Page 7: of Maritime Reporter Magazine (November 1971)

Read this page in Pdf, Flash or Html5 edition of November 1971 Maritime Reporter Magazine

Alcoa Seaprobe- (Continued from page 7) minuim structure of its type to com- ply with Coast Guard regulations for structural fire protection."

Aluminum sheet, plate, extru- sions, tuibular products and weld- ing electrode from Alcoa plants at

Davenport, Iowa; Lafayette, Ind., and Massena, N.Y. were used in building the Alcoa Seaprobe. As an example of the product require- ments for a jc>b of such scope, more than one thousand miles of alumi- num electrode and filler rod were used to join the hull, framing and superstructure sections.

The Design

The 243-foot (overall length) Al- coa Seaprobe has a 50-foot beam, a hull draft of 8 feet and a total draft over the vertical-axis propel- lers of 14 feet, and a displacement of 1,700 tons. The ship has a 45- day cruising range of approximate- ly 6,600 miles. It has a speed of 10 knots.

The hull form incorporates a chine which allowed for extensive use of flat plates for the shell.

Amidships is the drawworks which are similar to those on off-shore oil-drilling platforms. A helicopter platform is provided on the stern of the vessel.

Propulsion is provided by two

Voith-Schneider, cycloidal, omni- directional propulsion units. The main source of electrical power for driving these vertical-axis propel- lers are two 800-kw General Motors diesel generator sets. Auxiliary power is supplied by two 250jkw

General Motors diesel generator sets. The propulsion motors and controls were supplied by Electric

Machinery Manufacturing Com- pany.

The Alcoa Seaprobe can be con- trolled either from a console on the bridge or a console in the search/ recovery control center. These units were supplied 'by Decca.

The derrick has a height of 132 feet above the waterline. It is con- structed of 6061-T6 aluminum tulb- ing and 5456-H321 aluminum plate.

It was designed for a hook load of 250 tons with a safety factor of two.

The drawworks is an EM SCO 800 with a 600-'hp motor-generator power supply for d-c control. The 4i/2-inch diameter OD, upset-in-

Suppliers

Manufacturers, other than those men- tioned previously, supplied the follow- ing equipment for the Alcoa Seaprobe:

Windlasses Clark Chapman & Co.

Airhorns Kohlenberg

Distilling Plant AMF Cuno Div.

Echo Sounder Edo Western Corp.

Loran ITT Mackay Marine

Anchors Baldt

Emergency Generator Kohler

Cathodic Protection

Engelhard Industries

Radar Decca

Air Conditioning Carrier Corp.

Switchboards Federal Pacific

Monitoring System Decca

Radio Equipment ITT Mackay and RF Communications ternal flush pipe in 60-foot sections is handled by a semi-automatic pipe-handling system.

There are two A.B. Chance 5-ton

Oceanographic cranes with inter- changeable winch drums for han- dling equipment on the deck or over the side.

Operations

The Alcoa Seaprobe is a dynami- cally positioned ocean working platform. The ship can be pre- cisely navigated for fine grain area searches and can hold a precision position in the open sea against winds and currents with the aid of the following systems: 1. Ocean-bottom-mounted acou- stic reference systems, 2. Land-based, precision short- range and medium-range radio lo- cation systems, 3. Radar positioning relative to land-based or moored reference points, and 4. Worldwide positioning sys- tems employing satellites and/or

VLF Omega.

Using a semi-rigid pipe system, the Alcoa Seaprobe deploys a search, identification and sensor package in close proximity to the ocean floor. The system is designed to permit accurate control of the sensor package relative to the ship's working platform and with regard to the sea floor or objects on the floor.

A thruster system at the work- ing end of the pipe provides preci- sion control and positioning of sen- sor packages, recovery mechan- isms, viewing or recording systems, and real-time television examina- tion of deep-ocean objects.

Using sonar and television for target location and identification,

Alcoa SeaprObe is designed to be capable of selectively lifting multi- ton weights from the sea floor. This lift capacity is made possible by the tensile strength of the 4i/2-inch diameter drill pipe.

The business end of the Alcoa

SeaprObe system is located at the end of a pipe string made of 60- foot segments of drill pipe thread- ed together to reach the ocean depths required. Depending upon the task at hand, sensor systems are deployed for fine-grain bot- tom search and examination, target identification and marking, or oceanographic sampling and measurement. Recovery devices ranging ifrom multi-purpose grap- pling claws to coring tools are available for lifting bottom objects or cores to the surface. A cable affixed to the exterior of the pipe provides the necessary electrical power, telemetry control signals, and data transmission circuits be- tween the shipboard control con- soles and the sensor systems prob- ing the deep ocean.

Search—The basic search "pod" deploys side-scan sonar to sweep a 2,400-foot path along the sea floor.

The pod is configured with forward looking sonar, television, still cam- era, target-illumination systems, and a dropaible acoustic beacon to use in marking specific target loca- tions.

Additional sensors, detectors and other special devices may be added to the pod to meet the require- ments of specific missions.

Recovery—Heavy object recov- ery devices utilize rugged electro- mechanical and hydraulic systems for closure and holding control.

Precise positioning of the recovery device with respect to the target is effected by sonar and transpond- er sensing devices in concert with remotely monitored television and target-illumination systems.

Sampling—In concert with tele- vision examination, bottom sam- ples may be selectively recovered for the purpose of magnetic, chem- ical, biological, geological and pa- leontological studies. Shipboard precision navigation systems and a thruster system to control the end of the drill string permit finite positioning of devices and sensors with regard to the ocean floor.

Coring—The Alcoa Seaprobe can be outfitted to core in water depths to 18,000 feet. A bottom-oriented acoustic reference system is used to maintain position in the open ocean and permits wire-line recov- ery of cores for paleontologic and magnetic stratigraphy. Cores also can be recovered for studies con- cerned with the mechanism of sedi- ment supply, transport, deposition, and to confirm seismic survey data for scientific or other exploratory purposes.

Its capabilities for research and exploratory oceanographic func- tions exceed those of any ship ex- isting or proposed.

Ocean Search, Inc. is a venture of the Aluminum Company of

America and Ocean Science and

Engineering, Inc. It was formed to coordinate a variety of world- wide exploratory projects related to the ocean environment and its enormous potential for mankind's welfare. Alcoa has joined OSE in this venture which spearheads Al- coa's expanded involvement in oceanography.

Ocean Search, Inc. invites both individual scientists and organiza- tions to conceive and propose pro- jects now which will challenge the capabilities of this new deep-ocean tool, the Alcoa Seaprobe.

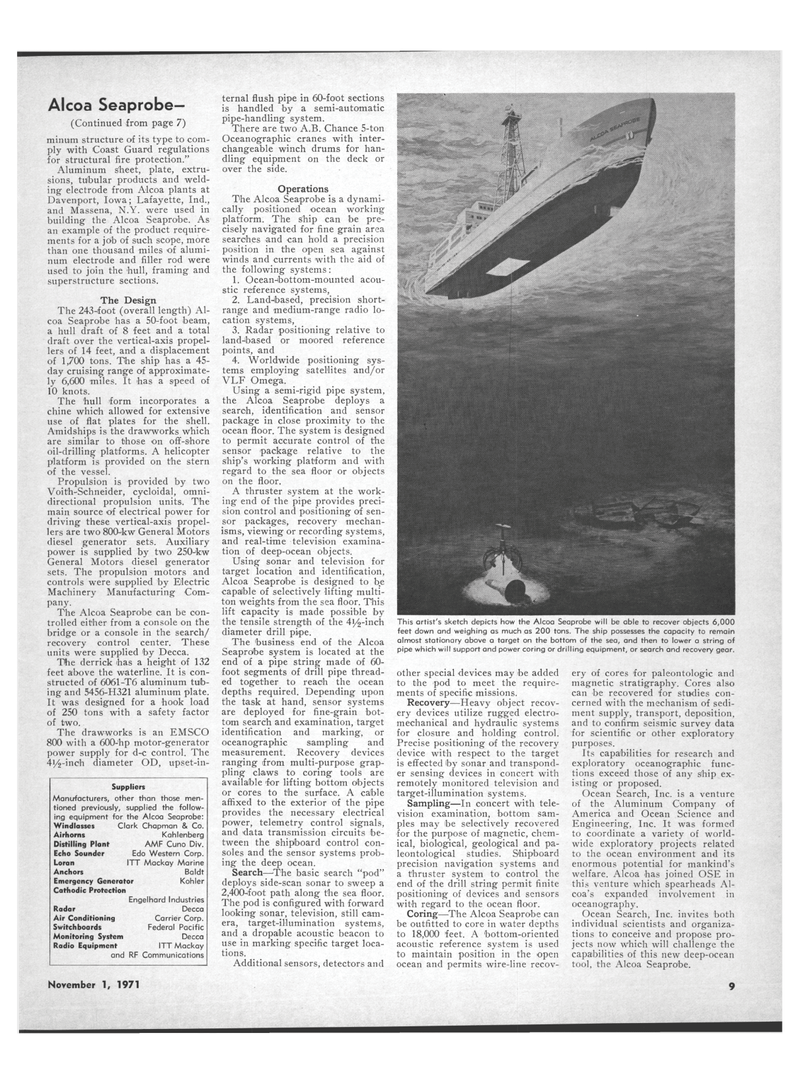

This artist's sketch depicts how the Alcoa Seaprobe will be able to recover objects 6,000 feet down and weighing as much as 200 tons. The ship possesses the capacity to remain almost stationary above a target on the bottom of the sea, and then to lower a string of pipe which will support and power coring or drilling equipment, or search and recovery gear.

November 1, 1971 9

6

6

8

8