Page 31: of Maritime Reporter Magazine (August 15, 1973)

Read this page in Pdf, Flash or Html5 edition of August 15, 1973 Maritime Reporter Magazine

Nelson Log Bronc Delivers

New Type Clearing Vessel For

Harbor Cleaning/Maintenance

Jack L. Wilskey, president of Nelson Log

Bronc Co., P.O. Box 692, Coos Bay, Ore., has announced that the firm's new ecology oriented debris-clearing vessel, trade-named the "Logster," h^s been working successfully for the Weyer- haeuser Co., one of the nation's leading wood products companies.

The vessel represents more than two years of research into the field of harbor utility vessels, and is believed to be the first and most advanced vessel of this type available as a- stock-manufac- tured product.

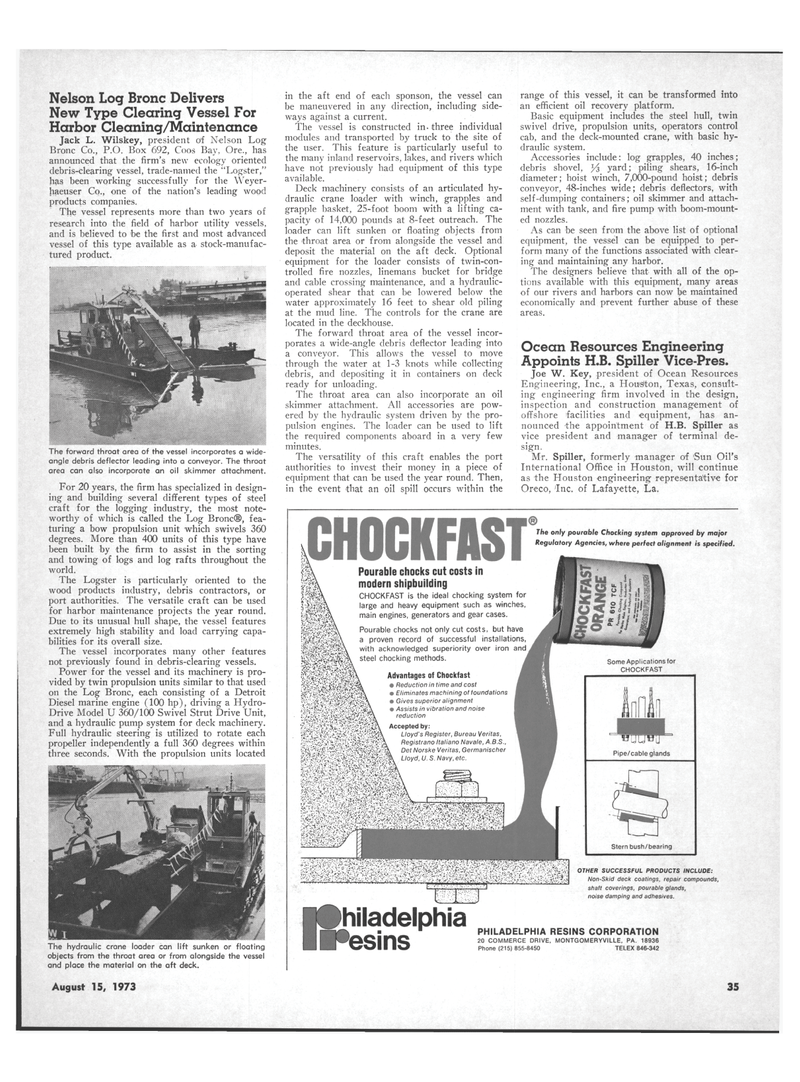

The forward throat area of the vessel incorporates a wide- angle debris deflector leading into a conveyor. The throat area can also incorporate an oil skimmer attachment.

For 20 years, the firm has specialized in design- ing and building several different types of steel craft for the logging industry, the most note- worthy of which is called the Log Bronc®, fea- turing a bow propulsion unit which swivels 360 degrees. More than 400 units of this type have been built by the firm to assist in the sorting and towing of logs and log rafts throughout the world.

The Logster is particularly oriented to the wood products industry, debris contractors, or port authorities. The versatile craft can be used for harbor maintenance projects the year round.

Due to its unusual hull shape, the vessel features extremely high stability and load carrying capa- bilities for its overall size.

The vessel incorporates many other features not previously found in debris-clearing vessels.

Power for the vessel and its machinery is pro- vided by twin propulsion units similar to that used on the Log Bronc, each consisting of a Detroit

Diesel marine engine (100 hp), driving a Hydro-

Drive Model U 360/100 Swivel Strut Drive Unit, and a hydraulic pump system for deck machinery.

Full hydraulic steering is utilized to rotate each propeller independently a full 360 degrees within three seconds. With the propulsion units located

The hydraulic crane loader can lift sunken or floating objects from the throat area or from alongside the vessel and place the material on the aft deck. in the aft end of each sponson, the vessel can be maneuvered in any direction, including side- ways against a current.

The vessel is constructed in-three individual modules and transported by truck to the site of the user. This feature is particularly useful to the many inland reservoirs, lakes, and rivers which have not previously had equipment of this type available.

Deck machinery consists of an articulated hy- draulic crane loader with winch, grapples and grapple basket, 25-foot boom with a lifting ca- pacity of 14,000 pounds at 8-feet outreach. The loader can lift sunken or floating objects from the throat area or from alongside the vessel and deposit the material on the aft deck. Optional equipment for the loader consists of twin-con- trolled fire nozzles, linemans bucket for bridge and cable crossing maintenance, and a hydraulic- operated shear that can be lowered below the water approximately 16 feet to shear old piling at the mud line. The controls for the crane are located in the deckhouse.

The forward throat area of the vessel incor- porates a wide-angle debris deflector leading into a conveyor. This allows the vessel to move through the water at 1-3 knots while collecting debris, and depositing it in containers on deck ready for unloading.

The throat area can also incorporate an oil skimmer attachment. All accessories are pow- ered by the hydraulic system driven by the pro- pulsion engines. The loader can be used to lift the required components aboard in a very few minutes.

The versatility of this craft enables the port authorities to invest their money in a piece of equipment that can be used the year round. Then, in the event that an oil spill occurs within the range of this vessel, it can be transformed into an efficient oil recovery platform.

Basic equipment includes the steel hull, twin swivel drive, propulsion units, operators control cab, and the deck-mounted crane, with basic hy- draulic system.

Accessories include: log grapples, 40 inches; debris shovel, yi yard; piling shears, 16-inch diameter; hoist winch, 7,000-pound hoist; debris conveyor, 48-inches wide; debris deflectors, with self-dumping containers; oil skimmer and attach- ment with tank, and fire pump with boom-mount- ed nozzles.

As can be seen from the above list of optional equipment, the vessel can be equipped to per- form many of the functions associated with clear- ing and maintaining any harbor.

The designers believe that with all of the op- tions available with this equipment, many areas of our rivers and harbors can now be maintained economically and prevent further abuse of these areas.

Ocean Resources Engineering

Appoints H.B. Spiller Vice-Pres.

Joe W. Key, president of Ocean Resources

Engineering, Inc., a Houston, Texas, consult- ing engineering firm involved in the design, inspection and construction management of offshore facilities and equipment, has an- nounced the appointment of H.B. Spiller as vice president and manager of terminal de- sign.

Mr. Spiller, formerly manager of 'Sun Oil's

International Office in Houston, will continue as the Houston engineering representative for

Oreco, 'Inc. of Lafayette, La.

CHOCKFAST The only pourable Chocking system approved by major Regulatory Agencies, where perfect alignment is specified.

Stern bush/bearing

OTHER SUCCESSFUL PRODUCTS INCLUDE:

Non-Skid deck coatings, repair compounds, shaft coverings, pourable glands, noise damping and adhesives. hiladelphia esins

PHILADELPHIA RESINS CORPORATION 20 COMMERCE DRIVE, MONTGOMERYVILLE, PA. 18936

Phone (215) 855-8450 TELEX 846-342

August 35, 1973 13

30

30

32

32