Page 15: of Maritime Reporter Magazine (October 1970)

Read this page in Pdf, Flash or Html5 edition of October 1970 Maritime Reporter Magazine

Armco... the totally involved steel maker

Marine steels. It takes more than furnaces and a rolling mill to pro- duce them.

It takes total involvement... an open dialogue with naval architects and designers, with ship owners and operators, with engineers in the yards and men who weld.

You have to be familiar with a unique breed of specs. ABS, HY- 80, MIL-S-16113C Grade HT . . . to name some. We know them well.

All of them. We specialize in ma- rine steels.

Including new high-strength steels for saving weight, adding strength, improving stability, in- creasing performance in today's modern vessels. Steels like the 100,000psi minimumyield strength

Armco SSS®100 series (ASTM A 514 and A 517). And Armco High-

Strength B (ASTM A 441), with minimum yield strengths up to 50,000 psi, 70,000 psi minimum tensile strength.

Plus a complete family of heat- treated carbon steels providing ex- ceptional notch toughness. New

Armco VNT™ Steel. Armco LTM.

Armco QTC® Steel. And Armco Lo-

Temp™ and Super-Lo-Temp™

Steels (ASTM A 537).

Total involvement means more than just products, too.

It means we welcome the idea of working with you in search of the best steels for your needs. It means a full array of technical data de- signed to assist you in using those steels. It means the metallurgical knowledge of our skilled team is yours whenever it's needed. It means prompt service from people who care. Armco people. Let's get involved . . . Armco Steel Corpora- tion, Department H-30, P. O. Box 723, Houston, Texas 77001.

ARMCO STE ARMCO EL V

Write today for a free copy of the new

Relative Cost and Property Card on

Armco Marine Steels

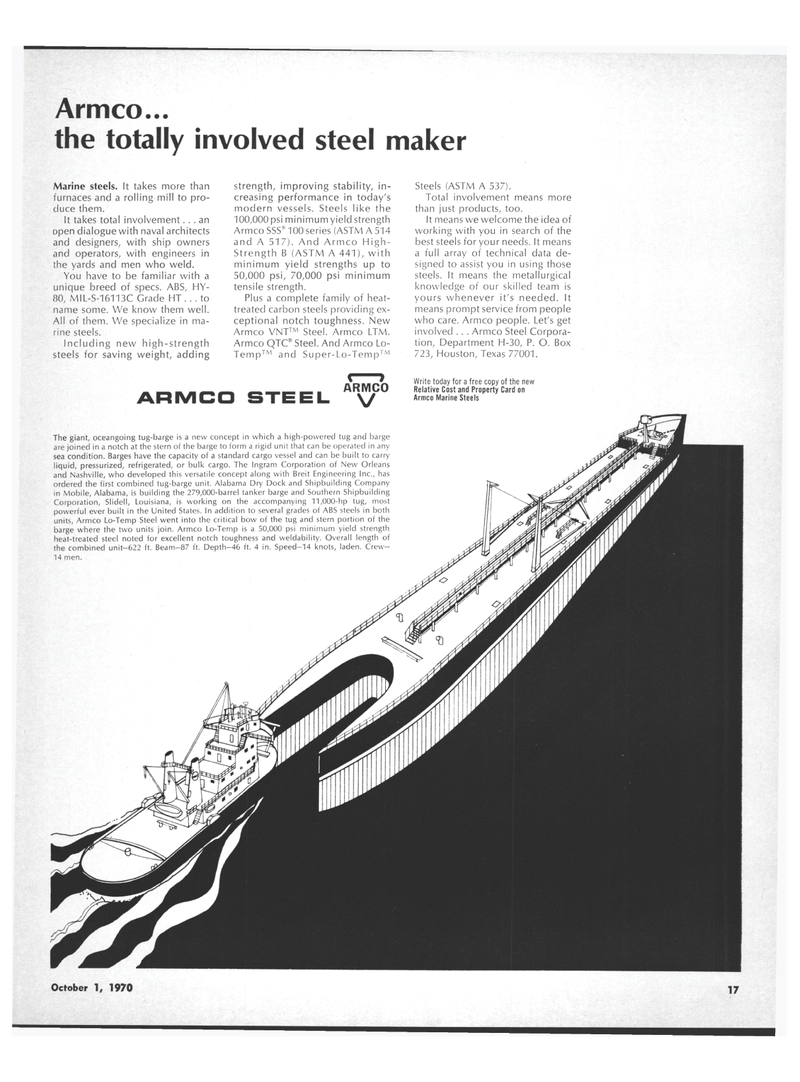

The giant, oceangoing tug-barge is a new concept in which a high-powered tug and barge are joined in a notch at the stern of the barge to form a rigid unit that can be operated in any sea condition. Barges have the capacity of a standard cargo vessel and can be built to carry liquid, pressurized, refrigerated, or bulk cargo. The Ingram Corporation of New Orleans and Nashville, who developed this versatile concept along with Breit Engineering Inc., has ordered the first combined tug-barge unit. Alabama Dry Dock and Shipbuilding Company in Mobile, Alabama, is building the 279,000-barrel tanker barge and Southern Shipbuildin

Corporation, Slidell, Louisiana, is working on the accompanying 11,000-hp tug, most powerful ever built in the United Stales. In addition to several grades of ABS steels in both units, Armco Lo-Temp Steel went into the critical bow of the tug and stern portion of the barge where the two units join. Armco Lo-Temp is a 50,000 psi minimum yield strength heat-treated steel noted for excellent notch toughness and weldability. Overall length of the combined unit-622 ft. Beam-87 ft. Depth-46 ft. 4 in. Speed-14 knots, laden. Crew- 14 men.

October 1, 1970

14

14

16

16