Page 13: of Maritime Logistics Professional Magazine (Q4 2014)

Read this page in Pdf, Flash or Html5 edition of Q4 2014 Maritime Logistics Professional Magazine

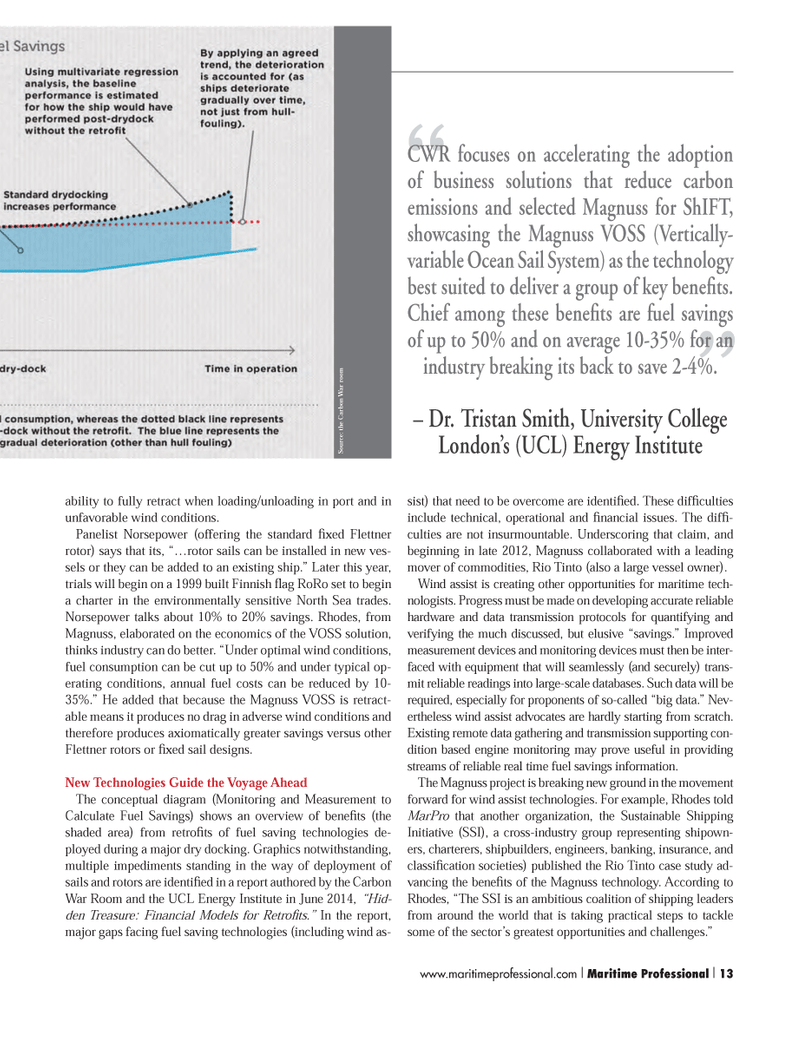

??CWR focuses on accelerating the adoption of business solutions that reduce carbon emissions and selected Magnuss for ShIFT, showcasing the Magnuss VOSS (Vertically- variable Ocean Sail System) as the technology best suited to deliver a group of key beneÞ ts. Chief among these beneÞ ts are fuel savings of up to 50% and on average 10-35% for an industry breaking its back to save 2-4%. Ð Dr. Tristan Smith, University College LondonÕs (UCL) Energy Institute ability to fully retract when loading/unloading in port and in unfavorable wind conditions. Panelist Norsepower (offering the standard Þ xed Flettner rotor) says that its, ÒÉrotor sails can be installed in new ves- sels or they can be added to an existing ship.Ó Later this year, trials will begin on a 1999 built Finnish ß ag RoRo set to begin a charter in the environmentally sensitive North Sea trades. Norsepower talks about 10% to 20% savings. Rhodes, from Magnuss, elaborated on the economics of the VOSS solution, thinks industry can do better. ÒUnder optimal wind conditions, fuel consumption can be cut up to 50% and under typical op-erating conditions, annual fuel costs can be reduced by 10-35%.Ó He added that because the Magnuss VOSS is retract- able means it produces no drag in adverse wind conditions and therefore produces axiomatically greater savings versus other Flettner rotors or Þ xed sail designs. New Technologies Guide the Voyage Ahead The conceptual diagram (Monitoring and Measurement to Calculate Fuel Savings) shows an overview of beneÞ ts (the shaded area) from retroÞ ts of fuel saving technologies de- ployed during a major dry docking. Graphics notwithstanding, multiple impediments standing in the way of deployment of sails and rotors are identiÞ ed in a report authored by the Carbon War Room and the UCL Energy Institute in June 2014, ?Hid-den Treasure: Financial Models for Retro ts.? In the report, major gaps facing fuel saving technologies (including wind as- sist) that need to be overcome are identiÞ ed. These difÞ culties include technical, operational and Þ nancial issues. The difÞ -culties are not insurmountable. Underscoring that claim, and beginning in late 2012, Magnuss collaborated with a leading mover of commodities, Rio Tinto (also a large vessel owner). Wind assist is creating other opportunities for maritime tech- nologists. Progress must be made on developing accurate reliable hardware and data transmission protocols for quantifying and verifying the much discussed, but elusive Òsavings.Ó Improved measurement devices and monitoring devices must then be inter- faced with equipment that will seamlessly (and securely) trans- mit reliable readings into large-scale databases. Such data will be required, especially for proponents of so-called Òbig data.Ó Nev- ertheless wind assist advocates are hardly starting from scratch. Existing remote data gathering and transmission supporting con-dition based engine monitoring may prove useful in providing streams of reliable real time fuel savings information. The Magnuss project is breaking new ground in the movement forward for wind assist technologies. For example, Rhodes told MarPro that another organization, the Sustainable Shipping Initiative (SSI), a cross-industry group representing shipown- ers, charterers, shipbuilders, engineers, banking, insurance, and classiÞ cation societies) published the Rio Tinto case study ad- vancing the beneÞ ts of the Magnuss technology. According to Rhodes, ÒThe SSI is an ambitious coalition of shipping leaders from around the world that is taking practical steps to tackle some of the sectorÕs greatest opportunities and challenges.Ó Source: the Carbon War room www.maritimeprofessional.com I Maritime Professional I 131-17 Q4 MP2014.indd 131-17 Q4 MP2014.indd 1311/17/2014 2:49:26 PM11/17/2014 2:49:26 PM

12

12

14

14