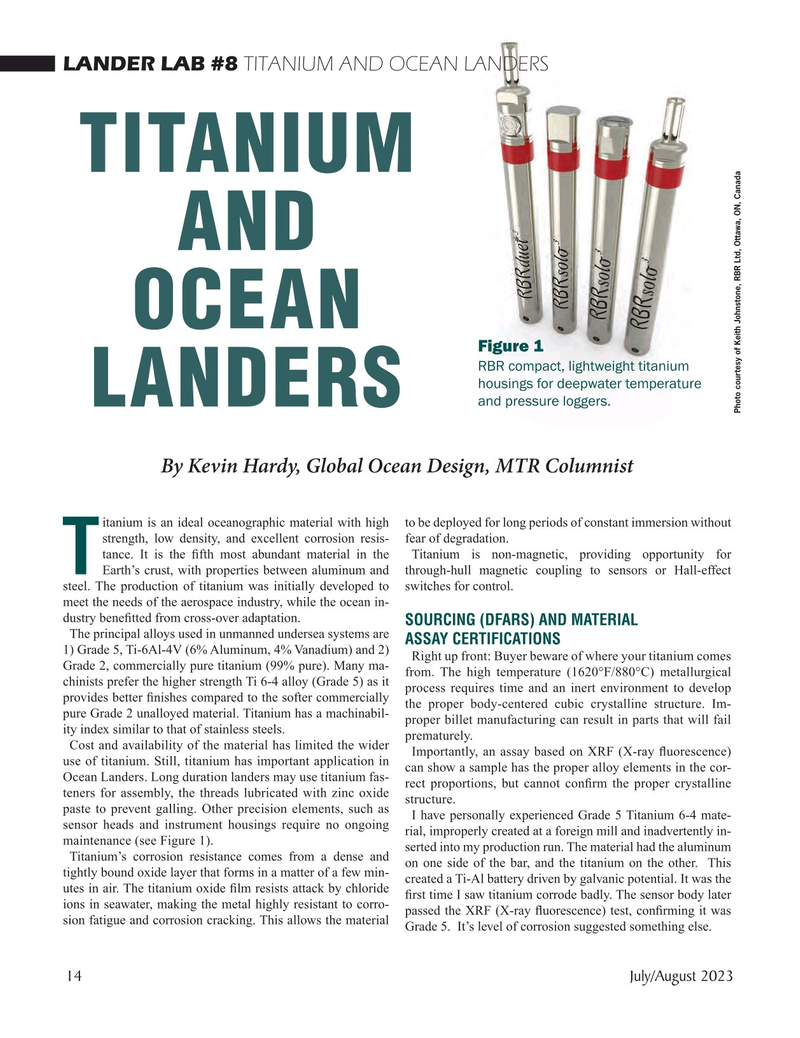

Figure 1

RBR compact, lightweight titanium housings for deepwater temperature and pressure loggers.

LANDERS

Photo courtesy of Keith Johnstone, RBR Ltd, Ottawa, ON, Canada

By Kevin Hardy, Global Ocean Design, MTR Columnist itanium is an ideal oceanographic material with high to be deployed for long periods of constant immersion without strength, low density, and excellent corrosion resis- fear of degradation.

tance. It is the ? fth most abundant material in the Titanium is non-magnetic, providing opportunity for

T Earth’s crust, with properties between aluminum and through-hull magnetic coupling to sensors or Hall-effect steel. The production of titanium was initially developed to switches for control.

meet the needs of the aerospace industry, while the ocean in- dustry bene? tted from cross-over adaptation.

SOURCING (DFARS) AND MATERIAL

The principal alloys used in unmanned undersea systems are

ASSAY CERTIFICATIONS 1) Grade 5, Ti-6Al-4V (6% Aluminum, 4% Vanadium) and 2)

Right up front: Buyer beware of where your titanium comes

Grade 2, commercially pure titanium (99% pure). Many ma- from. The high temperature (1620°F/880°C) metallurgical chinists prefer the higher strength Ti 6-4 alloy (Grade 5) as it process requires time and an inert environment to develop provides better ? nishes compared to the softer commercially the proper body-centered cubic crystalline structure. Im- pure Grade 2 unalloyed material. Titanium has a machinabil- proper billet manufacturing can result in parts that will fail ity index similar to that of stainless steels. prematurely.

Cost and availability of the material has limited the wider

Importantly, an assay based on XRF (X-ray ? uorescence) use of titanium. Still, titanium has important application in can show a sample has the proper alloy elements in the cor-

Ocean Landers. Long duration landers may use titanium fas- rect proportions, but cannot con? rm the proper crystalline teners for assembly, the threads lubricated with zinc oxide structure.

paste to prevent galling. Other precision elements, such as

I have personally experienced Grade 5 Titanium 6-4 mate- sensor heads and instrument housings require no ongoing rial, improperly created at a foreign mill and inadvertently in- maintenance (see Figure 1).

serted into my production run. The material had the aluminum

Titanium’s corrosion resistance comes from a dense and on one side of the bar, and the titanium on the other. This tightly bound oxide layer that forms in a matter of a few min- created a Ti-Al battery driven by galvanic potential. It was the utes in air. The titanium oxide ? lm resists attack by chloride ? rst time I saw titanium corrode badly. The sensor body later ions in seawater, making the metal highly resistant to corro- passed the XRF (X-ray ? uorescence) test, con? rming it was sion fatigue and corrosion cracking. This allows the material

Grade 5. It’s level of corrosion suggested something else.

14 July/August 2023

MTR #5 (1-17).indd 14 7/20/2023 9:05:56 AM

13

13

15

15