Page 31: of Maritime Reporter Magazine (March 15, 1971)

Read this page in Pdf, Flash or Html5 edition of March 15, 1971 Maritime Reporter Magazine

Willamette-Western

Appoints J.G. Kaady

Mgr. Of Purchasing

Jack G. Kaady has been appoint- ed manager of purchasing for Wil- lamette-Western Corporation, ac- cording to A.A. Riedel, president of the Portland-headquartered di- versified service, marine and heavy construction company.

Since he joined the firm in Sep- tember 1969, Mr. Kaady has served as administrative assistant to both the president and the vice presi- dent in charge of Willamette Hi-

Grade Concrete Co., a Willamette-

Western division.

Six years before he joined Willa- mette-Western, Mr. Kaady was as- sistant to the president of Ross

Island Sand & Gravel Co. He had earlier been accountant for that firm one and a half years.

Mr. Kaady was in the U.S. Navy for four years. He attended the

Supply Corps School in Athens,

Ga., and became a supply officer.

He saw both sea duty and service at the Naval Torpedo Station at

Keyport, Wash. Mr. Kaady is a native of Portland, Ore. He is a 1958 graduate of the University of Oregon, with a major in ac- counting.

Willamette-Western Corporation is a diversified organization orient- ed to the construction industry.

Among various subsidiaries and di- visions are Western-Pacific Dredg- ing Company, Western - Pacific

Piledriving Co., Willamette Hi-

Grade Concrete Co., and Willa- mette Tug & Barge Co. The firm has other offices in Seattle, Ta- coma, and Pasco, Wash., as well as San Francisco and Los Angeles,

Calif. 1970 Chartering Annual

Ready For Distribution

The Chartering Annual for 1970, published by Maritime Research

Inc., 11 Broadway, New York,

N.Y., is available for distribution, the company announced.

The publication, which contains charts and a listing of various ships fixed throughout the year, is arranged by commodity, trade route, dates and rates. The book is obtainable through subscription only, at a cost of $25 per copy.

IHI Asks Permission

To Build New Shipyard

IHI (Ishikawajima-Harima

Heavy Industries Co., Ltd.), the leading Japanese shipbuilder, has applied to the Japanese Ministry of Transport for permission for a new shipyard construction project.

The new shipyard, tentatively named IHI Chita Shipyard, will be constructed on approximately 8,- 250,000 square feet of reclaimed land in the Chita Peninsula, Aichi

Prefecture, in southern Japan.

Upon receiving permission from the Ministry of Transport, con- struction work will begin, with completion scheduled for Decem- ber 1973. Construction of the first ship will begin in September 1972, while construction of a building dock is in progress. The cost of the new shipyard will be approxi- mately $61 million.

The shipyard will have a build- ing dock approximately 2,650 feet long, 300 feet wide and 45 feet deep, with two 350^ton goliath cranes and two 30-ton jib cranes.

The yard will build five ships of the 250,000-dwt class yearly.

For efficient and continuous shipbuilding, the dock will be di- vided in three portions, and a ship will be built at three stages—the stern at the first stage, the mid- section at the second stage, and the stem at the third stage. All ship construction work from keel-laying to completion, including the out- fitting work, will be conducted in the dock, and on leaving the dock, the ship will be able to undergo a trial run immediately.

Construction of the new ship- yard was projected to cope with the recent increasing demand for large ships. When the new yard is completed, IHI will discontinue shipbuilding in its Nagoya Ship- yard (maximum ship, 60,000 dwt) and ship its employees to the new yard. Labor-saving schemes will limit the number of employees at the new yard to 1,350. The Na- goya Shipyard will switch its pro- duction to machinery and steel structures. 1HE ASEA mm

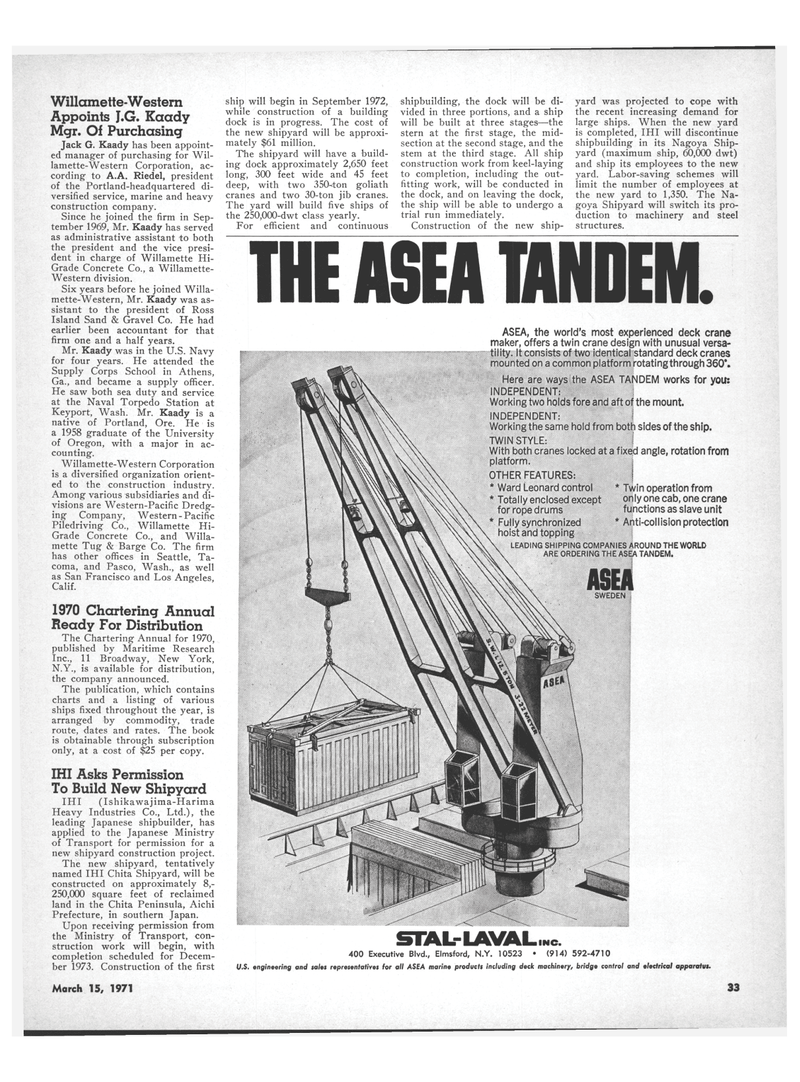

ASEA, the world's most experienced deck crane maker, offers a twin crane design with unusual versa- tility. It consists of two identical standard deck cranes mounted on a common platform rotating through 360*.

Here are ways the ASEA TANDEM works for you:

INDEPENDENT:

Working two holds fore and aft of the mount.

INDEPENDENT: , j

Working the same hold from both sides of the ship.

TWIN STYLE:

With both cranes locked at a fixed angle, rotation from platform.

OTHER FEATURES: * Ward Leonard control * Totally enclosed except for rope drums * Fully synchronized hoist and topping

LEADING SHIPPING COMPANIES AROUND THE WORLD

ARE ORDERING THE ASEA TANDEM.

SWEDEN

Twin operation from only one cab, one crane functions as slave unit

Anti-collision protection

STAL-LAVAL INC. 400 Executive Blvd., Elmsford, N.Y. 10523 • (914) 592-4710

U.S. engineering and sales representatives for all ASEA marine products including deck machinery, bridge control and electrical apparatus.

March 15, 1971 33

30

30

32

32