Page 41: of Maritime Reporter Magazine (September 1974)

Read this page in Pdf, Flash or Html5 edition of September 1974 Maritime Reporter Magazine

Marine Industries Gets $20-Million Tanker Order

From Gulf Oil Canada

A $20-million order for two ice- strengthened oil tankers has been received by Marine Industries,

Ltd., Sorel, Quebec, Canada, from

Gulf Oil Canada Ltd., which is 69-percent owned by Gulf Oil

Corp., Pittsburgh, Pa. The 68,000- barrel tankers—scheduled for delivery in late 1976—will be used to supply petroleum products to the lower St. Lawrence River, the

Maritime Provinces, and New- foundland. The price of the order includes a $3-million Canadian

Government construction subsidy.

Hyde Appoints Four As

Product Group Managers

In line with Hyde Products' rapid growth as a designer and producer of marine machinery, plus pollution control equipment and chemicals for a wide range of industrial and marine applica- tions, the company has appointed four product group managers to direct and implement these func- tions. The announcement was made by Thomas P. Mackey Jr.,

Hyde president.

Parker L. Hay was appointed group manager in charge of the extensive Hyde line of marine machinery, including steering gears, anchor windlasses, moor- ing winches, chocks, and cargo winches for both lake and ocean vessels. The line includes virtu- ally all mechanical systems ex- cept main propulsion gear. In ad- dition, Mr. Hay has assumed the duties of chief engineer for Hyde

Products.

Mr. Hay, who attended Union

University and Southern Baptist

College, joined Hyde in 1969 as a project engineer. Prior to that, he was a field engineer with J.J.

Henry Co., Inc., and a mechanical designer for General Dynamics

Corporation's Electric Boat Divi- sion. He is a member of The So- ciety of Naval Architects and

Marine Engineers.

Edward L. Heidenreich has been named group manager re- sponsible for all activities relat- ing to Hyde's marine and indus- trial pollution control equipment.

These products include oil-water separators, waste treatment sys- tems, and water quality monitors.

Mr. Heidenreich, who received his education at Purdue Univer- sity, came to Hyde in 1971. Be- fore that, he was a piping systems designer at Adache Associates and a design engineer at Compre- hensive Design, Inc. At one time, he was also a designer of marine piping and ventilation for Amer- ican Shipbuilding Company.

Thomas Braid has been ap- pointed group manager in charge of Hyde's growing line of spe- cialty marine chemicals, as well as the company's popular Zimmite

Mud Remover for shipboard bal- last tanks and similar marine ap- plications. Mr. Braid's new re- sponsibilities will also include coordinating customer service ac- tivities for all Hyde's marine products, as well as the applica- tion of marine chemicals to the company's marine pollution con- trol systems.

Mr. Braid joined Hyde in 1973 as manager of marine products.

Formerly, he was assistant ma- rine superintendent at the Kins- man Marine Transit Company. A native of Scotland, Mr. Braid was educated at Glasgow Technical

College.

Paul J. Blonski was appointed group manager responsible for the maintenance, stocking and furnishing of repair parts for

Hyde's entire line of marine ma- chinery, including deck machinery as well as marine sewage dis- posal systems, oil-water separa- tors, and pumping systems and accessories. His responsibilities will also include all activities in- volving the Hyde Stream-Stay®, a unique grooved headstay which is being distributed nationally, and other Hyde yacht equipment.

Mr. Blonski, who attended Kent

State University, came to Hyde

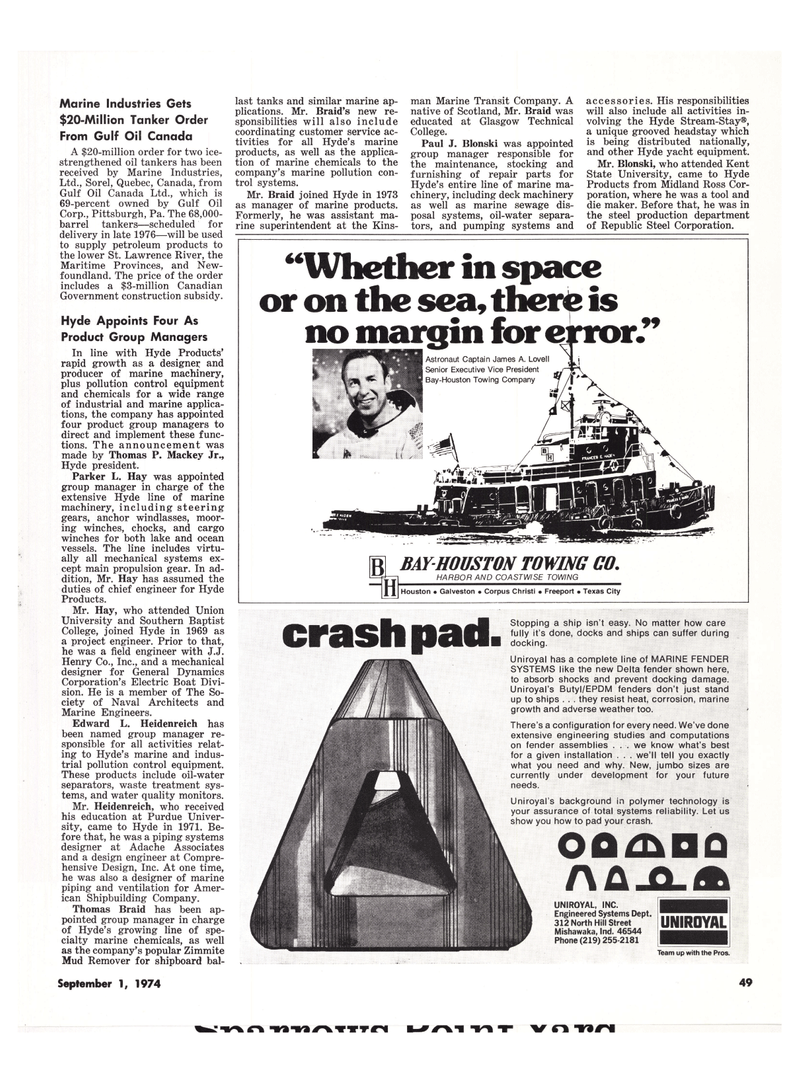

Products from Midland Ross Cor- poration, where he was a tool and die maker. Before that, he was in the steel production department of Republic Steel Corporation. "Whether in space or on the sea, there is no margin for error'9 iRl BAY HOUSTON TOWING CO. RJ uadd/^D A M r> r^r^ A CTU// CC T/~HA/iMr*

H HARBOR AND COASTWISE TOWING Houston • Galveston • Corpus Christi • Freeport • Texas City crash pad. Stopping a ship isn't easy. No matter how care fully it's done, docks and ships can suffer during docking.

Uniroyal has a complete line of MARINE FENDER

SYSTEMS like the new Delta fender shown here, to absorb shocks and prevent docking damage.

Uniroyal's Butyl/EPDM fenders don't just stand up to ships . . . they resist heat, corrosion, marine growth and adverse weather too.

There's a configuration for every need. We've done extensive engineering studies and computations on fender assemblies ... we know what's best for a given installation . . . we'll tell you exactly what you need and why. New, jumbo sizes are currently under development for your future needs.

Uniroyal's background in polymer technology is your assurance of total systems reliability. Let us show you how to pad your crash.

OO^DQ

UNIROYAL, INC.

Engineered Systems Dept. 312 North Hill Street

Mishawaka, Ind. 46544

Phone (219) 255-2181

Team up with the Pros.

September 1, 1974 19

40

40

42

42