Page 22: of Maritime Logistics Professional Magazine (Q3 2014)

Power & Fuel Management

Read this page in Pdf, Flash or Html5 edition of Q3 2014 Maritime Logistics Professional Magazine

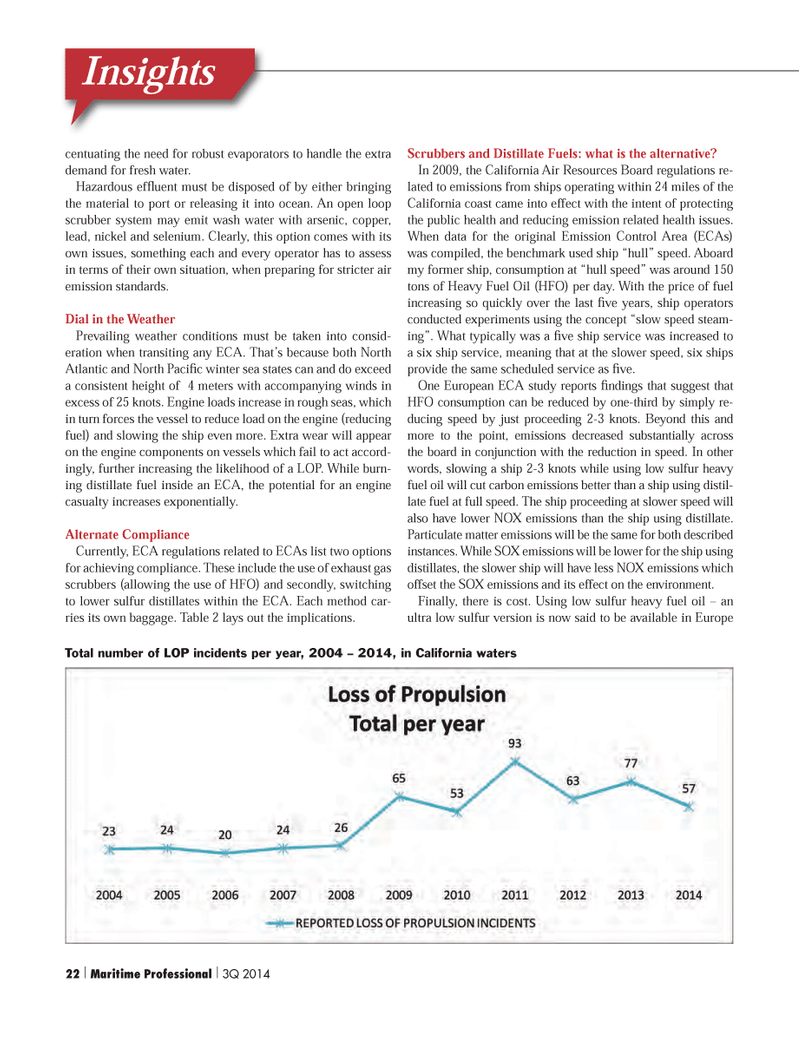

centuating the need for robust evaporators to handle the extra demand for fresh water. Hazardous efß uent must be disposed of by either bringing the material to port or releasing it into ocean. An open loop scrubber system may emit wash water with arsenic, copper, lead, nickel and selenium. Clearly, this option comes with its own issues, something each and every operator has to assess in terms of their own situation, when preparing for stricter air emission standards.Dial in the Weather Prevailing weather conditions must be taken into consid- eration when transiting any ECA. ThatÕs because both North Atlantic and North PaciÞ c winter sea states can and do exceed a consistent height of 4 meters with accompanying winds in excess of 25 knots. Engine loads increase in rough seas, which in turn forces the vessel to reduce load on the engine (reducing fuel) and slowing the ship even more. Extra wear will appear on the engine components on vessels which fail to act accord- ingly, further increasing the likelihood of a LOP. While burn- ing distillate fuel inside an ECA, the potential for an engine casualty increases exponentially. Alternate Compliance Currently, ECA regulations related to ECAs list two options for achieving compliance. These include the use of exhaust gas scrubbers (allowing the use of HFO) and secondly, switching to lower sulfur distillates within the ECA. Each method car- ries its own baggage. Table 2 lays out the implications. Scrubbers and Distillate Fuels: what is the alternative? In 2009, the California Air Resources Board regulations re- lated to emissions from ships operating within 24 miles of the California coast came into effect with the intent of protecting the public health and reducing emission related health issues. When data for the original Emission Control Area (ECAs) was compiled, the benchmark used ship ÒhullÓ speed. Aboard my former ship, consumption at Òhull speedÓ was around 150 tons of Heavy Fuel Oil (HFO) per day. With the price of fuel increasing so quickly over the last Þ ve years, ship operators conducted experiments using the concept Òslow speed steam- ingÓ. What typically was a Þ ve ship service was increased to a six ship service, meaning that at the slower speed, six ships provide the same scheduled service as Þ ve. One European ECA study reports Þ ndings that suggest that HFO consumption can be reduced by one-third by simply re-ducing speed by just proceeding 2-3 knots. Beyond this and more to the point, emissions decreased substantially across the board in conjunction with the reduction in speed. In other words, slowing a ship 2-3 knots while using low sulfur heavy fuel oil will cut carbon emissions better than a ship using distil-late fuel at full speed. The ship proceeding at slower speed will also have lower NOX emissions than the ship using distillate. Particulate matter emissions will be the same for both described instances. While SOX emissions will be lower for the ship using distillates, the slower ship will have less NOX emissions which offset the SOX emissions and its effect on the environment. Finally, there is cost. Using low sulfur heavy fuel oil Ð an ultra low sulfur version is now said to be available in Europe InsightsTotal number of LOP incidents per year, 2004 ? 2014, in California waters 22 | Maritime Professional | 3Q 201418-33 Q3 MP2014.indd 2218-33 Q3 MP2014.indd 228/13/2014 3:33:40 PM8/13/2014 3:33:40 PM

21

21

23

23