Page 22: of Maritime Reporter Magazine (July 1969)

Read this page in Pdf, Flash or Html5 edition of July 1969 Maritime Reporter Magazine

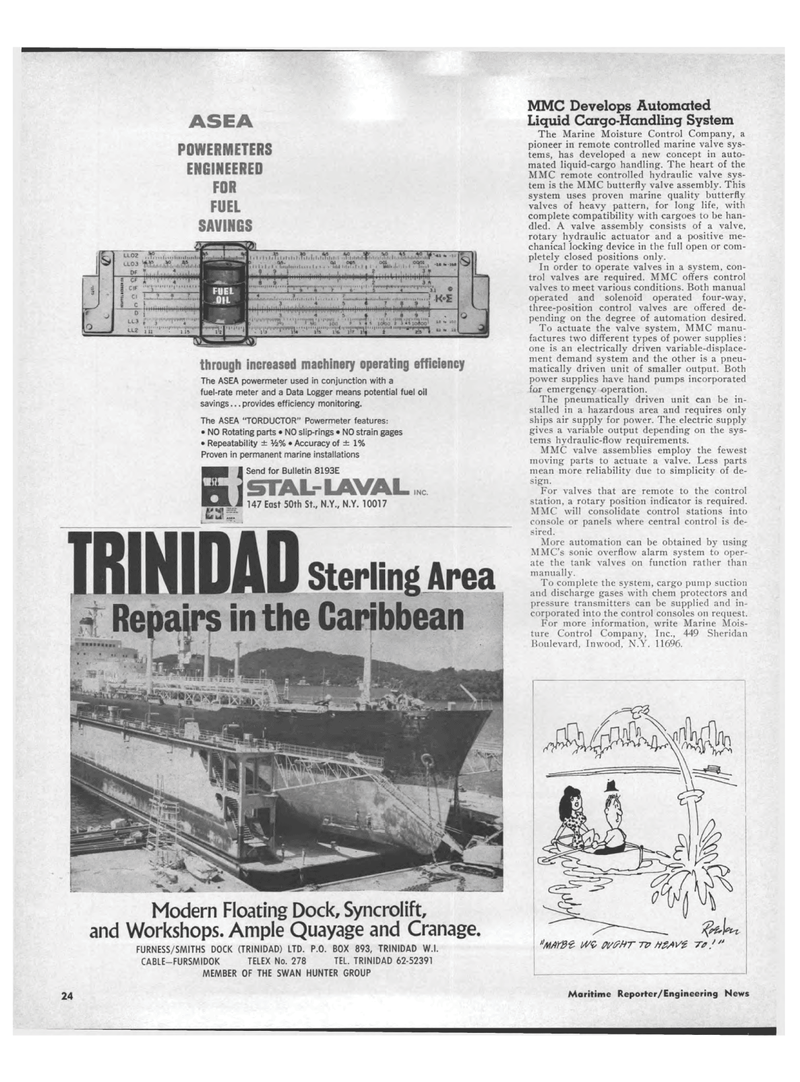

ASEA POWERMETERS ENGINEERED FOR FUEL SAVINGS through increased machinery operating efficiency The ASEA powermeter used in conjunction with a fuel-rate meter and a Data Logger means potential fuel oil savings... provides efficiency monitoring. The ASEA "TORDUCTOR" Powermeter features: ? NO Rotating parts ? NO slip-rings ? NO strain gages ? Repeatability ± Vz% ? Accuracy of ± 1% Proven in permanent marine installations Send for Bulletin 8193E STAL-LAVAL , 147 East 50th St., N.Y., N.Y. 10017 Si i rzfxJZA Modern Floating Dock, Syncrolift, and Workshops. Ample Quayage and Cranage. FURNESS/SMITHS DOCK (TRINIDAD) LTD. P.O. BOX 893, TRINIDAD W.I. CABLE?FURSMIDOK TELEX No. 278 TEL. TRINIDAD 62-52391 MEMBER OF THE SWAN HUNTER GROUP MMC Develops Automated Liquid Cargo-Handling System The Marine Moisture Control Company, a pioneer in remote controlled marine valve sys-tems, has developed a new concept in auto-mated liquid-cargo handling. The heart of the MMC remote controlled hydraulic valve sys-tem is the MMC butterfly valve assembly. This system uses proven marine quality butterfly valves of heavy pattern, for long life, with complete compatibility with cargoes to be han-dled. A valve assembly consists of a valve, rotary hydraulic actuator and a positive me-chanical locking device in the full open or com-pletely closed positions only. In order to operate valves in a system, con-trol valves are required. MMC offers control valves to meet various conditions. Both manual operated and solenoid operated four-way, three-position control valves are offered de-pending on the degree of automation desired. To actuate the valve system, MMC manu-factures two different types of power supplies: one is an electrically driven variable-displace-ment demand system and the other is a pneu-matically driven unit of smaller output. Both power supplies have hand pumps incorporated for emergency operation. The pneumatically driven unit can be in-stalled in a hazardous area and requires only ships air supply for power. The electric supply gives a variable output depending on the sys-tems hydraulic-flow requirements. MMC valve assemblies employ the fewest moving parts to actuate a valve. Less parts mean more reliability due to simplicity of de-sign. For valves that are remote to the control station, a rotary position indicator is required. MMC will consolidate control stations into console or panels where central control is de-sired. More automation can be obtained by using MMC's sonic overflow alarm system to oper-ate the tank valves on function rather than manually. To complete the system, cargo pump suction and discharge gases with chem protectors and pressure transmitters can be supplied and in-corporated into the control consoles on request. For more information, write Marine Mois-ture Control Company, Inc., 449 Sheridan Boulevard, Inwood, N.Y. 11696. 10 Maritime Reporter/Engineering News

21

21

23

23