Page 41: of Maritime Reporter Magazine (March 1969)

Read this page in Pdf, Flash or Html5 edition of March 1969 Maritime Reporter Magazine

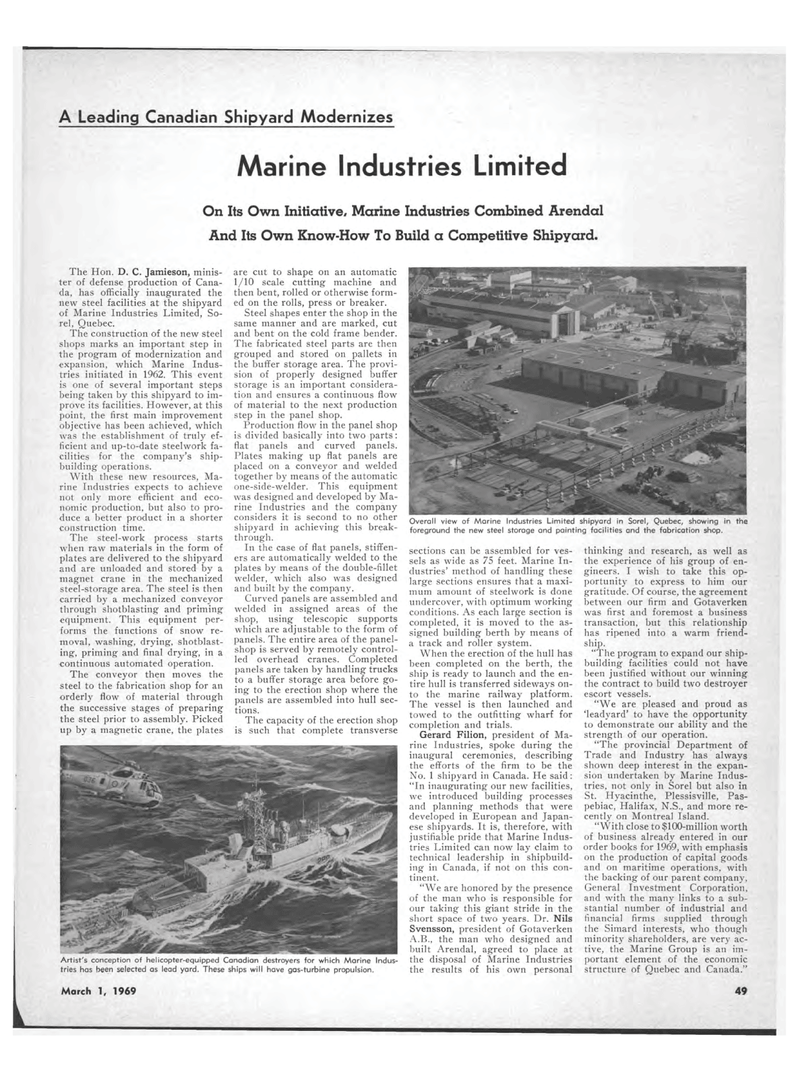

A Leading Canadian Shipyard Modernizes Marine Industries Limited On Its Own Initiative, Marine Industries Combined Arendal And Its Own Know-How To Build a Competitive Shipyard. Overall view of Marine Industries Limited shipyard in Sorel, Quebec, showing in the foreground the new steel storage and painting facilities and the fabrication shop. The Hon. D. C. Jamieson, minis-ter of defense production of Cana-da, has officially inaugurated the new steel facilities at the shipyard of Marine Industries Limited, So-rel, Quebec. The construction of the new steel shops marks an important step in the program of modernization and expansion, which Marine Indus-tries initiated in 1962. This event is one of several important steps being taken by this shipyard to im-prove its facilities. However, at this point, the first main improvement objective has been achieved, which was the establishment of truly ef-ficient and up-to-date steelwork fa-cilities for the company's ship-building operations. With these new resources, Ma-rine Industries expects to achieve not only more efficient and eco-nomic production, but also to pro-duce a better product in a shorter construction time. The steel-work process starts when raw materials in the form of plates are delivered to the shipyard and are unloaded and stored by a magnet crane in the mechanized steel-storage area. The steel is then carried by a mechanized conveyor through shotblasting and priming equipment. This equipment per-forms the functions of snow re-moval, washing, drying, shotblast-ing, priming and final drying, in a continuous automated operation. The conveyor then moves the steel to the fabrication shop for an orderly flow of material through the successive stages of preparing the steel prior to assembly. Picked up by a magnetic crane, the plates are cut to shape on an automatic 1/10 scale cutting machine and then bent, rolled or otherwise form-ed on the rolls, press or breaker. Steel shapes enter the shop in the same manner and are marked, cut and bent on the cold frame bender. The fabricated steel parts are then grouped and stored on pallets in the buffer storage area. The provi-sion of properly designed buffer storage is an important considera-tion and ensures a continuous flow of material to the next production step in the panel shop. Production flow in the panel shop is divided basically into two parts: flat panels and curved panels. Plates making up flat panels are placed on a conveyor and welded together by means of the automatic one-side-welder. This equipment was designed and developed by Ma-rine Industries and the company considers it is second to no other shipyard in achieving this break-through. In the case of flat panels, stiffen-ers are automatically welded to the plates by means of the double-fillet welder, which also was designed and built by the company. Curved panels are assembled and welded in assigned areas of the shop, using telescopic supports which are adjustable to the form of panels. The entire area of the panel-shop is served by remotely control-led overhead cranes. Completed panels are taken by handling trucks to a buffer storage area before go-ing to the erection shop where the panels are assembled into hull sec-tions. The capacity of the erection shop is such that complete transverse sections can be assembled for ves-sels as wide as 75 feet. Marine In-dustries' method of handling these large sections ensures that a maxi-mum amount of steelwork is done undercover, with optimum working conditions. As each large section is completed, it is moved to the as-signed building berth by means of a track and roller system. When the erection of the hull has been completed on the berth, the ship is ready to launch and the en-tire hull is transferred sideways on-to the marine railway platform. The vessel is then launched and towed to the outfitting wharf for completion and trials. Gerard Filion, president of Ma-rine Industries, spoke during the inaugural ceremonies, describing the efforts of the firm to be the No. 1 shipyard in Canada. He said: "In inaugurating our new facilities, we introduced building processes and planning methods that were developed in European and Japan-ese shipyards. It is, therefore, with justifiable pride that Marine Indus-tries Limited can now lay claim to technical leadership in shipbuild-ing in Canada, if not on this con-tinent. "We are honored by the presence of the man who is responsible for our taking this giant stride in the short space of two years. Dr. Nils Svensson, president of Gotaverken A.B., the man who designed and built Arendal, agreed to place at the disposal of Marine Industries the results of his own personal thinking and research, as well as the experience of his group of en-gineers. I wish to take this op-portunity to express to him our gratitude. Of course, the agreement between our firm and Gotaverken was first and foremost a business transaction, but this relationship has ripened into a warm friend-ship. "The program to expand our ship-building facilities could not have been justified without our winning the contract to build two destroyer escort vessels. "We are pleased and proud as 'leadyard' to have the opportunity to demonstrate our ability and the strength of our operation. "The provincial Department of Trade and Industry has always shown deep interest in the expan-sion undertaken by Marine Indus-tries, not only in Sorel but also in St. Hyacinthe, Plessisville, Pas-pebiac, Halifax, N.S., and more re-cently on Montreal Island. "With close to $100-million worth of business already entered in our order books for 1969, with emphasis on the production of capital goods and on maritime operations, with the backing of our parent company, General Investment Corporation, and with the many links to a sub-stantial number of industrial and financial firms supplied through the Simard interests, who though minority shareholders, are very ac-tive, the Marine Group is an im-portant element of the economic structure of Quebec and Canada." Artist's conception of helicopter-equipped Canadian destroyers for which Marine Indus-tries has been selected as lead yard. These ships will have gas-turbine propulsion. March 1, 1969 43

40

40

42

42