Page 41: of Maritime Reporter Magazine (April 1969)

Read this page in Pdf, Flash or Html5 edition of April 1969 Maritime Reporter Magazine

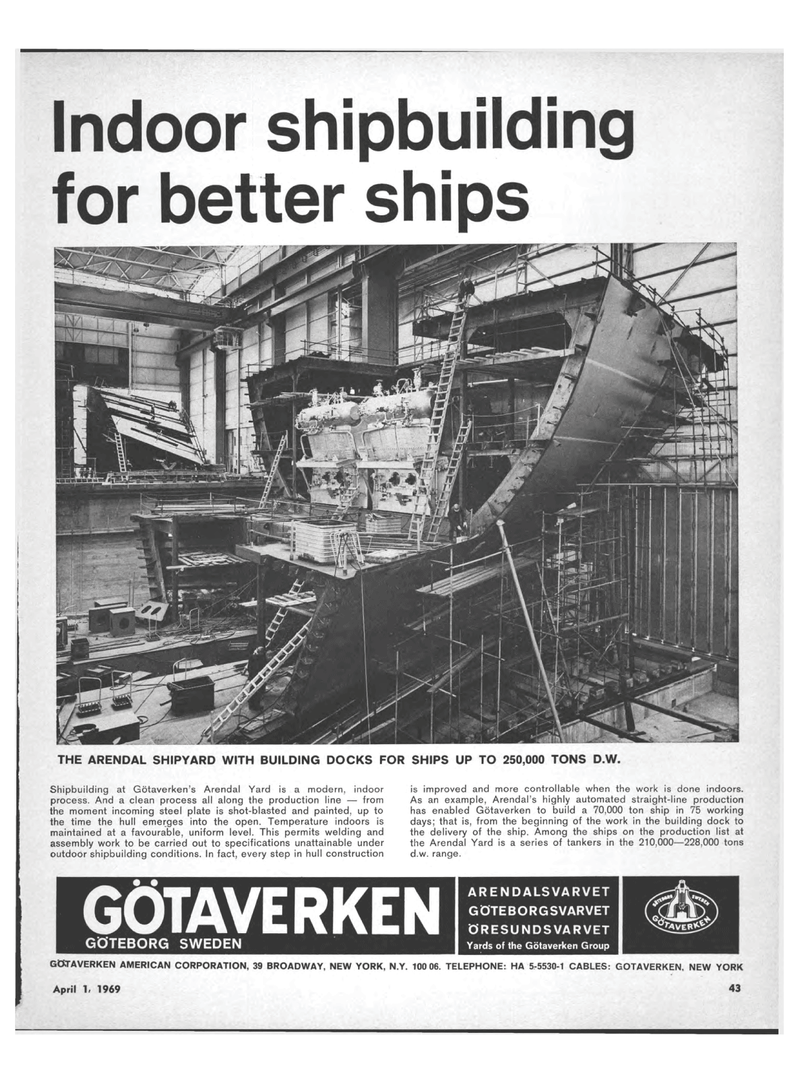

Indoor shipbuilding for better ships THE ARENDAL SHIPYARD WITH BUILDING DOCKS FOR SHIPS UP TO 250,000 TONS D.W. Shipbuilding at Gotaverken's Arendal Yard is a modern, indoor process. And a clean process all along the production line ? from the moment incoming steel plate is shot-blasted and painted, up to the time the hull emerges into the open. Temperature indoors is maintained at a favourable, uniform level. This permits welding and assembly work to be carried out to specifications unattainable under outdoor shipbuilding conditions. In fact, every step in hull construction is improved and more controllable when the work is done indoors. As an example, Arendal's highly automated straight-line production has enabled Gotaverken to build a 70,000 ton ship in 75 working days; that is, from the beginning of the work in the building dock to the delivery of the ship. Among the ships on the production list at the Arendal Yard is a series of tankers in the 210,000?228,000 tons d.w. range. GOTAVERKEN GOTEBORG SWEDEN ARENDALSVARVET GOTEBORGSVARVET ORESUNDSVARVET Yards of the Gotaverken Group GOTAVERKEN AMERICAN CORPORATION, 39 BROADWAY, NEW YORK, N.Y. 100 06. TELEPHONE: HA 5-5530-1 CABLES: GOTAVERKEN, NEW YORK April T, 1969 43

40

40

42

42