Page 25: of Maritime Reporter Magazine (October 15, 1973)

Read this page in Pdf, Flash or Html5 edition of October 15, 1973 Maritime Reporter Magazine

Gale C. Named For Veteran Riverman

Christened In Ceremonies At St. Louis Ship

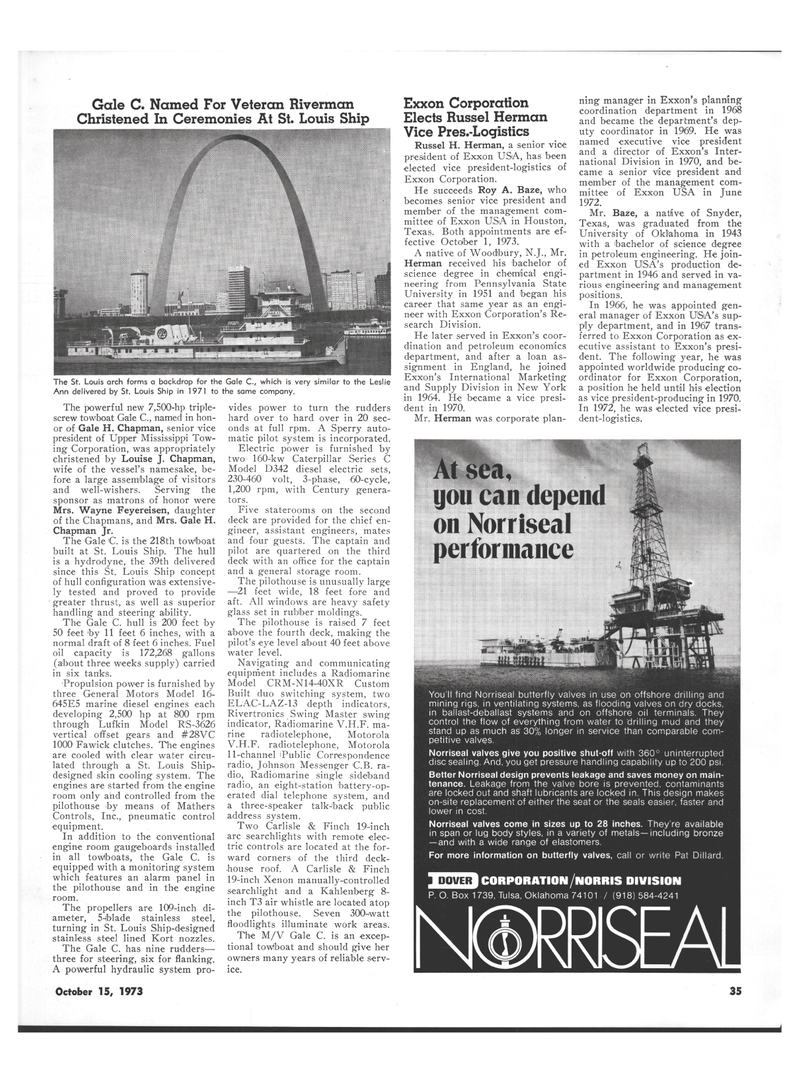

The St. Louis arch forms a backdrop for the Gale C., which is very similar to the Leslie

Ann delivered by St. Louis Ship in 1971 to the same company.

The powerful new 7,500-hp triple- screw towboat Gale C., named in hon- or of Gale H. Chapman, senior vice president of Upper Mississippi Tow- ing Corporation, was appropriately christened by Louise J. Chapman, wife of the vessel's namesake, be- fore a large assemblage of visitors and well-wishers. Serving the sponsor as matrons of honor were

Mrs. Wayne Feyereisen, daughter of the Chapmans, and Mrs. Gale H.

Chapman Jr.

The Gale C. is the 218th towboat built at St. Louis Ship. The hull is a hydrodyne, the 39th delivered since this St. Louis Ship concept of hull configuration was extensive- ly tested and proved to provide greater thrust, as well as superior handling and steering ability.

The Gale C. hull is 200 feet by 50 feet by 11 feet 6 inches, with a normal draft of 8 feet 6 inches. Fuel oil capacity is 172,268 gallons (about three weeks supply) carried in six tanks.

Propulsion power is furnished by three General Motors Model 16- 645E5 marine diesel engines each developing 2,500 hp at 800 rpm through Lufkin Model RS-3626 vertical offset gears and #28VC 1000 Fawick clutches. The engines are cooled with clear water circu- lated through a St. Louis Ship- designed skin cooling system. The engines are started from the engine room only and controlled from the pilothouse by means of Mathers

Controls, Inc., pneumatic control equipment.

In addition to the conventional engine room gaugeboards installed in all towtboats, the Gale C. is equipped with a monitoring system which features an alarm panel in the pilothouse and in the engine room.

The propellers are 109-inch di- ameter, 5-iblade stainless steel, turning in St. Louis Ship-designed stainless steel lined Kort nozzles.

The Gale C. has nine rudders— three for steering, six for flanking.

A powerful hydraulic system pro- vides power to turn the rudders hard over to hard over in 20 sec- onds at full rpm. A Sperry auto- matic pilot system is incorporated.

Electric power is furnished by two 160-kw Caterpillar Series C

Model D342 diesel electric sets, 230-460 volt, 3-phase, 60-cycle, 1,200 rpm, with Century genera- tors.

Five staterooms on the second deck are provided for the chief en- gineer, assistant engineers, mates and four guests. The captain and pilot are quartered on the third deck with an office for the captain and a general storage room.

The pilothouse is unusually large —21 feet wide, 18 feet fore and aft. All windows are heavy safety glass set in rubber moldings.

The pilothouse is raised 7 feet above the fourth deck, making the pilot's eye level about 40 feet above water level.

Navigating and communicating equipment includes a Radiomarine

Model CRM-N14-40XR Custom

Built duo switching system, two

ELAC-LAZ-13 depth indicators,

Rivertronics Swing Master swing indicator, Radiomarine V.H.F. ma- rine radiotelephone, Motorola

V.H.F. radiotelephone, Motorola 11-channel iPublic Correspondence radio, Johnson Messenger C.B. ra- dio, Radiomarine single sideband radio, an eight-station 'battery-op- erated dial telephone system, and a three-speaker talk-back public address system.

Two Carlisle & Finch 19-inch arc searchlights with remote elec- tric controls are located at the for- ward corners of the third deck- house roof. A Carlisle & Finch 19-inch Xenon manually-controlled searchlight and a Kahlenberg 8- inch T3 air whistle are located atop the pilothouse. Seven 300^watt floodlights illuminate work areas.

The M/V Gale C. is an excep- tional towlboat and should give her owners many years of reliable serv- ice.

Exxon Corporation

Elects Russel Herman

Vice Pres.-Logistics

Russel H. Herman, a senior vice president of Exxon USA, has been elected vice president-logistics of

Exxon Corporation.

He succeeds Roy A. Baze, who becomes senior vice president and member of the management com- mittee of Exxon USA in Houston,

Texas. Both appointments are ef- fective October 1, 1973.

A native of Woodbury, N.J., Mr.

Herman received his bachelor of science degree in chemical engi- neering from Pennsylvania State

University in 1951 and began his career that same year as an engi- neer with Exxon Corporation's Re- search Division.

He later served in Exxon's coor- dination and petroleum economics department, and after a loan as- signment in England, he joined

Exxon's International Marketing and Supply Division in New York in 1964. He became a vice presi- dent in 1970.

Mr. Herman was corporate plan- ning manager in Exxon's planning coordination department in 1968 and became the department's dep- uty coordinator in 1969. He was named executive vice president and a director of Exxon's Inter- national Division in 1970, and be- came a senior vice president and member of the management com- mittee of Exxon USA in June 1972.

Mr. Baze, a native of Snyder,

Texas, was graduated from the

University of Oklahoma in 1943 with a bachelor of science degree in petroleum engineering. He join- ed Exxon USA's production de- partment in 1946 and served in va- rious engineering and management positions.

In 1966, he was appointed gen- eral manager of Exxon USA's sup- ply department, and in 1967 trans- ferred to Exxon Corporation as ex- ecutive assistant to Exxon's presi- dent. The following year, he was appointed worldwide producing co- ordinator for Exxon Corporation, a position he held until his election as vice president-producing in 1970.

In 1972, he was elected vice presi- dent-logistics. you can depen on Norriseal illlllllll

You'll find Norriseal butterfly valves in use on offshore drilling and mining rigs, in ventilating systems, as flooding valves on dry docks, in ballast-deballast systems and on offshore oil terminals. They control the flow of everything from water to drilling mud and they stand up as much as 30% longer in service than comparable com- petitive valves.

Norriseal valves give you positive shut-off with 360° uninterrupted disc sealing. And, you get pressure handling capability up to 200 psi.

Better Norriseal design prevents leakage and saves money on main- tenance. Leakage from the valve bore is prevented, contaminants are locked out and shaft lubricants are locked in. This design makes on-site replacement of either the seat or the seals easier, faster and lower in cost.

Norriseal valves come in sizes up to 28 inches. They re available in span or lug body styles, in a variety of metals—including bronze —and with a wide range of elastomers.

For more information on butterfly valves, call or write Pat Dillard.

XEZO CORPORATION /NORMS DIVISION

P. O. Box 1739, Tulsa, Oklahoma 74101 / (918)584-4241

October 15, 1973 11

24

24

26

26