Page 18: of Marine Technology Magazine (March 2024)

Read this page in Pdf, Flash or Html5 edition of March 2024 Marine Technology Magazine

TECH FEATURE IMR

There are also weaknesses in terms of accuracy because of FiGS Operations and Bene? ts signal noise and the ability to detect small ? eld gradients. In Conventional approaches to evaluating cathodic protection this process there is a risk that possible issues like coating (CP) systems offer only a momentary glimpse into their sta- damages are not discovered. This can happen because some tus. This limitation compels operators to schedule CP inspec- of the signal peaks are interpreted as noise instead of being tions at predetermined intervals, typically every three to ? ve picked up as coating damage. years, or to conduct CP assessments opportunistically when

In contrast, a new generation high sensitivity ? eld gradi- in the vicinity. FiGS, however, revolutionizes this process by ent sensor for use on ROVs and AUVs developed by FORCE providing detailed insights into the lifespan of the CP system.

Technology employs a novel approach with its electrodes This capability enables operators to tailor survey schedules mounted on a rotating head. Called FiGS, the design effec- more effectively, basing them on the residual life of the an- tively counters the issue of cell drift and the need for calibra- odes, thereby optimizing the frequency of inspections and re- tion. Moreover, the rotating mechanism enables the sensor to ducing maintenance costs.

determine the direction of the electric ? eld. This directional The system can also collect data faster than other measure- insight not only provides a relative positioning for the ? nd- ment methods. A FiGS pipeline survey can be conducted with ings but also ensures that the sensor’s readings are consistent, an ROV ? ying at a speed up to 6-8 km/h without losing valu- irrespective of the varying positions of the ROV during the able information. This is faster than any other advanced CP survey. inspection tool on the market. FiGS can also be positioned

FiGS technology integrates ? eld gradient detection with higher above the pipeline and still obtain valuable data. The the measurement of protection levels (potential) using non- increased speed saves costly vessel time, while the larger mea- contact sensors. The collected data is then merged with CP surement distance lowers the risks associated with the ? ight modeling to provide a comprehensive analysis. This analysis of the ROV. includes accurate predictions of the asset’s lifespan, anode Crucially, the system can be used on buried, trenched or rock current output, and a potential pro? le, offering a more ef? - dumped pipelines, obtaining the same information as for an cient and thorough assessment of maritime structures’ protec- exposed pipeline. It integrates with active pipe trackers (e.g., tion against corrosion than possible with stab surveys or dual TSS440) as the signals from the tracker do not affect the sen- cell ? eld gradient surveys. sor readings. This feature reduces offshore time as a pre-sur-

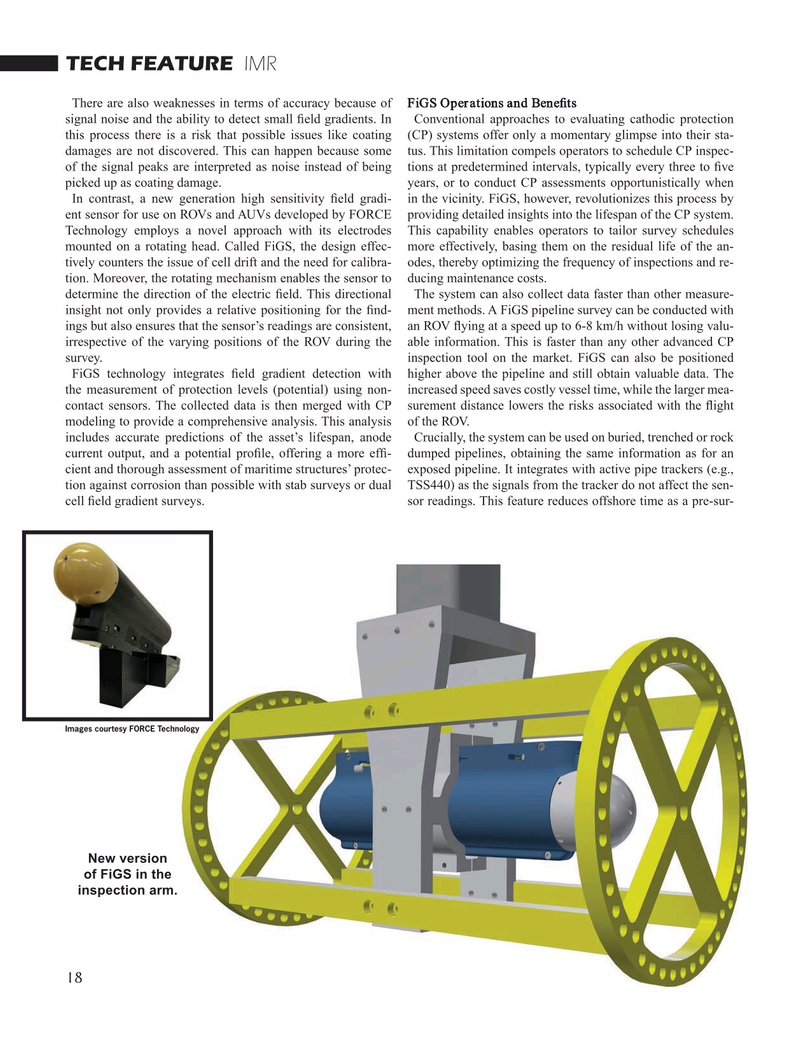

Images courtesy FORCE Technology

New version of FiGS in the inspection arm.

18

MTR #3 (18-33).indd 18 4/4/2024 8:59:50 AM

17

17

19

19