Page 19: of Maritime Reporter Magazine (August 1973)

Read this page in Pdf, Flash or Html5 edition of August 1973 Maritime Reporter Magazine

Barge Flotilla Leaves

For Prudhoe Bay

Prefabricated Housing Modules Weighing Up

To 900 Tons, Power Station Modules, And

Large Water Tanks Are Some Of The Heavy

Eguipment That Had To Be 'Walked' Aboard

Barges For The Trip To Alaska's Arctic Coast

Eight massive barges carrying over $30 million worth of cargo were loaded in Seattle, Wash., on July 6, to make a 3,500-mile dash north to

Prudhoe Bay on Alaska's Arctic coast.

The barges, carrying 20,000 tons of cargo for the Standard Oil Company (Ohio) oil operations on the North Slope, are expected to reach their destination by the 15th of this month.

The Arctic ice moves off the Alaska coast for about six weeks midsummer and the barges have to hurriedly drop their loads and head back south to avoid being trapped in the ice for the winter.

Point Barrow, 150 miles west of Prudhoe Bay and the most northernly point in the United States, is virtually an ice trap if the wind is blowing from the north, and the barges may have to wait there for the wind to change and the ice to blow offshore. Last year, conditions were such that the barges taking up supplies had to wait about a week both on the inbound and outbound journeys.

B.P. Alaska Inc., as Prudhoe Bay operators for the Cleveland-based Standard Oil Company, organized the sea lift which is being carried out by Arctic Marine Freighters (AMF). AMF has landed cargo at Prudhoe Bay each year since the discovery of the oil field in 1968.

The cargo this year includes a new 95,000- square-foot operations camp specially designed for

Arctic conditions by Wallace. Floyd, Ellenszweig,

Inc. of Cambridge, Mass., and the first phase of a central power station which will eventually supply all the power needs for the Prudhoe Bay oil field. Two 17 MW gas turbines, each capable of generating 13,800 volts, and a control center with the necessary ancillary equipment, form a major part of the cargo. Also included is a fuel gas system for the camp, which was constructed in Seattle by W.D. Whinery Inc.

General Swalling, a joint venture with Alaska's

Swalling Construction, prefabricated the camp; and Manson-Osberg, another joint venture, built the power plant. Alaskan firms engaged in sub- contract work are Haskell Corp., City Electric

Inc., Swalling Construction Co. Inc., and Holert

Electric Co.

The operations camp, which will be capable of housing 150 men, will cost $18 million by the time it is installed at its North Slope location and linked up with the utilities. "The critical time factors involved in operations in the Arctic and the size and value of the cargo make the whole exercise a very delicate one re- quiring precise planning," said Leo L. Collar, president of Puget Sound Tug and Barge Com- pany, Arctic Marine Freighters' partner in the operation.

The 'base camp is divided into five sections, each 125 feet long, 50 feet wide and 45 feet high.

Since some of the sections weigh up to 900 tons, they cannot be lifted aboard the barges by crane, but must be "walked" aboard by specially de- signed crawler transporters, mini-tractors that fit under the sections, hydraulically lift them and transport them aboard the barges.

The larger of the power station modules are placed on the barges in a similar manner.

When the last of the camp modules was "walked" aboard, the crawlers were left on the barge for use in the delicate unloading operation that will occur at Prudhoe Bay. There, the mod- ules will be transferred to smaller, shallow-draft barges eight miles from the shore because of the four-foot water depth near the coastline. To allow the crawler transporters to transfer the modules, both the oceangoing and shallow-draft barges will be positioned end-to-end in seven feet of water, and then take on water in ballast tanks until they are resting on the bottom. This will secure the barges so the crawlers can make the transfer.

The shallow-draft barges will then be floated and towed to a dock at the end of a 1,100-foot gravel causeway that has been prepared to receive cargo. Once there, the barges will be ballasted again, and crawlers will "walk" the modules off the barges and along a gravel road 20 miles to their locations.

AMF has installed a quick ballast and de-ballast system in the barges to speed up the entire opera- tion. When the flotilla arrives at Prudhoe Bay, the cargo will have to be unloaded quickly to enable the tows to leave before the ice pack moves back to block their way.

Three large water tanks, two diesel tanks, other camp support equipment and over 10,000 tons of miscellaneous supplies were loaded aboard other

AMF barges to sail north in the same flotilla.

Pictured are three large water tanks on an Arctic Marine

Freighters barge loaded at Seattle for the 3,500-mile trip to Alaska's North Slope.

A large low-profile "creepy crawler" moves under the 559-ton camp module (also shown in top picture). The crawler hydraulically lifts the heavy modules up and slowly moves them aboard the barges.

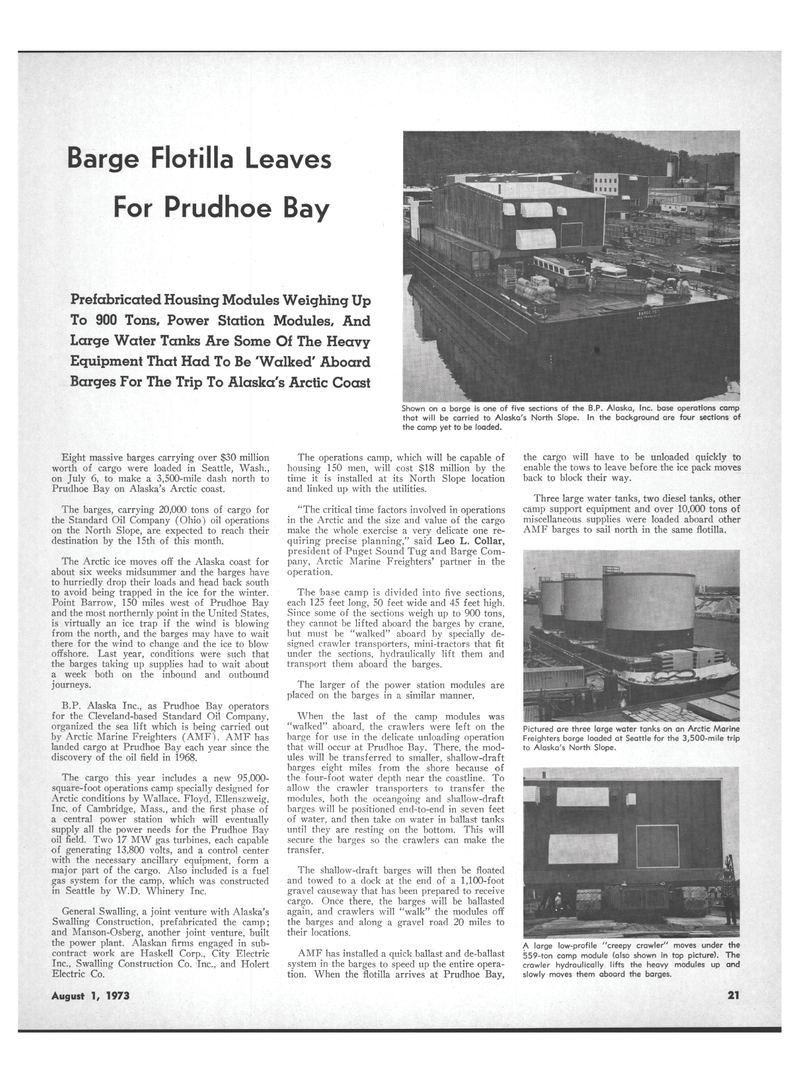

Shown on a barge is one of five sections of the B.P. Alaska, Inc. base operations camp that will be carried to Alaska's North Slope. In the background are four sections of the camp yet to be loaded.

August 1, 1973 21

18

18

20

20