Page 22: of Marine Technology Magazine (September 2024)

Read this page in Pdf, Flash or Html5 edition of September 2024 Marine Technology Magazine

MTR 100

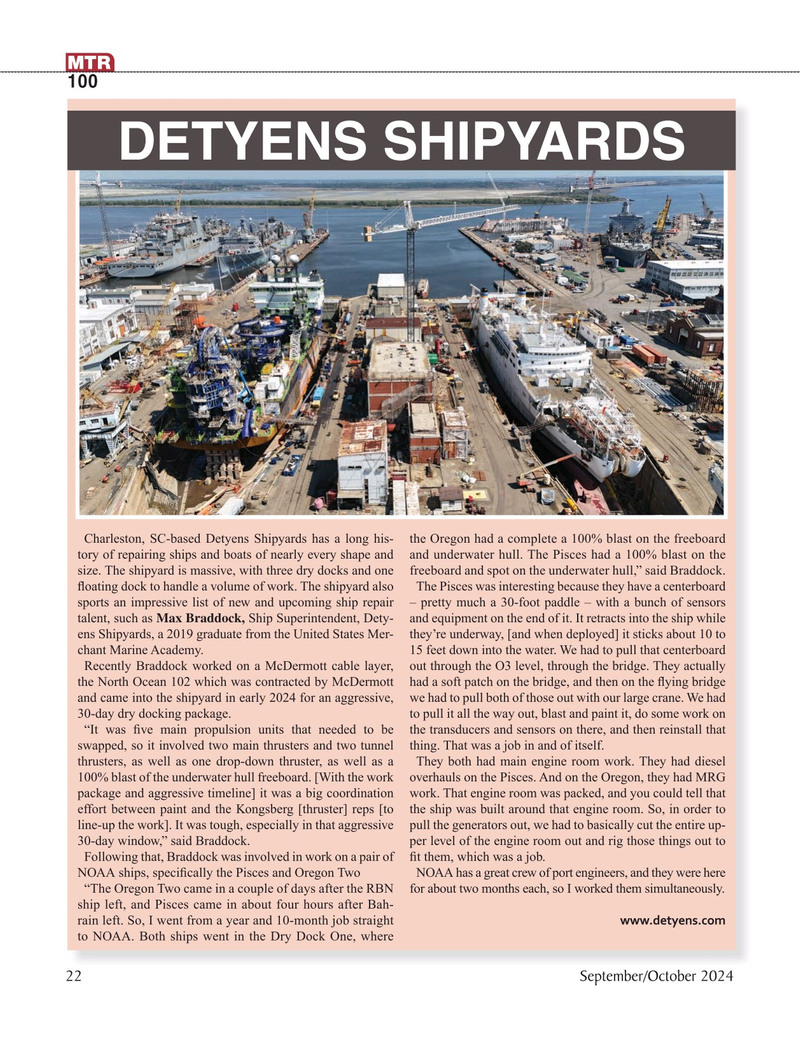

DETYENS SHIPYARDS

Charleston, SC-based Detyens Shipyards has a long his- the Oregon had a complete a 100% blast on the freeboard tory of repairing ships and boats of nearly every shape and and underwater hull. The Pisces had a 100% blast on the size. The shipyard is massive, with three dry docks and one freeboard and spot on the underwater hull,” said Braddock.

? oating dock to handle a volume of work. The shipyard also The Pisces was interesting because they have a centerboard sports an impressive list of new and upcoming ship repair – pretty much a 30-foot paddle – with a bunch of sensors talent, such as Max Braddock, Ship Superintendent, Dety- and equipment on the end of it. It retracts into the ship while ens Shipyards, a 2019 graduate from the United States Mer- they’re underway, [and when deployed] it sticks about 10 to chant Marine Academy. 15 feet down into the water. We had to pull that centerboard

Recently Braddock worked on a McDermott cable layer, out through the O3 level, through the bridge. They actually the North Ocean 102 which was contracted by McDermott had a soft patch on the bridge, and then on the ? ying bridge and came into the shipyard in early 2024 for an aggressive, we had to pull both of those out with our large crane. We had 30-day dry docking package. to pull it all the way out, blast and paint it, do some work on “It was ? ve main propulsion units that needed to be the transducers and sensors on there, and then reinstall that swapped, so it involved two main thrusters and two tunnel thing. That was a job in and of itself.

thrusters, as well as one drop-down thruster, as well as a They both had main engine room work. They had diesel 100% blast of the underwater hull freeboard. [With the work overhauls on the Pisces. And on the Oregon, they had MRG package and aggressive timeline] it was a big coordination work. That engine room was packed, and you could tell that effort between paint and the Kongsberg [thruster] reps [to the ship was built around that engine room. So, in order to line-up the work]. It was tough, especially in that aggressive pull the generators out, we had to basically cut the entire up- 30-day window,” said Braddock. per level of the engine room out and rig those things out to

Following that, Braddock was involved in work on a pair of ? t them, which was a job.

NOAA ships, speci? cally the Pisces and Oregon Two NOAA has a great crew of port engineers, and they were here “The Oregon Two came in a couple of days after the RBN for about two months each, so I worked them simultaneously. ship left, and Pisces came in about four hours after Bah- rain left. So, I went from a year and 10-month job straight www.detyens.com to NOAA. Both ships went in the Dry Dock One, where 22 September/October 2024

MTR #7 (18-33).indd 22 10/8/2024 12:45:10 PM

21

21

23

23