Page 36: of Maritime Reporter Magazine (July 1970)

Read this page in Pdf, Flash or Html5 edition of July 1970 Maritime Reporter Magazine

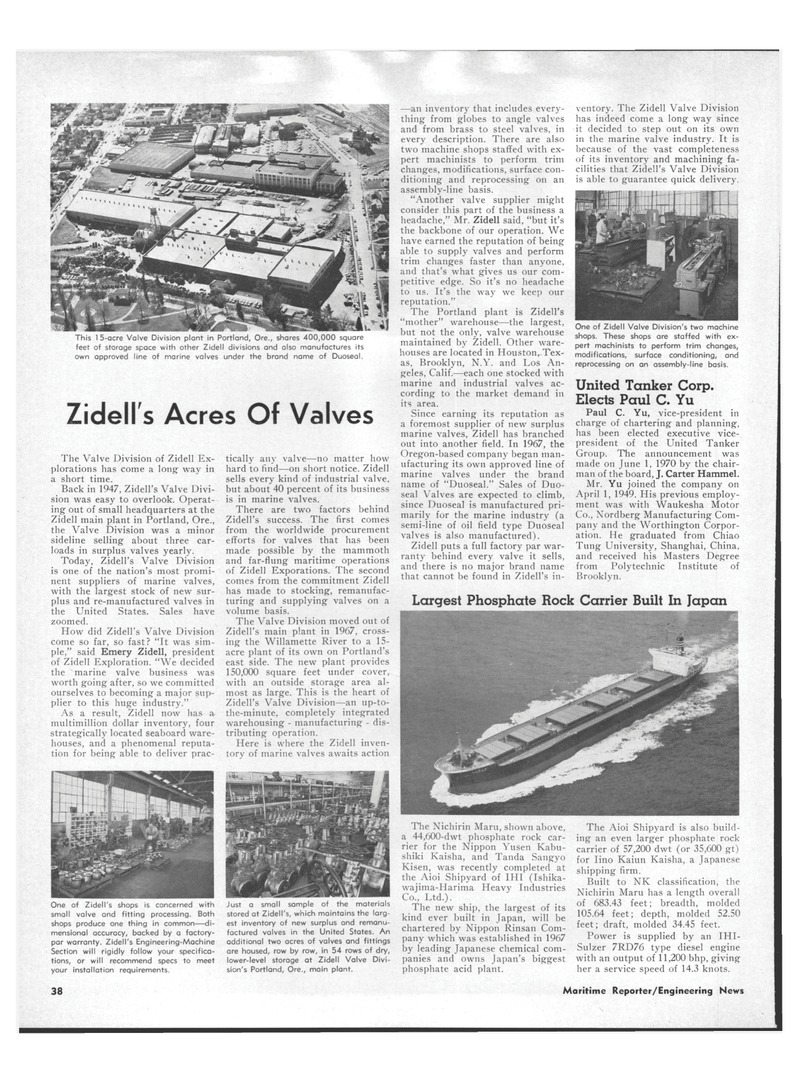

This 1 5-acre Valve Division plant in Portland, Ore., shares 400,000 square feet of storage space with other Zidell divisions and also manufactures its own approved line of marine valves under the brand name of Duoseal.

Zidell's Acres Of Valves

The Valve Division of Zidell Ex- plorations has come a long way in a short time.

Back in 1947. Zidell's Valve Divi- sion was easy to overlook. Operat- ing out of small headquarters at the

Zidell main plant in Portland, Ore., the Valve Division was a minor sideline selling about three car- loads in surplus valves yearly.

Today, Zidell's Valve Division is one of the nation's most promi- nent suppliers of marine valves, with the largest stock of new sur- plus and re-manufactured valves in the United States. Sales have zoomed.

How did Zidell's Valve Division come so far, so fast? "It was sim- ple," said Emery Zidell, president of Zidell Exploration. "We decided the marine valve business was worth going after, so we committed ourselves to becoming a major sup- plier to this huge industry."

As a result, Zidell now has a multimillion dollar inventory, four strategically located seaboard ware- houses, and a phenomenal reputa- tion for being able to deliver prac-

One of Zidell's shops is concerned with small valve and fitting processing. Both shops produce one thing in common—di- mensional accuracy, backed by a factory- par warranty. Zidell's Engineering-Machine

Section will rigidly follow your specifica- tions, or will recommend specs to meet your installation requirements. tically any valve—no matter how hard to find—on short notice. Zidell sells every kind of industrial valve, but about 40 percent of its business is in marine valves.

There are two factors behind

Zidell's success. The first comes from the worldwide procurement efforts for valves that has been made possible by the mammoth and far-flung maritime operations of Zidell Exporations. The second comes from the commitment Zidell has made to stocking, remanufac- turing and supplying valves on a volume basis.

The Valve Division moved out of

Zidell's main plant in 1967, cross- ing the Willamette River to a 15- acre plant of its own on Portland's east side. The new plant provides 150,000 square feet under cover, with an outside storage area al- most as large. This is the heart of

Zidell's Valve Division—an up-to- the-minute, completely integrated warehousing - manufacturing - dis- tributing operation.

Here is where the Zidell inven- tory of marine valves awaits action

Just a small sample of the materials stored at Zidell's, which maintains the larg- est inventory of new surplus and remanu- factured valves in the United States. An additional two acres of valves and fittings are housed, row by row, in 54 rows of dry, lower-level storage at Zidell Valve Divi- sion's Portland, Ore., main plant. —an inventory that includes every- thing from globes to angle valves and from brass to steel valves, in every description. There are also two machine shops staffed with ex- pert machinists to perform trim changes, modifications, surface con- ditioning and reprocessing on an assembly-line basis. "Another valve supplier might consider this part of the business a headache," Mr. Zidell said, "but it's the backbone of our operation. We have earned the reputation of being able to supply valves and perform trim changes faster than anyone, and that's what gives us our com- petitive edge. So it's no headache to us. It's the way we keep our reputation."

The Portland plant is Zidell's "mother" warehouse—the largest, but not the only, valve warehouse maintained by Zidell. Other ware- houses are located in Houston, Tex- as, Brooklyn, N.Y. and Los An- geles, Calif.—each one stocked with marine and industrial valves ac- cording to the market demand in its area.

Since earning its reputation as a foremost supplier of new surplus marine valves, Zidell has branched out into another field. In 1967, the

Oregon-based company began man- ufacturing its own approved line of marine valves under the brand name of "Duoseal." Sales of Duo- seal Valves are expected to climb, since Duoseal is manufactured pri- marily for the marine industry (a semi-line of oil field type Duoseal valves is also manufactured).

Zidell puts a full factory par war- ranty behind every valve it sells, and there is no major brand name that cannot be found in Zidell's in-

The Nichirin Maru, shown above, a 44,600-dwt phosphate rock car- rier for the Nippon Yusen Kabu- shiki Kaisha, and Tanda Sangyo

Kisen, was recently completed at the Aioi Shipyard of IHI (Ishika- wajima-Harima Heavy Industries

Co., Ltd.).

The new ship, the largest of its kind ever built in Japan, will be chartered by Nippon Rinsan Com- pany which was established in 1967 by leading Japanese chemical com- panies and owns Japan's biggest phosphate acid plant. ventory. The Zidell Valve Division has indeed come a long way since it decided to step out on its own in the marine valve industry. It is because of the vast completeness of its inventory and machining fa- cilities that Zidell's Valve Division is able to guarantee quick delivery.

One of Zidell Valve Division's two machine shops. These shops are staffed with ex- pert machinists to perform trim changes, modifications, surface conditioning, and reprocessing on an assembly-line basis.

United Tanker Corp.

Elects Paul C. Yu

Paul C. Yu, vice-president in charge of chartering and planning, has been elected executive vice- president of the United Tanker

Group. The announcement was made on June 1, 1970 by the chair- man of the board, J. Carter Hammel.

Mr. Yu joined the company on

April 1, 1949. His previous employ- ment was with Waukesha Motor

Co., Nordberg Manufacturing Com- pany and the Worthington Corpor- ation. He graduated from Chiao

Tung University, Shanghai, China, and received his Masters Degree from Polytechnic Institute of

Brooklyn.

The Aioi Shipyard is also build- ing an even larger phosphate rock carrier of 57,200 dwt (or 35,600 gt) for lino Kaiun Kaisha, a Japanese shipping firm.

Built to NK classification, the

Nichirin Maru has a length overall of 683.43 feet; breadth, molded 105.64 feet; depth, molded 52.50 feet; draft, molded 34.45 feet.

Power is supplied by an IHI-

Sulzer 7RD76 type diesel engine with an output of 11,200 bhp, giving her a service speed of 14.3 knots.

Largest Phosphate Rock Carrier Built In Japan 38 Maritime Reporter/Engineering News

35

35

37

37