Page 55: of Maritime Logistics Professional Magazine (Mar/Apr 2017)

IT & SOFTWARE

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2017 Maritime Logistics Professional Magazine

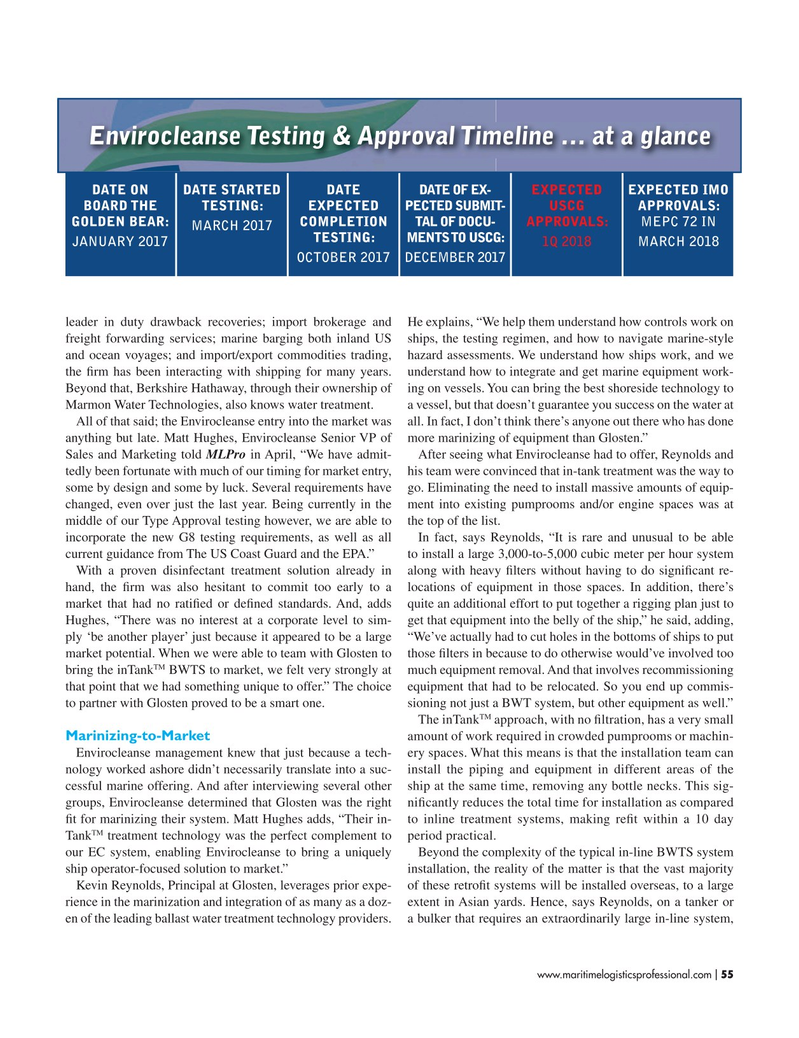

Envirocleanse Testing & Approval Timeline … at a glance

DATE ON DATE STARTED DATE DATE OF EX- EXPECTED EXPECTED IMO

BOARD THE TESTING: EXPECTED PECTED SUBMIT- USCG APPROVALS:

GOLDEN BEAR: COMPLETION TAL OF DOCU- APPROVALS: MEPC 72 IN

MARCH 2017

TESTING: MENTS TO USCG:

JANUARY 2017 1Q 2018 MARCH 2018

OCTOBER 2017 DECEMBER 2017 leader in duty drawback recoveries; import brokerage and He explains, “We help them understand how controls work on freight forwarding services; marine barging both inland US ships, the testing regimen, and how to navigate marine-style and ocean voyages; and import/export commodities trading, hazard assessments. We understand how ships work, and we the ? rm has been interacting with shipping for many years. understand how to integrate and get marine equipment work-

Beyond that, Berkshire Hathaway, through their ownership of ing on vessels. You can bring the best shoreside technology to

Marmon Water Technologies, also knows water treatment. a vessel, but that doesn’t guarantee you success on the water at

All of that said; the Envirocleanse entry into the market was all. In fact, I don’t think there’s anyone out there who has done anything but late. Matt Hughes, Envirocleanse Senior VP of more marinizing of equipment than Glosten.”

Sales and Marketing told MLPro in April, “We have admit- After seeing what Envirocleanse had to offer, Reynolds and tedly been fortunate with much of our timing for market entry, his team were convinced that in-tank treatment was the way to some by design and some by luck. Several requirements have go. Eliminating the need to install massive amounts of equip- changed, even over just the last year. Being currently in the ment into existing pumprooms and/or engine spaces was at middle of our Type Approval testing however, we are able to the top of the list.

incorporate the new G8 testing requirements, as well as all In fact, says Reynolds, “It is rare and unusual to be able current guidance from The US Coast Guard and the EPA.” to install a large 3,000-to-5,000 cubic meter per hour system

With a proven disinfectant treatment solution already in along with heavy ? lters without having to do signi? cant re- hand, the ? rm was also hesitant to commit too early to a locations of equipment in those spaces. In addition, there’s market that had no rati? ed or de? ned standards. And, adds quite an additional effort to put together a rigging plan just to

Hughes, “There was no interest at a corporate level to sim- get that equipment into the belly of the ship,” he said, adding, ply ‘be another player’ just because it appeared to be a large “We’ve actually had to cut holes in the bottoms of ships to put market potential. When we were able to team with Glosten to those ? lters in because to do otherwise would’ve involved too

TM bring the inTank BWTS to market, we felt very strongly at much equipment removal. And that involves recommissioning that point that we had something unique to offer.” The choice equipment that had to be relocated. So you end up commis- to partner with Glosten proved to be a smart one. sioning not just a BWT system, but other equipment as well.”

TM

The inTank approach, with no ? ltration, has a very small

Marinizing-to-Market amount of work required in crowded pumprooms or machin-

Envirocleanse management knew that just because a tech- ery spaces. What this means is that the installation team can nology worked ashore didn’t necessarily translate into a suc- install the piping and equipment in different areas of the cessful marine offering. And after interviewing several other ship at the same time, removing any bottle necks. This sig- groups, Envirocleanse determined that Glosten was the right ni? cantly reduces the total time for installation as compared ? t for marinizing their system. Matt Hughes adds, “Their in- to inline treatment systems, making re? t within a 10 day

TM

Tank treatment technology was the perfect complement to period practical.

our EC system, enabling Envirocleanse to bring a uniquely Beyond the complexity of the typical in-line BWTS system ship operator-focused solution to market.” installation, the reality of the matter is that the vast majority

Kevin Reynolds, Principal at Glosten, leverages prior expe- of these retro? t systems will be installed overseas, to a large rience in the marinization and integration of as many as a doz- extent in Asian yards. Hence, says Reynolds, on a tanker or en of the leading ballast water treatment technology providers. a bulker that requires an extraordinarily large in-line system, www.maritimelogisticsprofessional.com 55

I

54

54

56

56